Radial carbon commutator and method of manufacturing the same

A manufacturing method and commutator technology, which are applied in the field of commutators, can solve the problem that radial commutators cannot simultaneously improve the strength and stability of carbonaceous cylinders and metal conductor blanks, and achieve increased welding area, The effect of improving strength stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

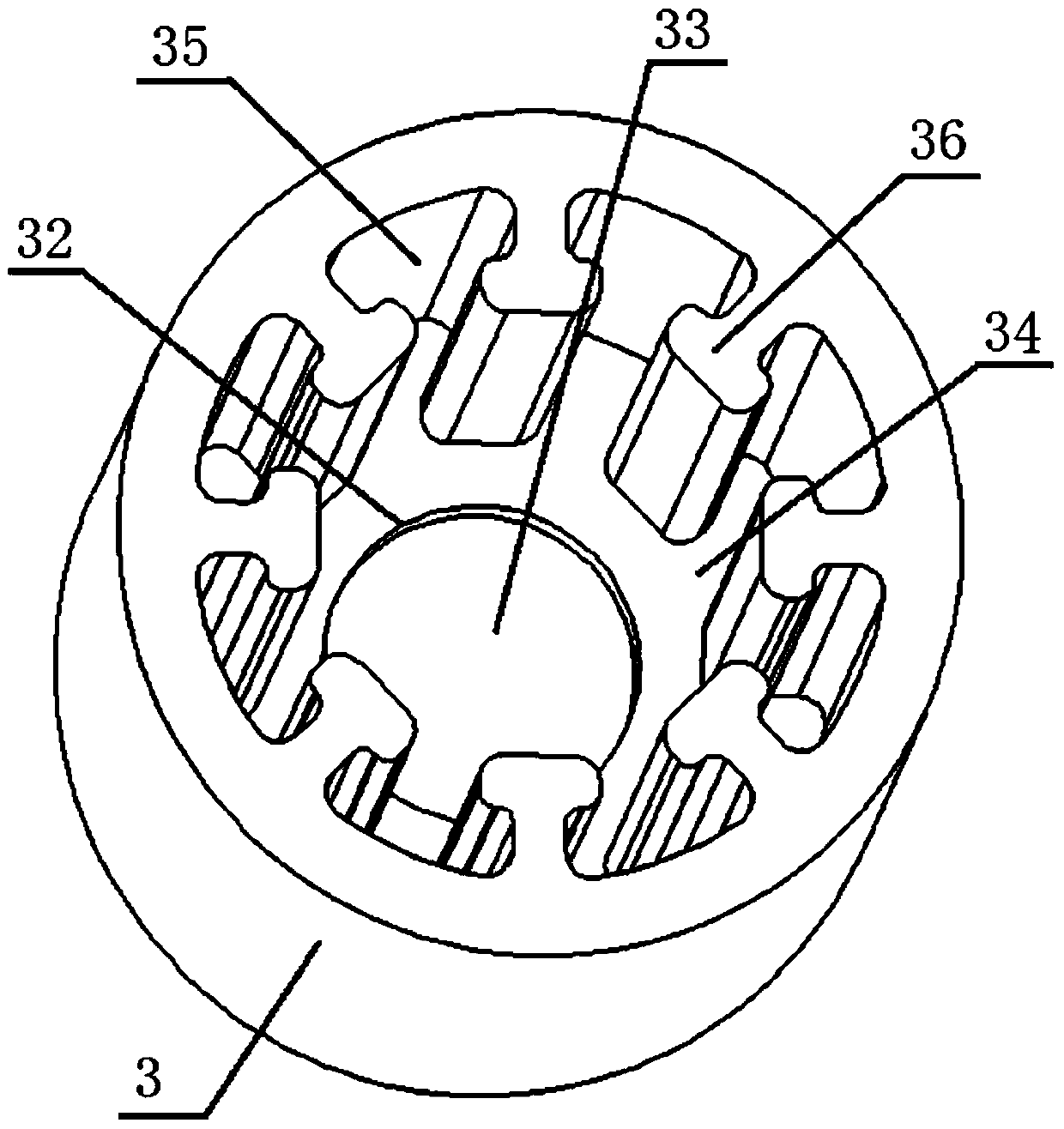

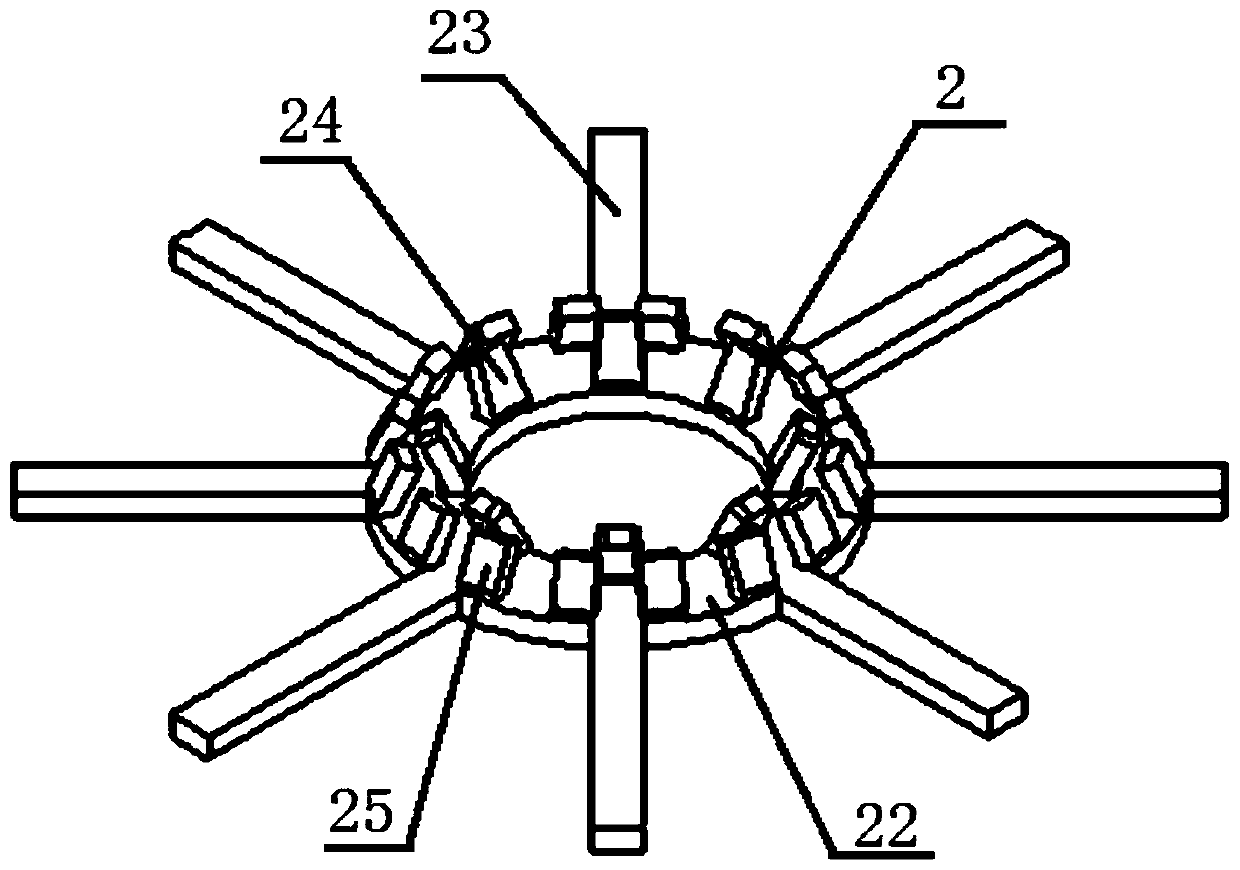

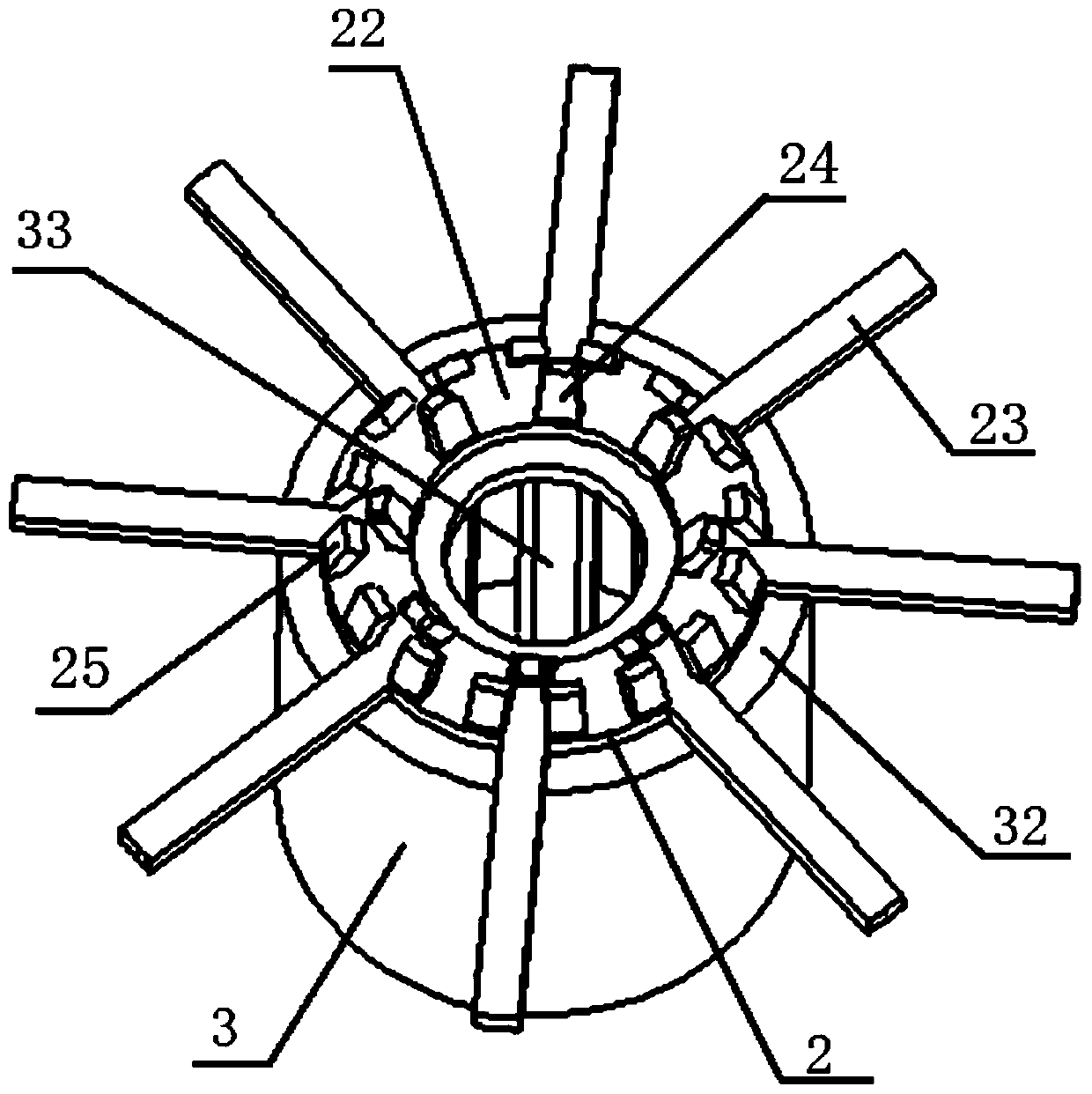

[0069] This embodiment provides a radial carbon commutator, such as Figure 1 to Figure 8 As shown, it includes a cylindrical support body 1 made of insulating material, a plurality of metal conductor connecting pieces 21 and the same number of carbonaceous arc-shaped bodies 31 electrically connected