Remaining Life Prediction Method for Long-Range Correlation Degradation Process Depending on Time and State

A life prediction and time technology, applied in design optimization/simulation, instrumentation, calculation, etc., can solve problems such as difficult parameter estimation, difficult to obtain first-arrival time distribution, and inability to write likelihood functions, etc., to achieve accurate estimation results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

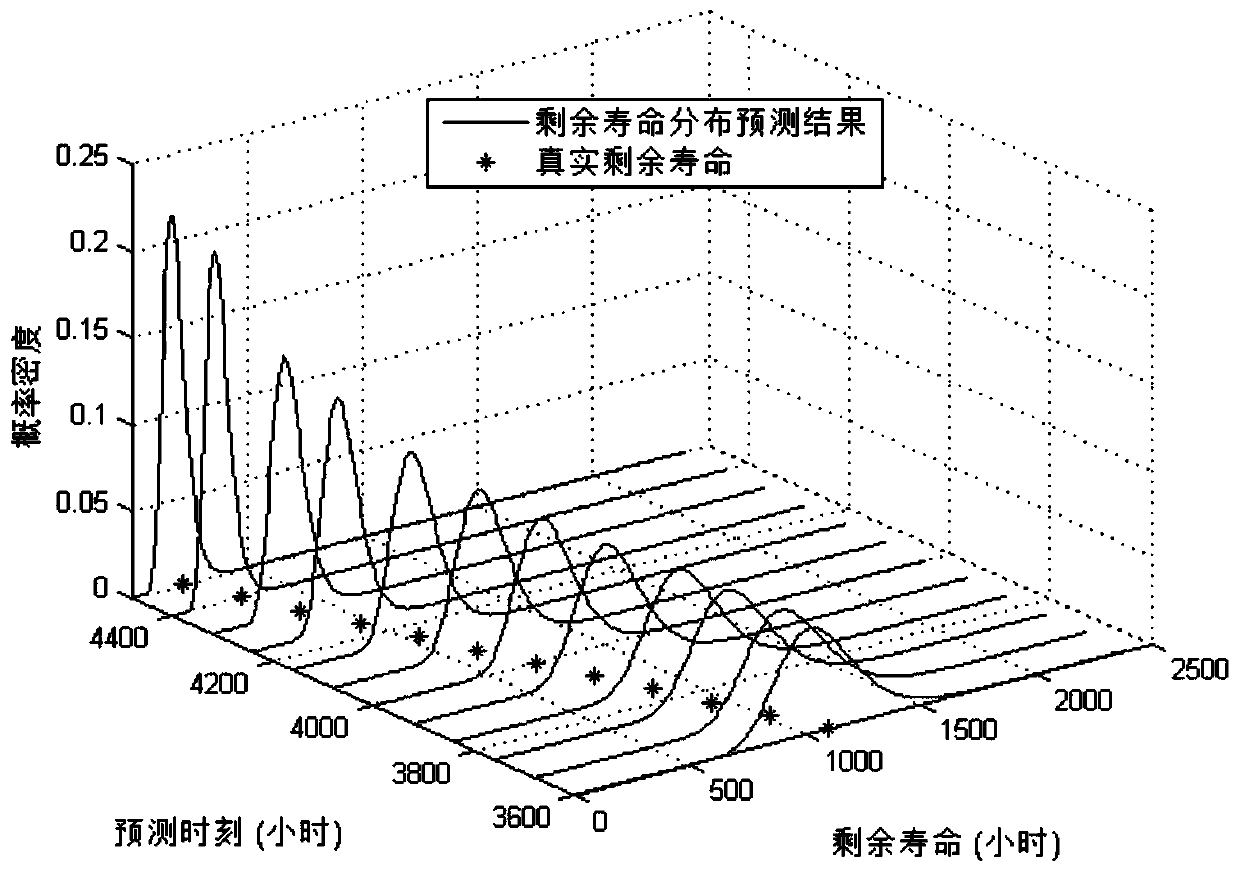

[0046] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

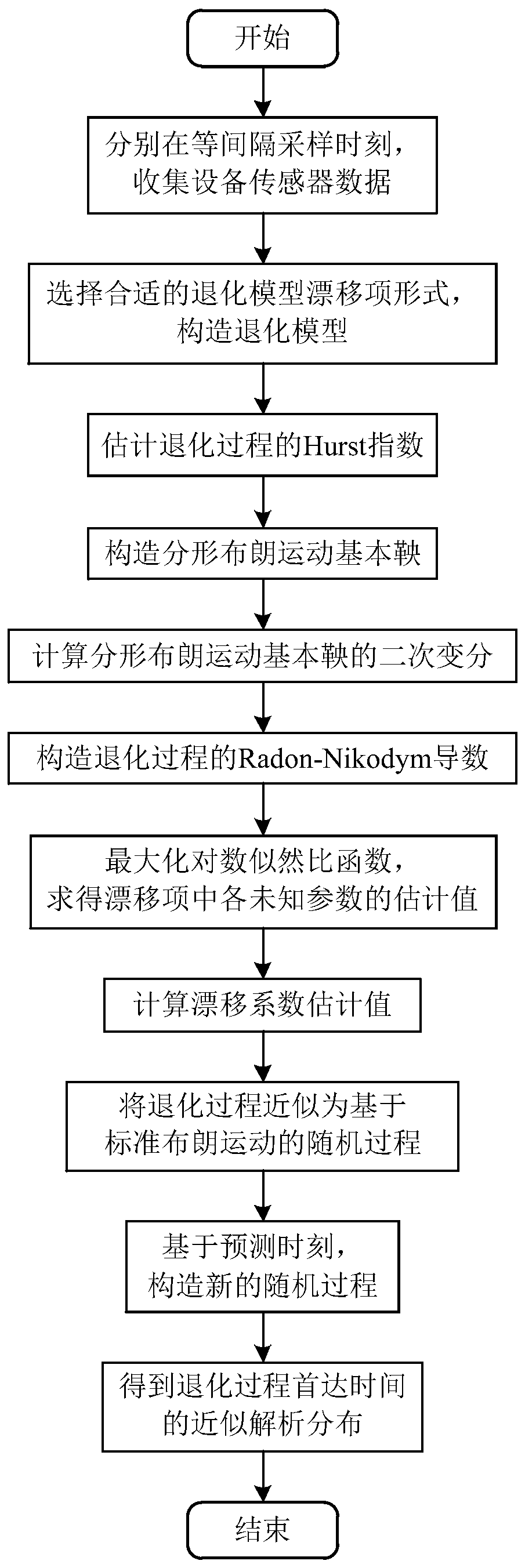

[0047] A method for predicting the remaining life of a long-range correlation degradation process dependent on time and state proposed by the present invention, the process is as follows figure 1 Shown:

