Antirust air nail gun

An air nail gun and gun nail technology, which is applied in nailing tools, nail staple tools, manufacturing tools, etc., can solve the problems of easy oxidation of gun nails and difficult handling by painters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

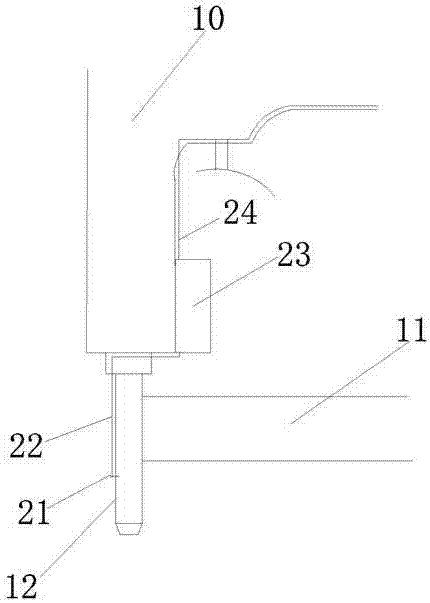

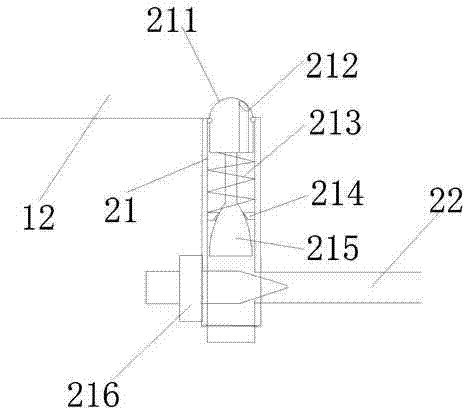

[0013] A kind of anti-rust air nail gun, comprising gun head, nail channel, nail bin, cylinder and compressed air switch, described anti-rust air nail gun is provided with automatic spraying device, and described automatic spraying device comprises sealable anti-rust oil tank, Oil delivery pipe and fuel injection valve; the anti-rust oil tank is set inside the gun body of the anti-rust air nail gun, and the top is provided with a compressed air inlet, which is directly connected to the cylinder through the compressed air pipeline; the oil delivery pipe is connected to the anti-rust oil tank and the oil injection valve The fuel injection valve is arranged on the top of the inner wall of the nail channel between the gun nail outlet of the gun head and the nail bin, including the valve sleeve and the extrusion head of the fuel injection valve, the return spring of the extrusion head of the fuel injection valve, the fuel injection valve, The fuel injection valve core and the oil ci...

Embodiment 2

[0015] A kind of anti-rust air nail gun, comprising gun head, nail channel, nail bin, cylinder and compressed air switch, described anti-rust air nail gun is provided with automatic spraying device, and described automatic spraying device comprises sealable anti-rust oil tank, Oil delivery pipe and fuel injection valve; the anti-rust oil tank is arranged in the body of the anti-rust air nail gun, the top of the anti-rust oil tank is provided with a compressed air inlet, and the compressed air switch is connected with the anti-rust air nail gun through the compressed air pipeline. The compressed air pump is connected; the oil pipeline is connected to the anti-rust oil tank and the fuel injection valve; the fuel injection valve is set on the inner wall side of the nail path between the gun nail outlet of the gun head and the nail bin, including the valve sleeve and the extrusion head of the fuel injection valve , the return spring of the extrusion head of the fuel injection valve...

Embodiment 3

[0017] A kind of anti-rust air nail gun, including gun head, nail channel, nail bin, cylinder and compressed air switch, and automatic spraying device, automatic spraying device includes sealable anti-rust oil tank, oil delivery pipe and oil injection valve; The rust oil tank is set outside the anti-rust air nail gun, and the top of the anti-rust oil tank is provided with a compressed air inlet, and is connected to the compressed air pump of the anti-rust air nail gun through a compressed air pipeline through a compressed air switch; the oil pipeline is connected to the anti-rust oil tank and the fuel injection valve; the fuel injection valve is arranged on the top of the inner wall of the nail channel between the gun nail outlet of the gun head and the nail bin, including the valve sleeve and the extrusion head of the fuel injection valve, the return spring of the extrusion head of the fuel injection valve, Fuel injection valve, fuel injection valve core and oil circuit contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com