with these metal conductor connecting pieces 21, the radial commutation The device has an annular closed cylindrical surface 11, a carbonaceous arc body 31 surrounds a carbonaceous cylinder 3 with a plurality of second slots 42, and a plurality of carbonaceous arcuate bodies 31 are connected to a plurality of metal conductors The axial end face of the sheet 21 conductively connected is a closed end face 32, and the other end is open. Opening to the closed end face 32 forms an empty cup chamber 34 for accommodating the support body 1, and the center of the closed end face 32 is provided with a diameter smaller than an empty cup. The through hole 33 of the inner diameter of the cavi...

Embodiment 2

[0083] like Figure 1 to Figure 8 As shown, the present embodiment provides a manufacturing method of a radial carbon commutator, which has a cylindrical support body 1 made of insulating material, a plurality of metal conductor connecting pieces 21 and the same number The carbonaceous arc-shaped body 31 conductively connected with these metal conductor connecting pieces 21, the radial carbonaceous commutator has an annular closed cylindrical surface 11 that is alternately insulating regions and conductive regions, the method includes the following steps The above steps:

[0084] S1: Manufacture a carbonaceous cylinder 3 whose outer surface is substantially cylindrical, the carbonaceous cylinder 3 is manufactured such that one end along its axial direction is provided with a closed end face 32, and the opposite end along the axial direction is open, Open to the closed end face 32 to form an empty cup cavity 34, the central part of the closed end face 32 offers a through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com