Toy train

A train and toy technology, applied in the field of toy trains, can solve the problems of lack of interest, reduce children's attractiveness, and poor effect, and achieve the effect of increasing interest, simple operation, and strong interest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

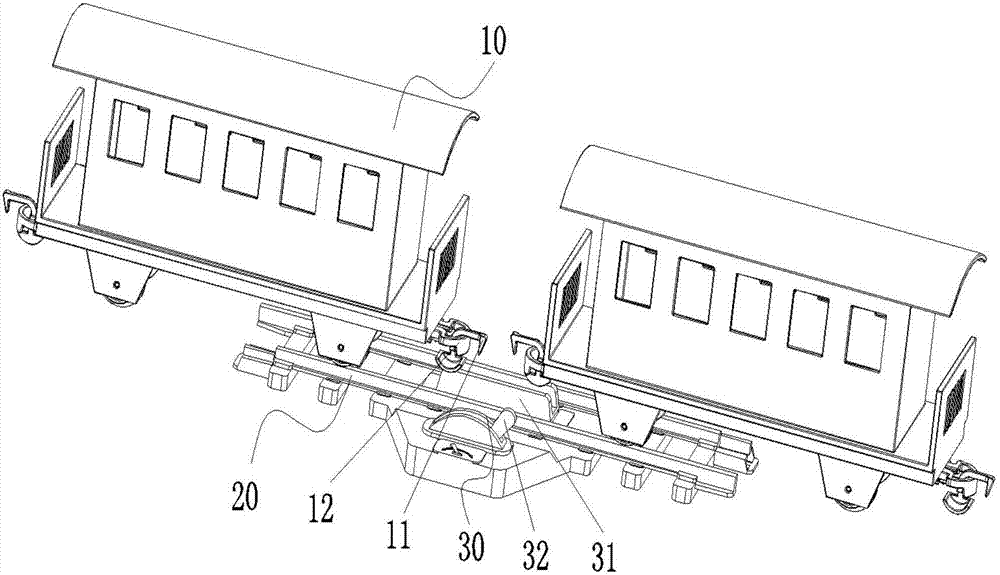

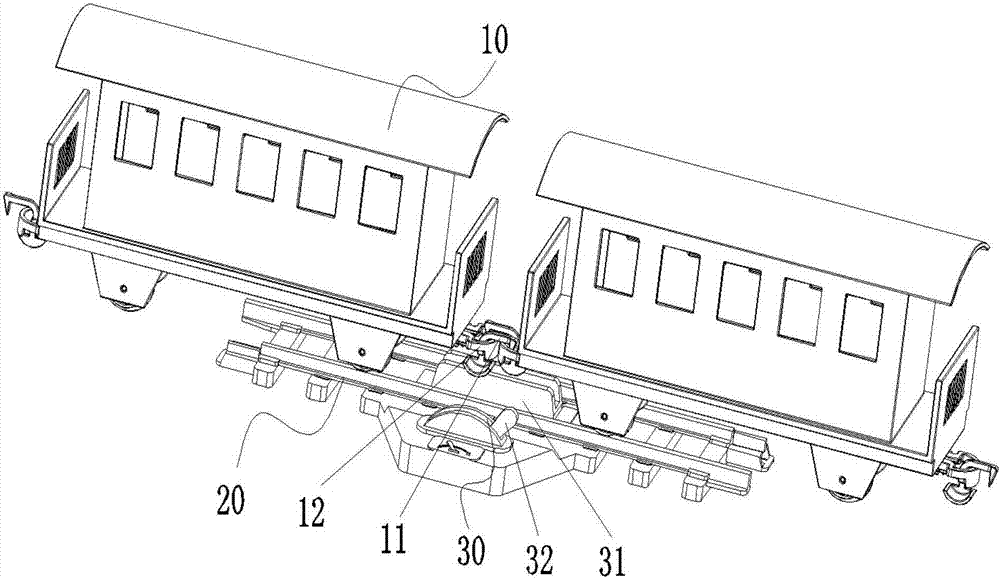

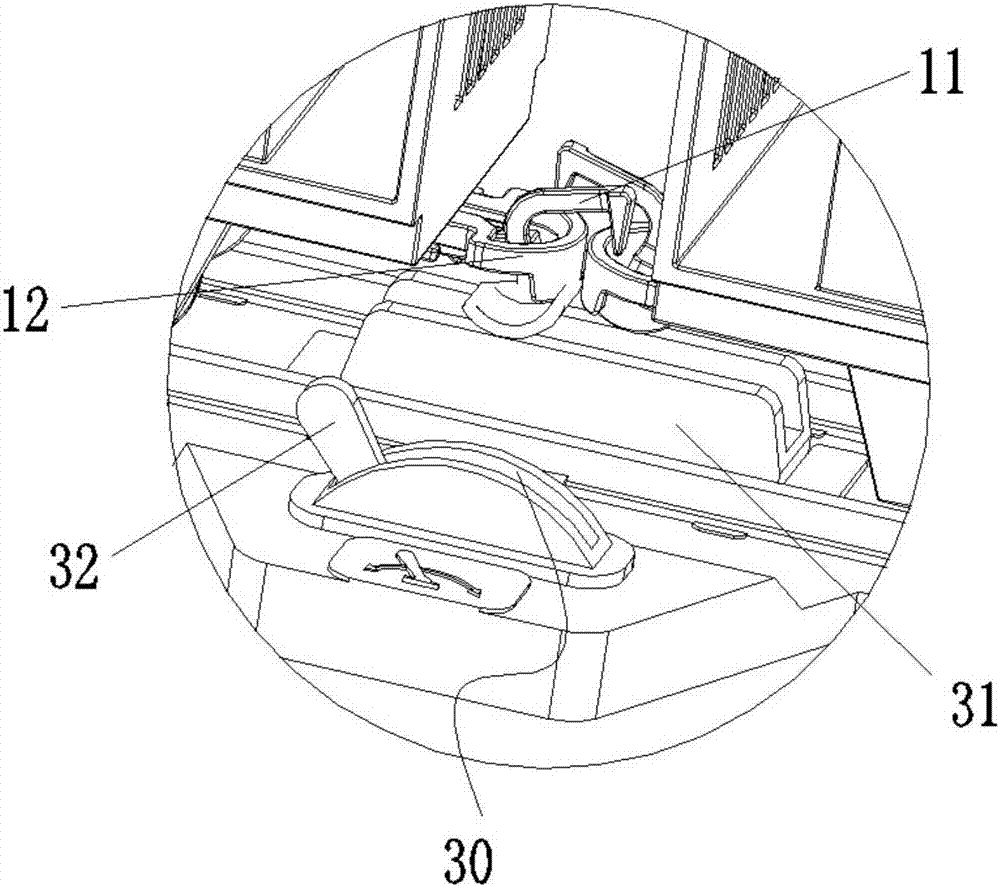

[0027] See Figure 1-Figure 7 . figure 1 It is a schematic diagram of the carriage and carriage assembly mechanism. figure 2 It is a schematic diagram of two adjacent carriages assembled and connected. image 3 It is a schematic diagram of the structure of the carriage assembly mechanism. Figure 4 It is a schematic diagram of the structure of the brake lever mechanism and the reminder mechanism. Figure 5 It is a schematic diagram of the structure when the brake lever of the brake lever mechanism is dropped. Image 6 It is a schematic diagram of the structure of the auxiliary rail and the rail changing mechanism. Figure 7 It is a schematic diagram of the structure of the main rail changing to the straight auxiliary rail.

[0028] The toy train of the present invention includes a plurality of carriages 10, a main rail 20, a carriage assembly mechanism 30 and a brake lever mechanism 40. Each of the multiple carriages 10 is provided with a hook 11 and a hanging ring 12, and the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com