Manufacturing method for Buddha handiwork

A production method and technology for handicrafts, applied in clay products, applications, household appliances, etc., can solve the problems of low yield and difficulty in guaranteeing the artistic quality of Buddha Zun porcelain handicrafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

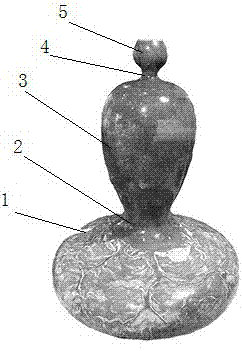

[0013] In order to further illustrate the technical scheme of the present invention, the specific implementation of the present invention is now described in conjunction with examples; figure 1 In this example, the total height of the Buddhist Jun porcelain handicraft is 550 mm; the maximum diameter of the lower cavity 1 is 300 mm, and the height is 180 mm; the height of the middle abdomen 2 is 30 mm and the outer diameter is 80 mm; 120 mm; the height of the upper abdomen 4 is 30 mm, and the outer diameter is 30 mm; the height of the top cup is 50 mm, and the maximum diameter is 50 mm; the overall wall thickness is 7 mm as an example; the pottery clay of the West Temple in Shenhou Town, Yuzhou City is selected as the blank The raw material used in this example is a composite clay, or a single type of pottery clay; it is pulverized and sieved into a 200-mesh fine powder, mixed with water to make it a semi-soft mud, and the semi-soft mud is this The hardness index of the semi-so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com