Stirring dry-type mechanical sealing device for kettle

A mechanical sealing device, dry technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problem of easy leakage of radial seals, and achieve the effect suitable for popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

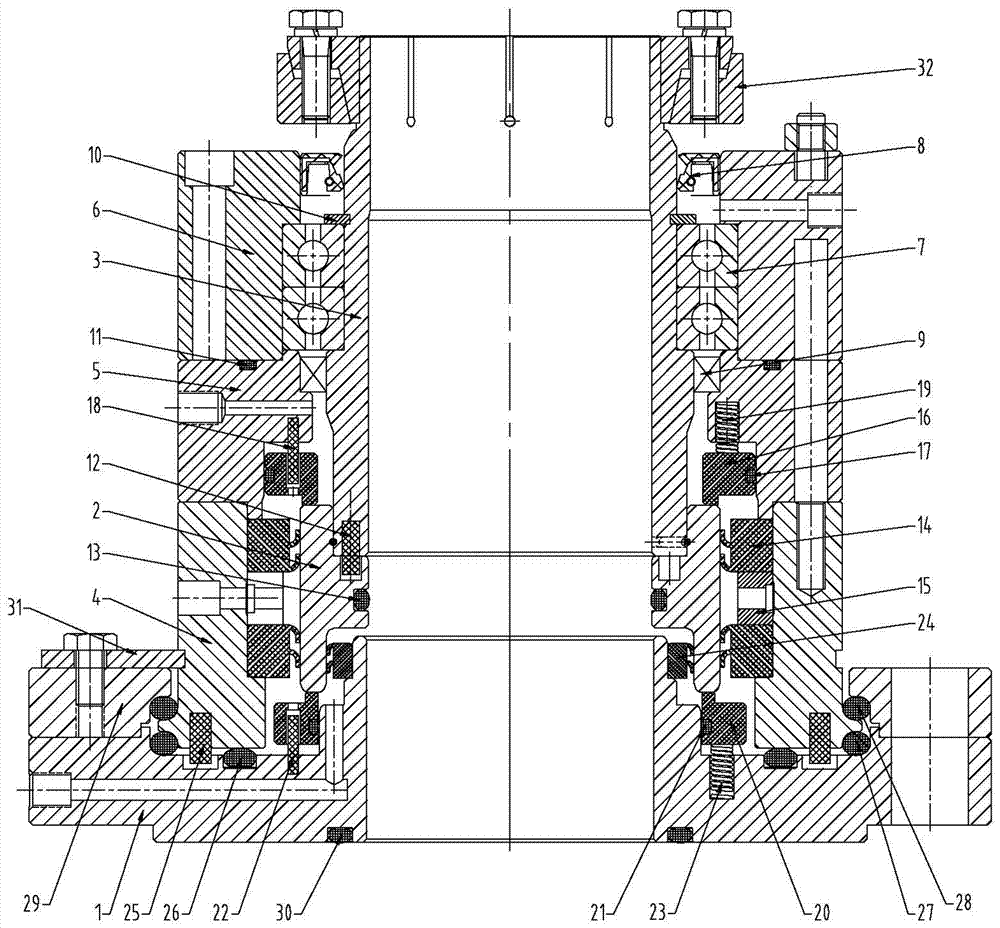

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Such as figure 1 Shown: a stirred dry mechanical seal device for a kettle, including a bottom flange 1, a moving ring sleeve 2, a shaft sleeve 3, a seal seat body 4 and an upper static ring seat 5, a bottom flange 1, a moving ring sleeve 2 and The shaft sleeve 3 is arranged from bottom to top and the inner walls of the three are set close to the stirring shaft. The main body of the seal seat 4 and the upper static ring seat 5 are located above the bottom flange 1 and outside the moving ring sleeve 2 and the shaft sleeve 3. The shaft The top of the sleeve 3 is provided with a locking mechanism 32, and the locking mechanism 32 is fixed on the top of the shaft sleeve 3 by bolts and washers. A bearing seat 6 is provided above the upper static ring seat 5, and a first O-shaped rubber sealing ring 11 is provided at the contact surface position between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com