Switchgear operating mechanism-integrated gas box

An operating mechanism and switchgear technology, applied in contact operating mechanism, electric switch, contact driving mechanism, etc., can solve the problems of blocked movement of moving parts, mechanism failure, easy drying of grease, etc., to achieve work reliability, Ensure that the action is normal and the effect of eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

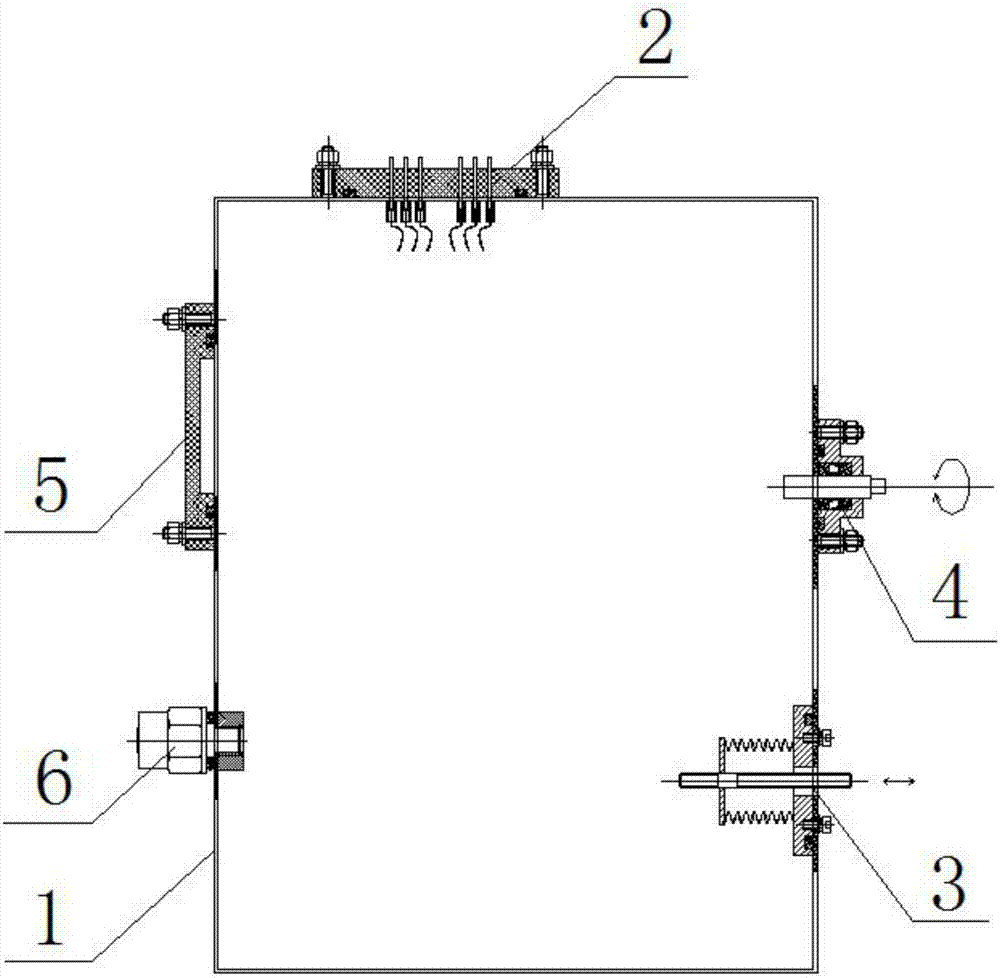

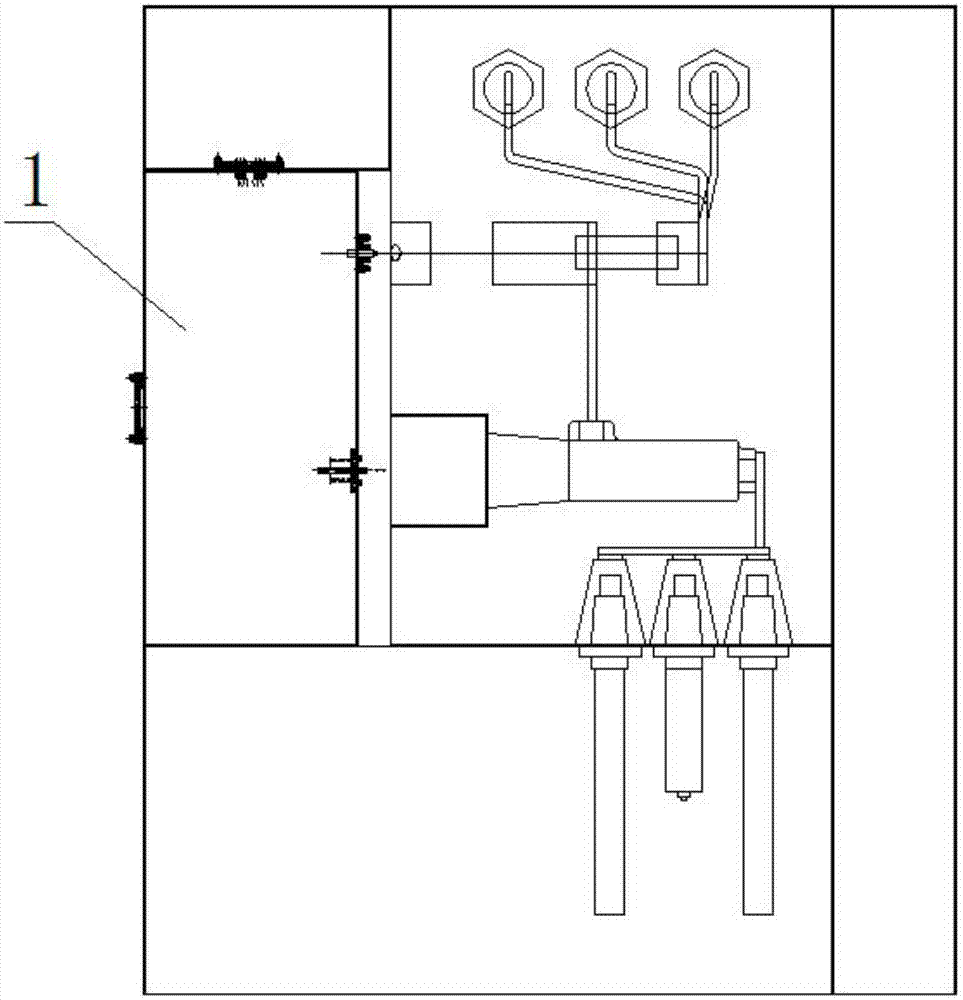

[0017] Such as Figure 1-2 As shown, a switchgear operating mechanism integrated gas box includes a gas box 1, a control line socket flange 2 is arranged on the top of the gas box 1, and a direct-acting interface flange 3 is arranged on the side wall of the gas box 1. The rotating interface flange 4, the observation window flange 5 and the air pipe seat 6 with a one-way valve; the direct-acting interface flange 3 and the rotating interface flange 4 are arranged on the back of the air box 1, and are distributed up and down; The observation window flange 5 and the air pipe seat 6 are arranged on the front of the air box 1, distributed up and down; a pressure gauge is installed on the air pipe seat to intuitively understand the air pressure change inside the air box 1.

[0018] Nitrogen or dry air is flushed into the gas box 1, and various flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com