Exhaust baffle mechanism with accurately-adjustable opening degree for sintering furnace

A technology of exhaust baffle and sintering furnace, which is applied to furnaces, furnace types, furnace components, etc., can solve the problems of excessive exhaust gas, reduced pressure of sintering furnace, and inability to control exhaust gas discharge, and achieve precise control of exhaust volume. , The effect of precisely adjustable opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

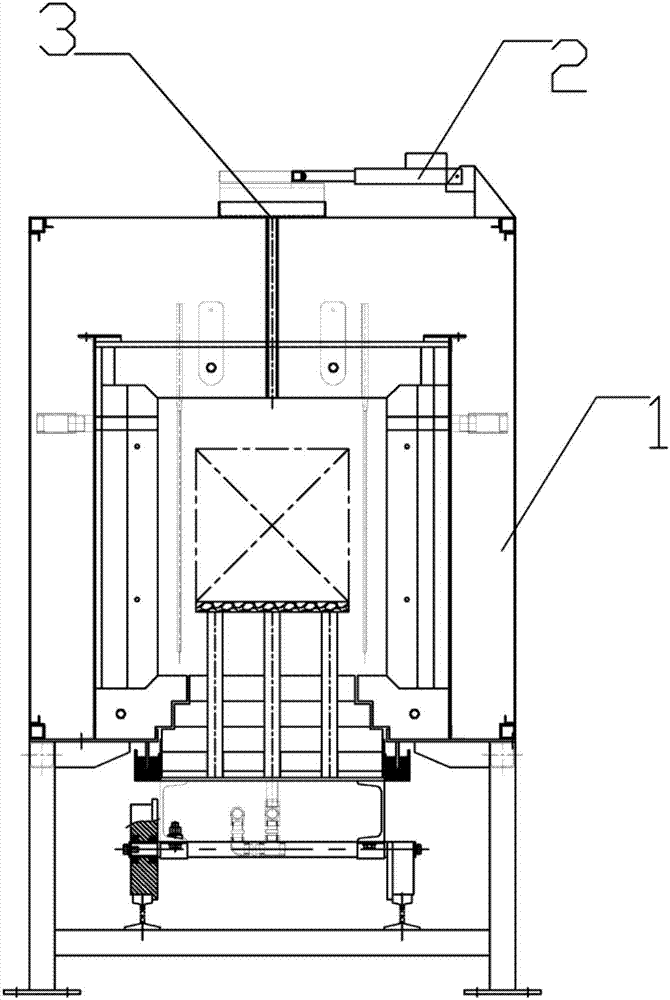

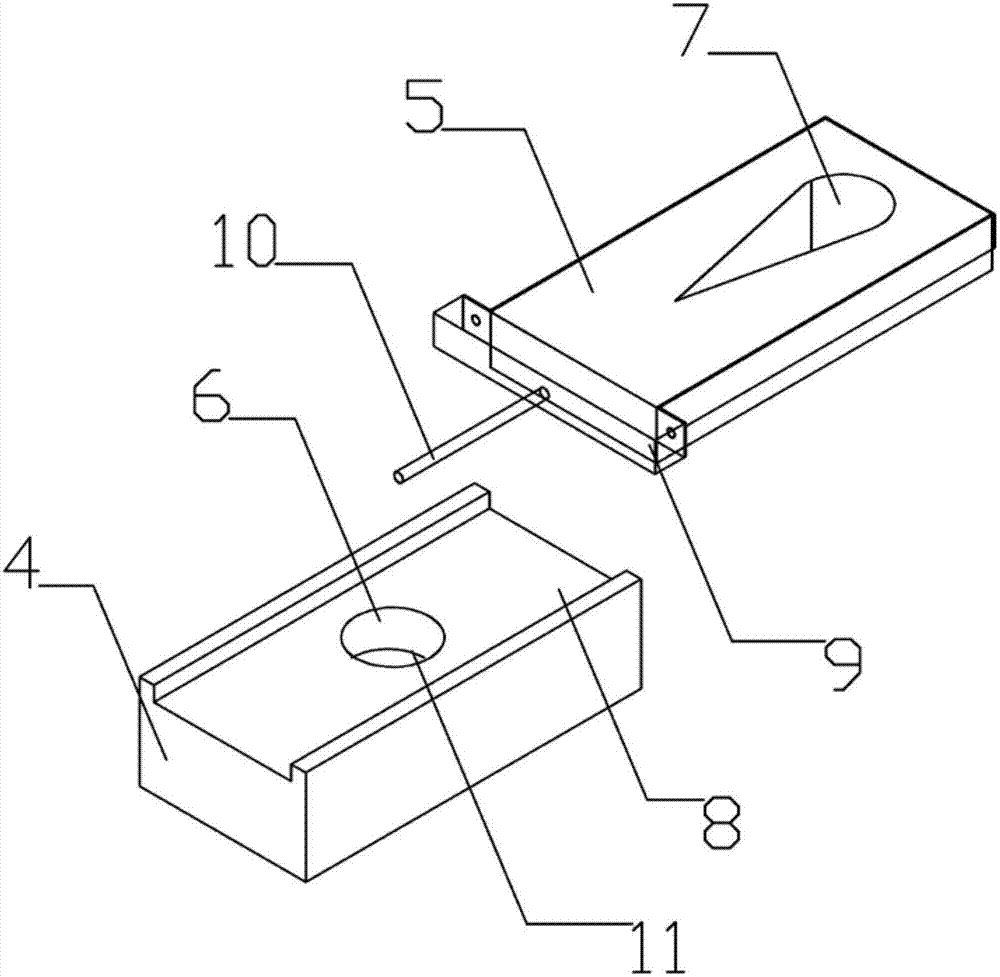

[0024] Example 1: Combination figure 1 versus figure 2 A sintering furnace exhaust baffle mechanism 2 with an accurately adjustable opening is shown, which is fixed on the top of the sintering furnace 1 and has a base 4 and a baffle 5, and the base 4 is provided with a row on the top of the sintering furnace 1. The air hole 3 communicates with the through hole 6.

