flat knitting machine

A technology of flat knitting machines and needle beds, which is applied in the field of knitting machinery, and can solve problems such as the inability to adjust the gap between the needle beds, the restriction of the knitting effect of the flat knitting machine, and the inability to meet the knitting requirements, and achieve good adjustment effects, simple structure, and satisfactory adjustment. required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

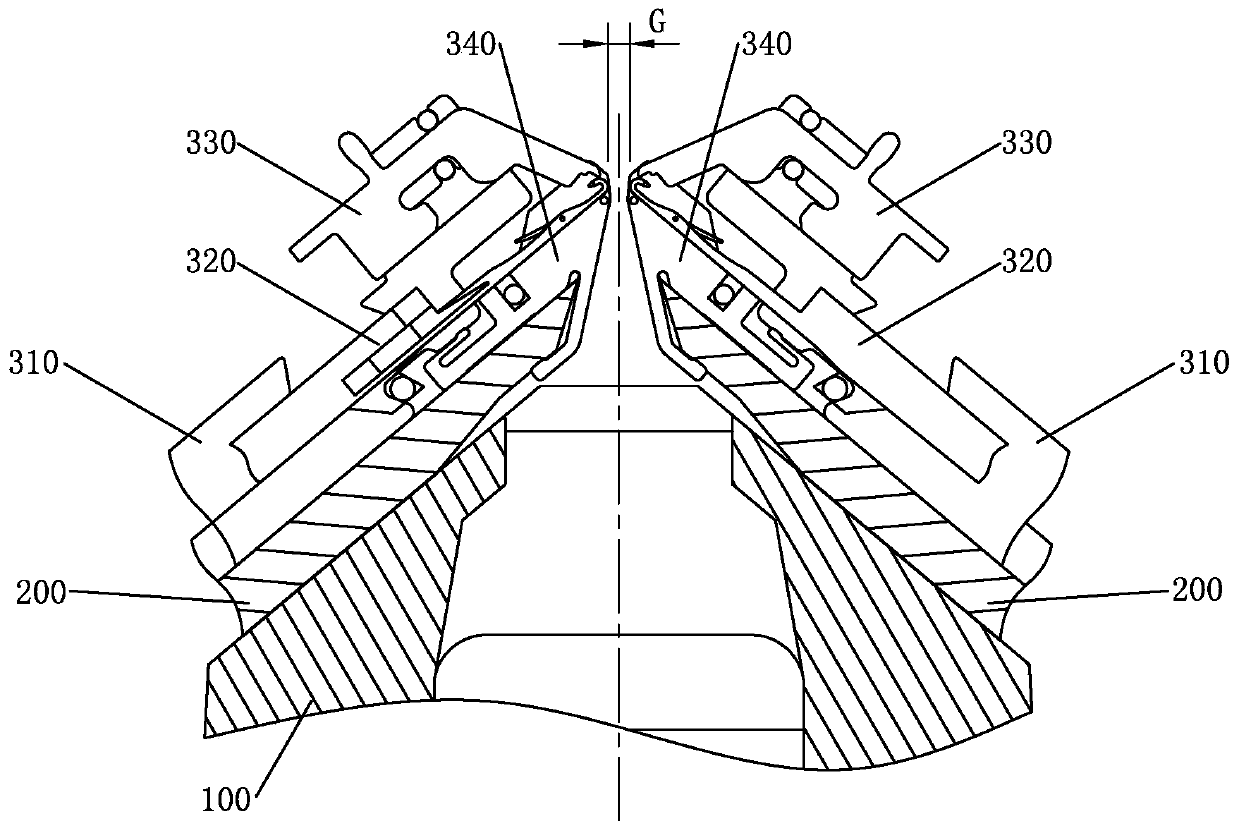

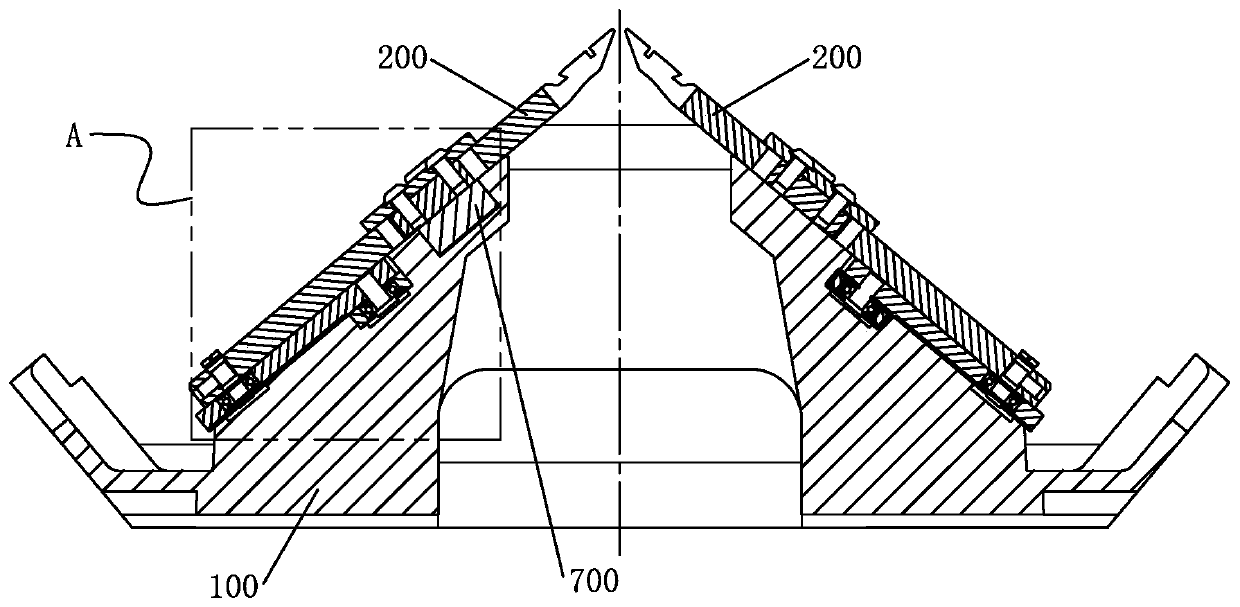

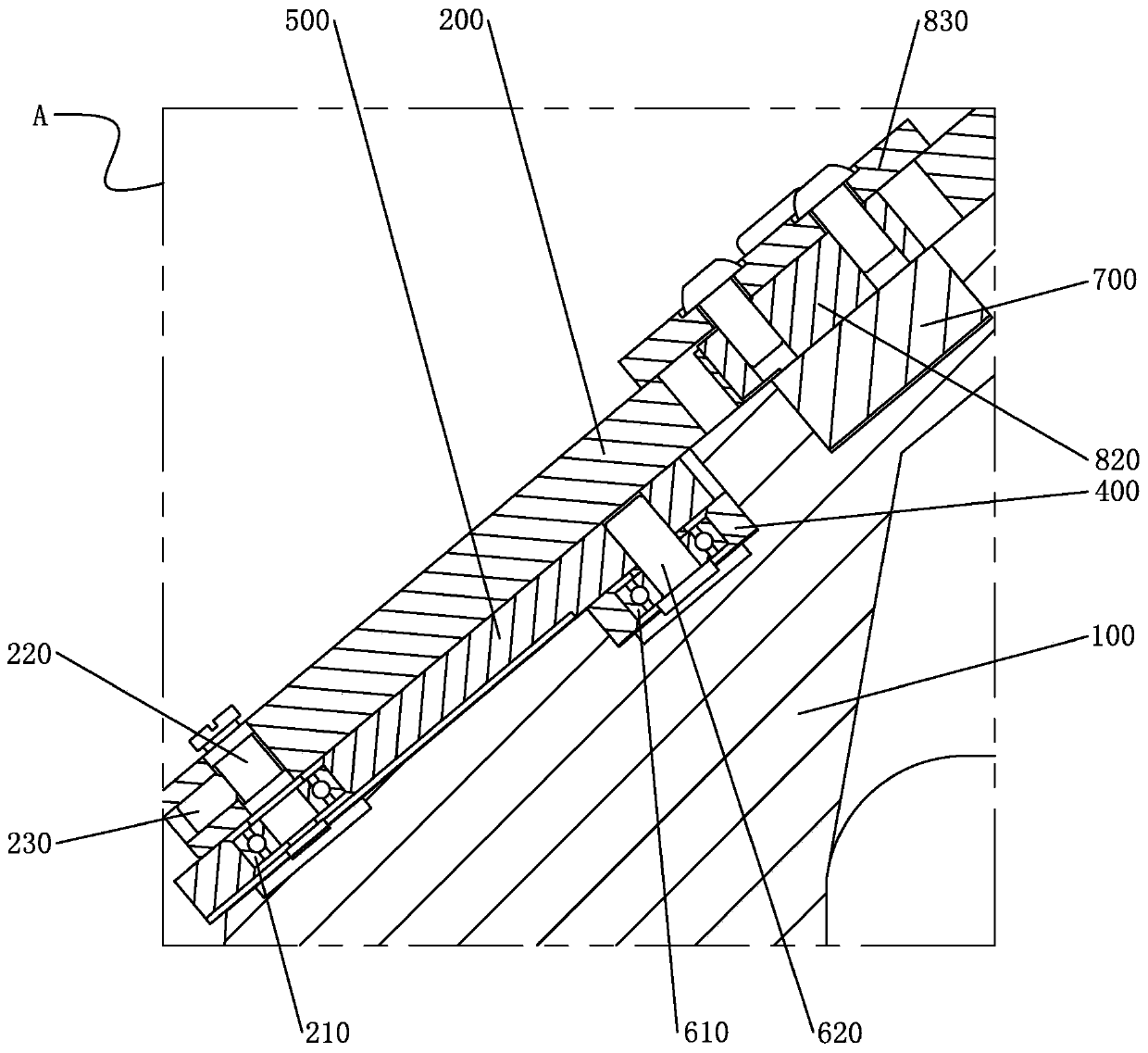

[0039] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the flat knitting machine provided by Embodiment 1 of the present invention includes a needle bed base 100 and a needle bed 200. The needle bed base 100 is provided with two symmetrically inclined base surfaces 101, and the needle bed 200 is provided with two And be arranged on two base surfaces 101 respectively, on the front of needle bed 200, be provided with a plurality of inserting pieces 310 side by side at intervals, the front side of needle bed 200 is provided with tooth mouth plate 340 that is positioned at the front end of inserting