Wafer clamping device for semiconductor packaging

A technology of semiconductors and clips, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of metal pin clamping is not firm, semiconductor integrated circuit damage, metal pins are easy to break, etc., to avoid metal pins The effect of pin breakage, breakage prevention, and excessive clamping force prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

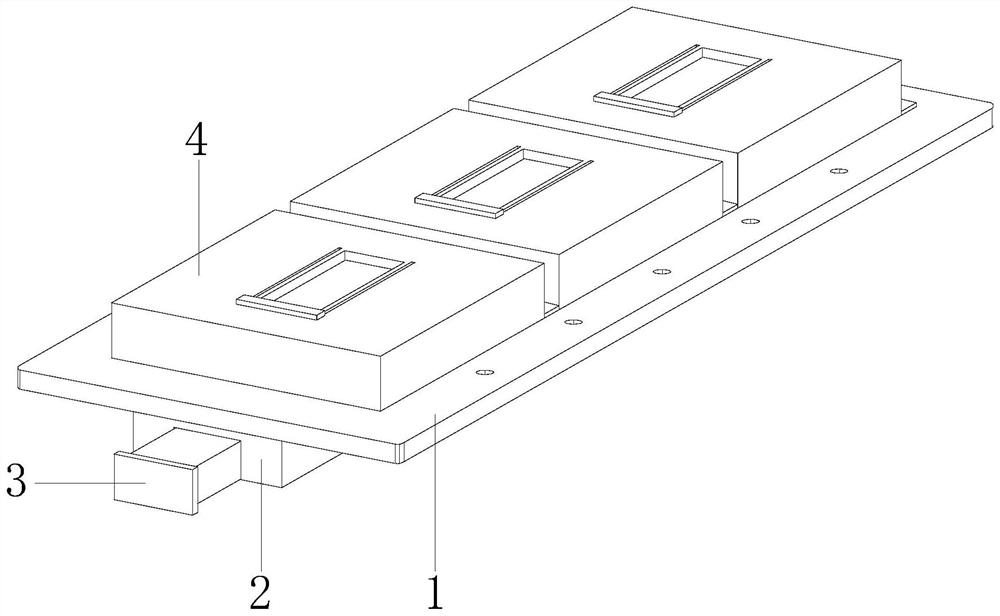

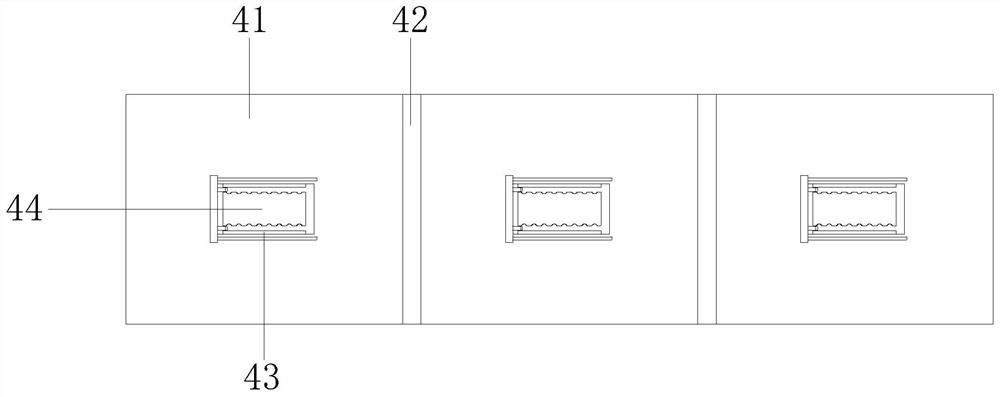

[0022] as attached figure 1 to attach Figure 5 Shown:

[0023] The present invention is a clipper for semiconductor packaging, its structure includes a mounting plate 1, a slide rail 2, a drive rod 3, and a clamping mechanism 4, the bottom of the mounting plate 1 is welded with a slide rail 2, and the drive rod 3 adopts clearance fit Through the inside of the slide rail 2, a clamping mechanism 4 is welded on the upper surface of the mounting plate 1, and the clamping mechanism 4 includes a fixing groove 41, a slant plate 42, a side clamping mechanism 43, and an inner support mechanism 44. The fixing groove The bottom of 41 is fixedly welded on the upper surface of the mounting plate 1, and the inclined plate 42 is arranged at the lower end of the right side of the fixing groove 41, and the side clamping mechanism 43 is installed inside the fixing groove 41, and the side clamping mechanism 43 is located outside the inner support mechanism 44, so There are three fixing groove...