[0025] The core design of the present invention is as follows: the baffle 5 is attached to the surface of the base 4, and the baffle 5 is provided with an adjusting hole 7 that matches the through hole 6 on the base 4. The movement of the plate 5 changes the opening of the through gap with the through hole 6.

[0026] A fixed frame 9 is provided on the baffle 5, and a pull rod 10 is provided on the fixed frame 9. In this embodiment, the baffle 5 is driven by an electric cylinder (not shown in the figure) connected to the pull rod 10 to perform a translational movement on the surface of the base 4. The surface of the b...

Embodiment 2

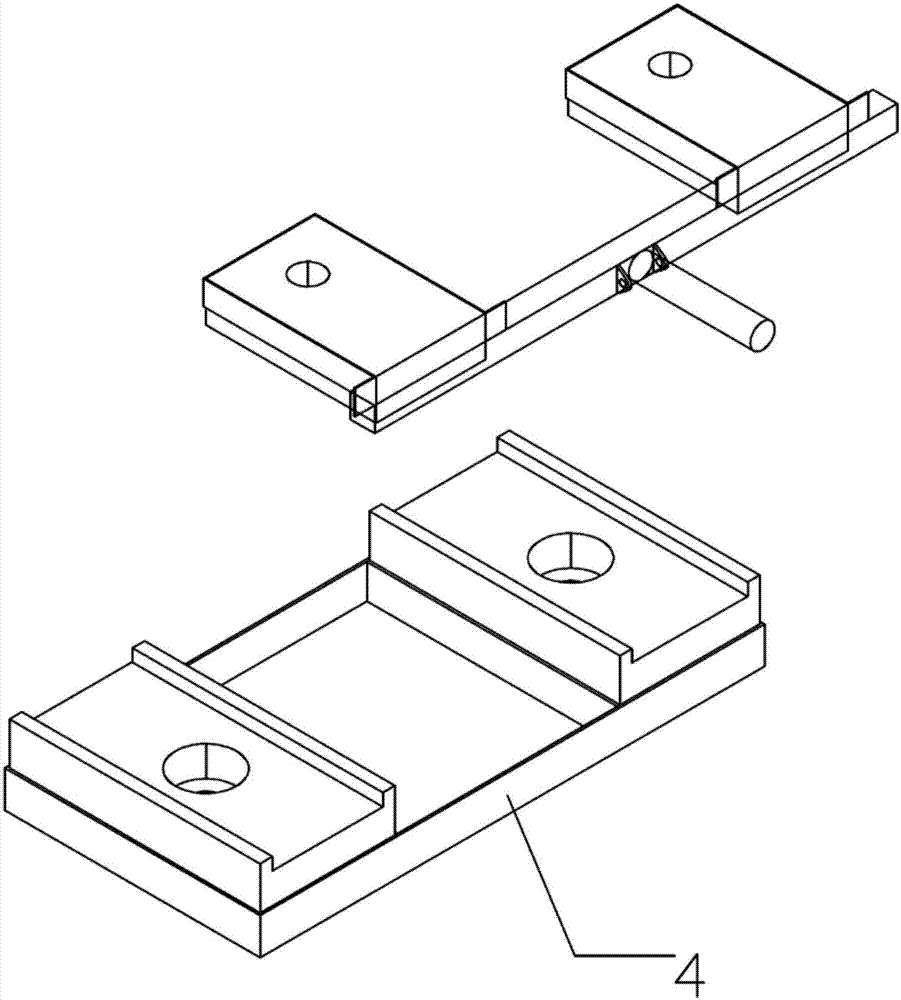

[0029] Example 2: Such as image 3 The difference between the exhaust baffle mechanism of the sintering furnace shown in Embodiment 1 is that: in this embodiment, there are two through holes 6 on the base 4, and the number of baffles 5 is the same as that of the through holes 6. Correspondingly, there are also two pieces, and the two baffles 5 are fixed on the same fixed frame 9. The center of the fixed frame 9 is connected with a tie rod 10, which is connected to an electric cylinder (not shown in the figure) and is driven by the electric cylinder The two baffles 5 move back and forth synchronously. In addition, the through hole 6 on the base 4 in this embodiment is a conventional round hole. The rest of the design of this embodiment is the same as that of embodiment 1.

Embodiment 3

[0030] Embodiment 3: This embodiment does not give drawings. The difference from Embodiment 1 is that the path groove is an arc-shaped groove, the baffle is provided with a fixed frame, the base is provided with a rotating shaft, and the The rotating shaft and the fixed frame are connected by a connecting piece, and the driving mechanism includes a motor. The output shaft of the motor is connected with the rotating shaft by a gear pair transmission. Therefore, when the motor is started, the output shaft drives the rotating shaft to rotate synchronously, and The rotating shaft drives the baffle to swing back and forth along the arc-shaped groove by the connecting piece, thereby realizing the adjustment of the matching opening between the adjusting hole on the baffle and the through hole on the base. The other design of this embodiment is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com