Efficient and continuous offshore wind power unit foundation grouting stirring system

An offshore wind power and basic grouting technology, which is applied in cement mixing devices, raw material supply devices for sale, clay preparation devices, etc., can solve problems such as affecting mixing quality, limited operating space, and damage to mixing devices, and achieve efficient continuous work and service life. Long, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

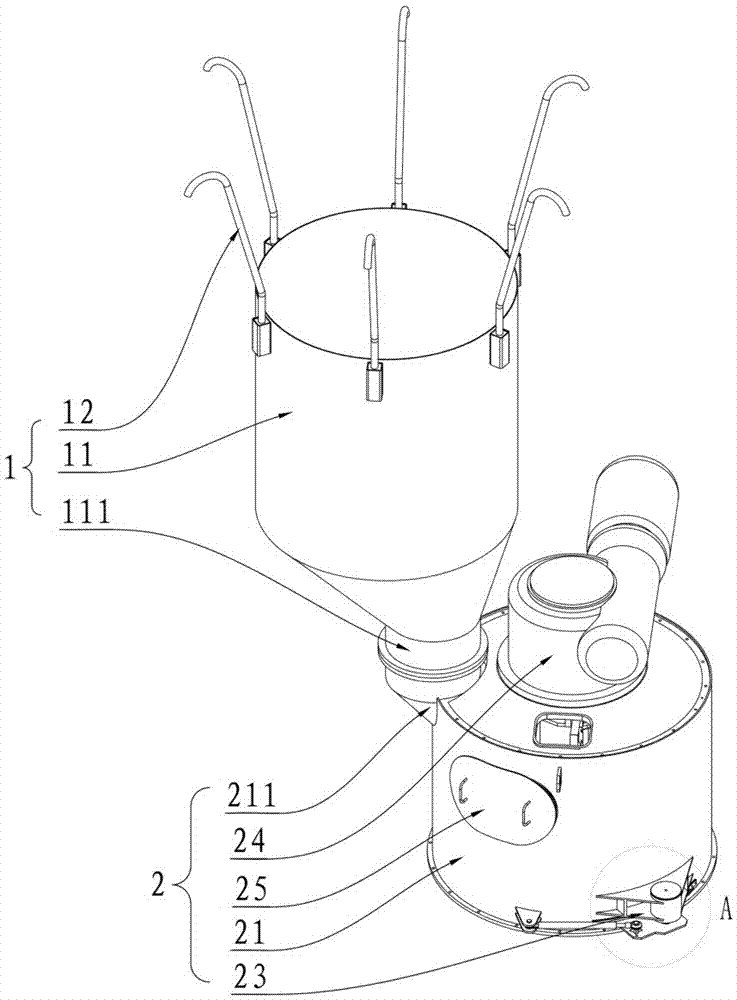

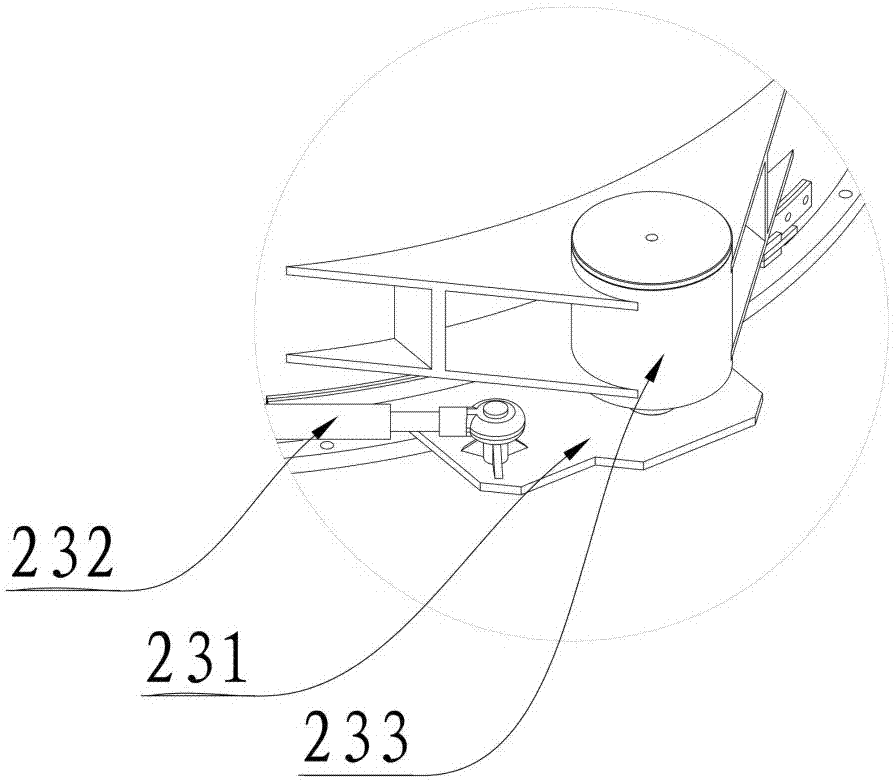

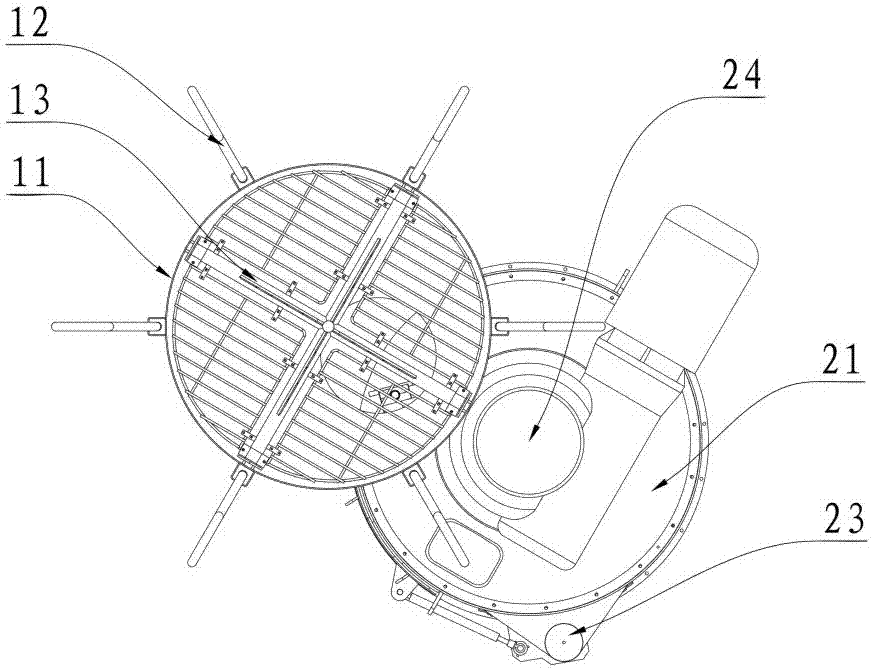

[0020] See attached figure 1 to attach Figure 9 As shown, in this embodiment, a high-efficiency continuous offshore wind turbine foundation grouting and mixing system includes a feeding mechanism 1 and a stirring mechanism 2 . The feed mechanism 1 includes a feed tank 11, an unpacking assembly 12 arranged in the feed tank 11, and six guide rods 12 annularly arranged on the outer surface of the feed port of the feed tank 11, wherein the six guide rods The material rod 12 is in the shape of a bell mouth, and the bagged cement can be more accurately aligned with the feed port of the feeding tank 11 by being provided with the material guide rod 12, so as to prevent the bagged cement from being stuck at the feed port of the feeding tank 11. The unpacking assembly 12 includes a "ten"-shaped installation base 131, a knife rest part 132 composed of four annularly distributed inclin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap