A tubular water-cooling device for the lining of the whole pouring furnace roof

A technology of water cooling device and furnace roof, applied in the direction of furnace cooling device, etc., can solve the problems of complex, tearing and leaking installation of furnace lining cooling device, achieve the effect of simple material and manufacturing, avoid faults in manufacturing and installation, and ensure safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

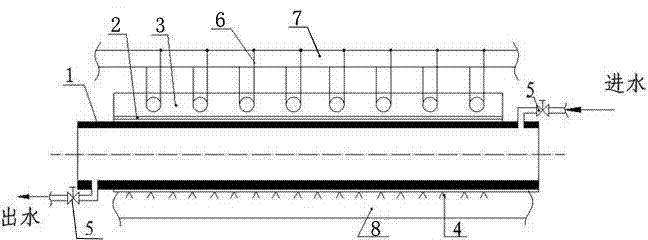

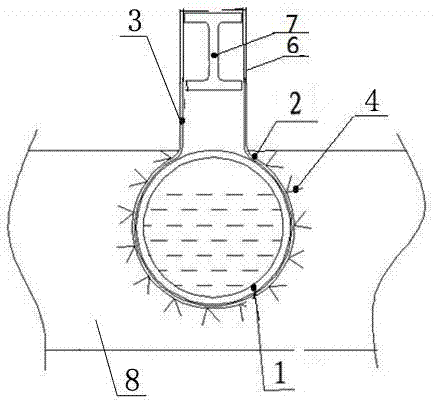

[0017] Such as figure 1 and figure 2 As shown, a tube-type water-cooling device for casting furnace roof lining is provided with a water-cooled tube 1 for cooling water circulation and an outer sleeve 2 wrapped outside the water-cooled tube 1, and the water-cooled tube 1 and The outer casing 2 is buried in the refractory lining 8 on the top of the casting furnace. The outer diameter of the water-cooled pipe 1 and the inner diameter of the outer casing 2 are set so that the water-cooled pipe 1 can slide and extend along the outer casing 2 when heated and expanded. Both ends protrude from the refractory lining 8, and the two ends of the water-cooled pipe 1 protruding from the refractory lining 8 are respectively equipped with valves for controlling water inlet and outlet; the upper side of the outer casing 2 is provided with an opening extending along its axial direction. The opening is exposed to the outside of the refractory lining 8, and the arc length of the opening on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com