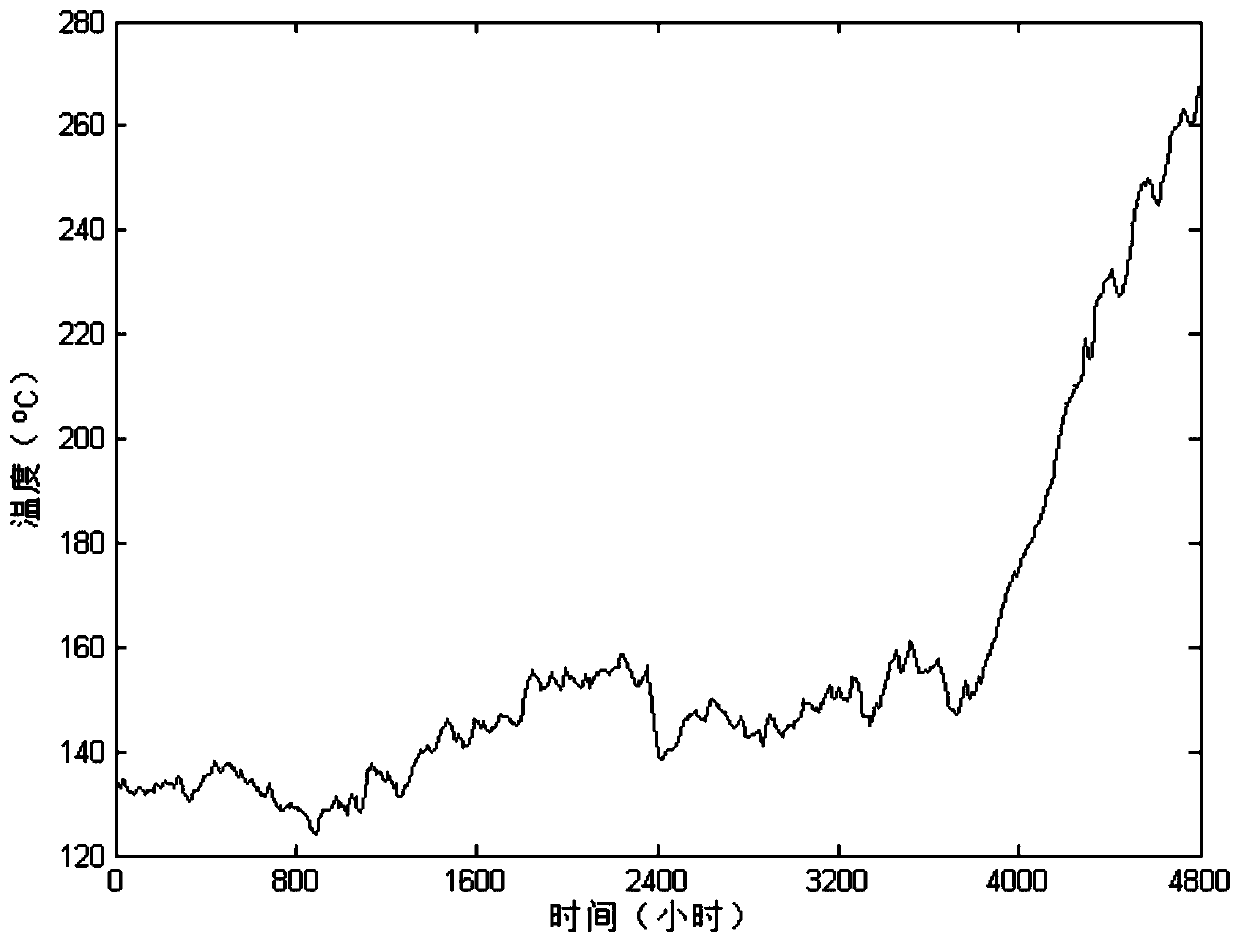

[0048] Step 1: Sampling time t at equal intervals respectively 0 ,t 1 ,t 2 ,...,t k , collect temperature sensor data inside the blast furnace wall x 0 ,x 1 ,x 2 ,...,x k , where k is the number of samples;

[0049] Step 2: Establish a degradation model based on fractal Brownian motion based on the collected temperature sensor data characteristics inside the blast furnace wall, as shown in formula (1):

[0050] dX(t)=μ[X(t),t; θ]dt+σ H dB H (t)(1);

[0051]Among them, X(t) is the degradation process, μ[X(t),t;θ] is the coefficient of the drift term, θ is a vector composed of unknown parameters contained in the coefficient of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com