Embodiment 2

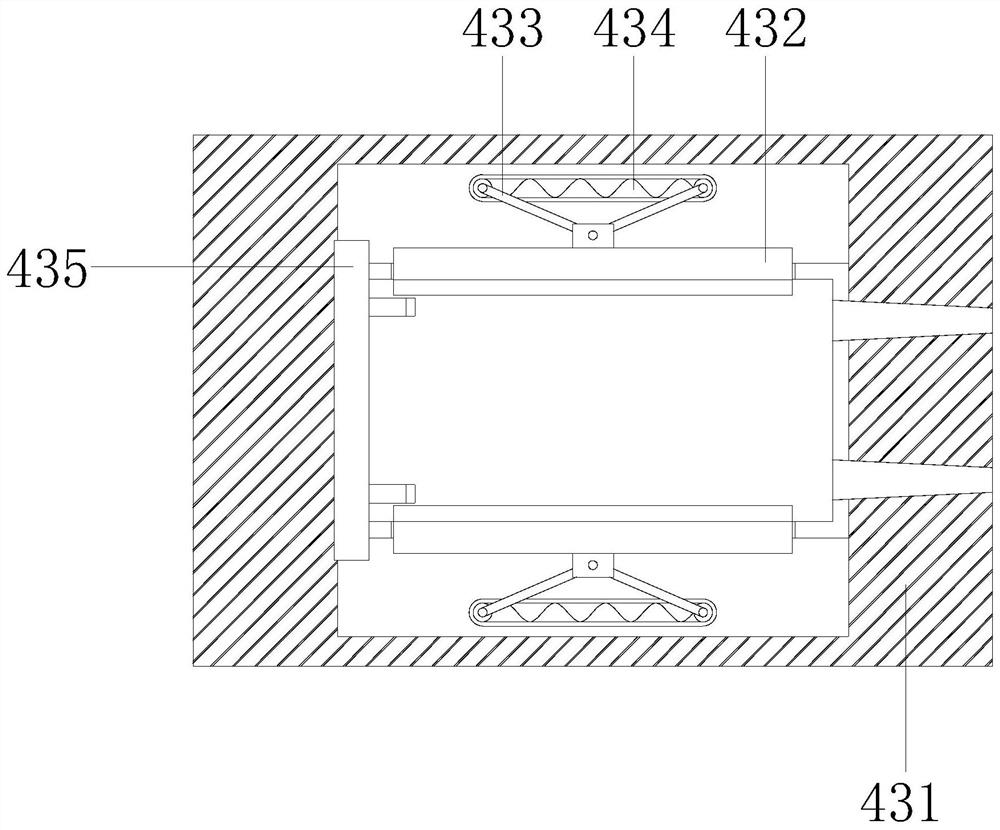

[0030] as attached Figure 6 to attach Figure 7 Shown:

[0031] Wherein, the inner support mechanism 44 includes a support plate 44a, an extrusion plate 44b, and an engaging mechanism 44c. The lower end of the support plate 44a is fixedly installed on the inner bottom surface of the fixing seat 431, and the upper end surface of the support plate 44a is embedded with an extrusion plate. 44b, and the extrusion plate 44b is connected to the inner middle end of the engaging mechanism 44c, the engaging mechanism 44c is arranged on the outside of the support plate 44a, the cross section of the support plate 44a is rectangular, and matches the shape of the integrated circuit, It is beneficial to place the bottom surface of the integrated circuit on the upper surface of the support plate 44a. There are two engaging mechanisms 44c, which are respectively arranged on the front and rear surfaces of the support plate 44a, which is beneficial to the two rows of parallel metal pins of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com