Charging guiding device of burling frame

A guiding device and material feeding technology, which is applied in the direction of thin material processing, transportation and packaging, winding strips, etc., can solve problems such as unevenness, influence of cloth repairing, irregular placement of filter cloth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

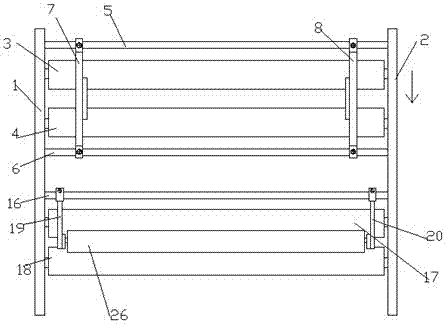

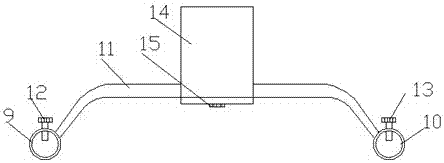

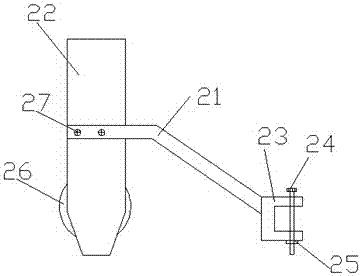

[0026] like Figure 1-3 As shown, the technical solution of the present invention is a feeding guide device for a cloth repairing machine, which includes a left support plate 1 and a right support plate 2, and a limit mechanism is sequentially arranged between the left and right support plates along the filter cloth conveying direction , flattening mechanism,

[0027] Described limit mechanism comprises first limit roller 3, second limit roller 4, and described first limit roller 3, second limit roller 4 are arranged in parallel, first limit roller 3, second limit roller Positioning rollers 4 are moved between the left and right support plates through the first limit shaft and the second limit shaft respectively. The first limit shaft passes through the left support plate 1 and is connected with the stepping motor. The outer sides of the first limit roller 3 and the second limit roller 4 are respectively provided with a first guide rod 5 and a second guide rod 6, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com