piece 310, two needle beds A gap G between the tooth mouth pieces 340 on the 200 is provided. The flat knitting machine also includes an adjustment mechanism for adjusting the gap G of the needle bed plate mouth. The adjustment mechanism includes a horizontal adjustment piece, an oblique adjustment piece and a linkage piece. The horizontal adjustment piece is arranged on ...

Embodiment 2

[0059] like Figure 7As shown, Embodiment 2 of the present invention is an equivalent embodiment of the above-mentioned Embodiment 1. The difference between it and the above-mentioned Embodiment 1 is that the adjustment surface 402 is an inclined surface directly arranged on the transverse inner wall of the through groove 401, that is, it is arranged obliquely. A certain angle is set between the adjusting surface 402 of the sliding rail 400 and the length direction of the sliding rail 400 . This structure is beneficial to realize the stepless adjustment of the gap G of the needle bed, that is, the specific size of the gap G of the needle bed can be any value within the adjustment range, so as to better meet the adjustment requirements of the gap of the needle bed.

[0060] Specifically in this embodiment, since the left side of the adjustment surface 402 is higher, when the slide rail 400 moves laterally to the right, the adjustment plate 500 drives the needle bed 200 to rise ...

Embodiment 3

[0064] combine Figure 5 , Figure 8 Embodiment 3 of the present invention is an improved embodiment of the above-mentioned first embodiment, and its improvement relative to the above-mentioned first embodiment is that the positioning shaft 220 includes a first shaft section 221 and a second shaft section 222 whose axis centers are staggered, The first shaft section is rotatably inserted into the through hole 201 , the end surface of the first shaft section is provided with a "one"-shaped slot, and the support wheel 210 is rotatably sleeved on the second shaft section.

[0065] In order to fix the positioning shaft 220 , the needle bed 200 is also provided with a positioning hole 202 perpendicular to the through hole 201 , and a positioning pin 230 for fixing the positioning shaft 220 is provided in the positioning hole.

[0066] When the needle bed 200 is installed on the needle bed base 100, the specific position of the needle bed relative to the needle bed base can be effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com