Width-adjustable conveying device

A technology of conveying device and width, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of increasing equipment cost, material positioning problems, insufficient conveying track to convey large materials, etc., to improve the versatility, Applicable to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

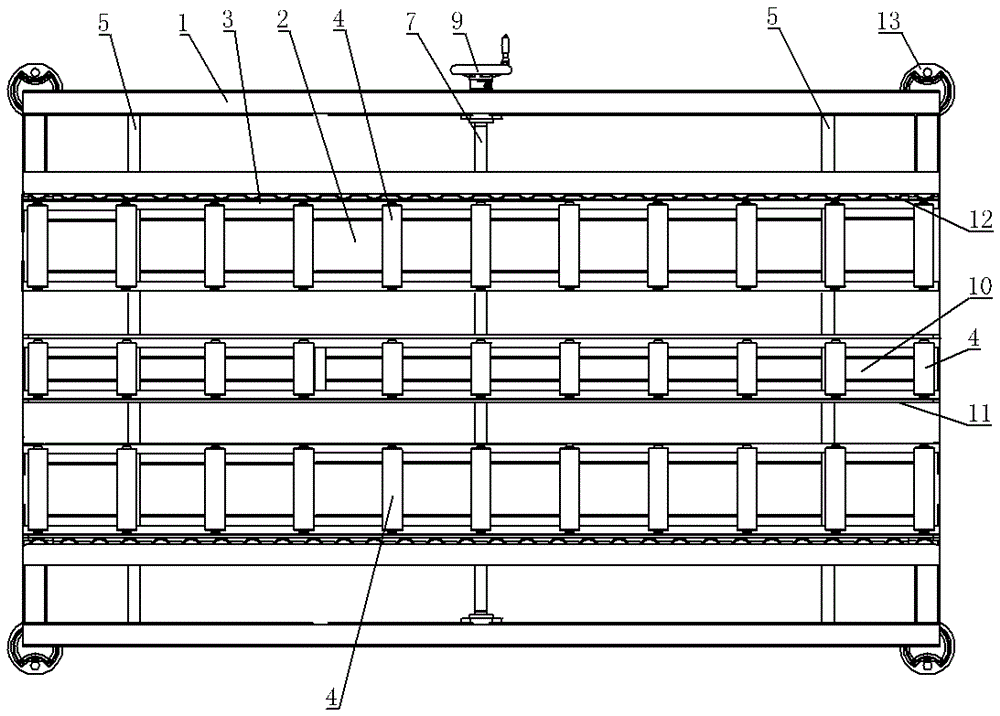

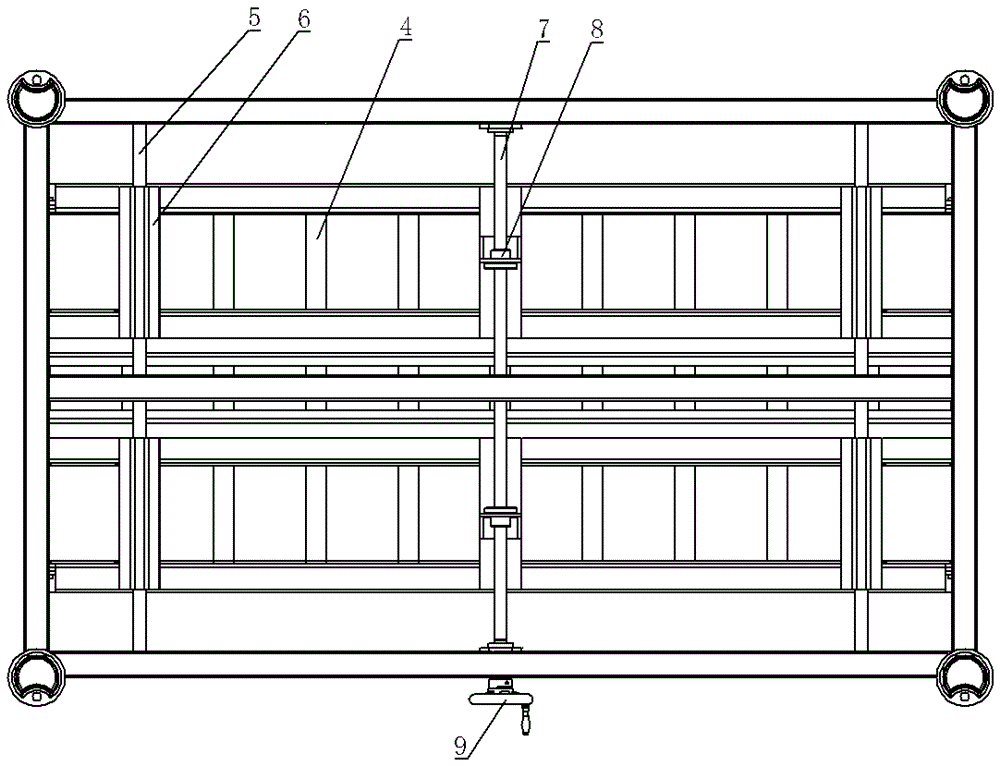

[0016] See figure 1 , figure 2 , a kind of width-adjustable conveying device of the present invention comprises frame 1, and two conveying lines 2 are arranged side by side along the length direction of frame 1 on frame 1, and conveying line 2 comprises that is arranged along the length direction of frame 1 Guide rails 3, guide rollers 4 are arranged at intervals on the guide rails, the guide rollers 4 are rotatably installed between the guide rails 3, slide rails 5 are provided on the frame 1 along the width direction of the frame 1, and the lower ends of the conveying line 2 are respectively A slide block 6 is provided, and the slide block 6 is slidingly matched with the slide rail 5. There are two slide rails 5, and the two slide rails 5 are respectively arranged on the two ends of the frame 1, and the two ends of each conveying line 2 are correspondingly provided with Slider 6 and slide rail 5 are slidably matched, and screw rod 7 is arranged parallel to slide rail 5 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com