A kind of alcohol-hydrogen engine throttle valve and alcohol-hydrogen engine with dual structure

A throttle and engine technology, applied in the direction of engine components, combustion engines, engine control, etc., can solve the problems of long axial dimension, frequent switching, temperature fluctuation of cracking chamber, etc., and achieve small axial dimension, stable structure and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The invention provides an alcohol-hydrogen engine throttle valve with a double structure, which aims to precisely control the temperature of the gas entering the cracker, and accurately adjust the exhaust volume entering the cracking heating chamber through the throttle valve, so as to control the internal temperature of the cracking chamber the goal of.

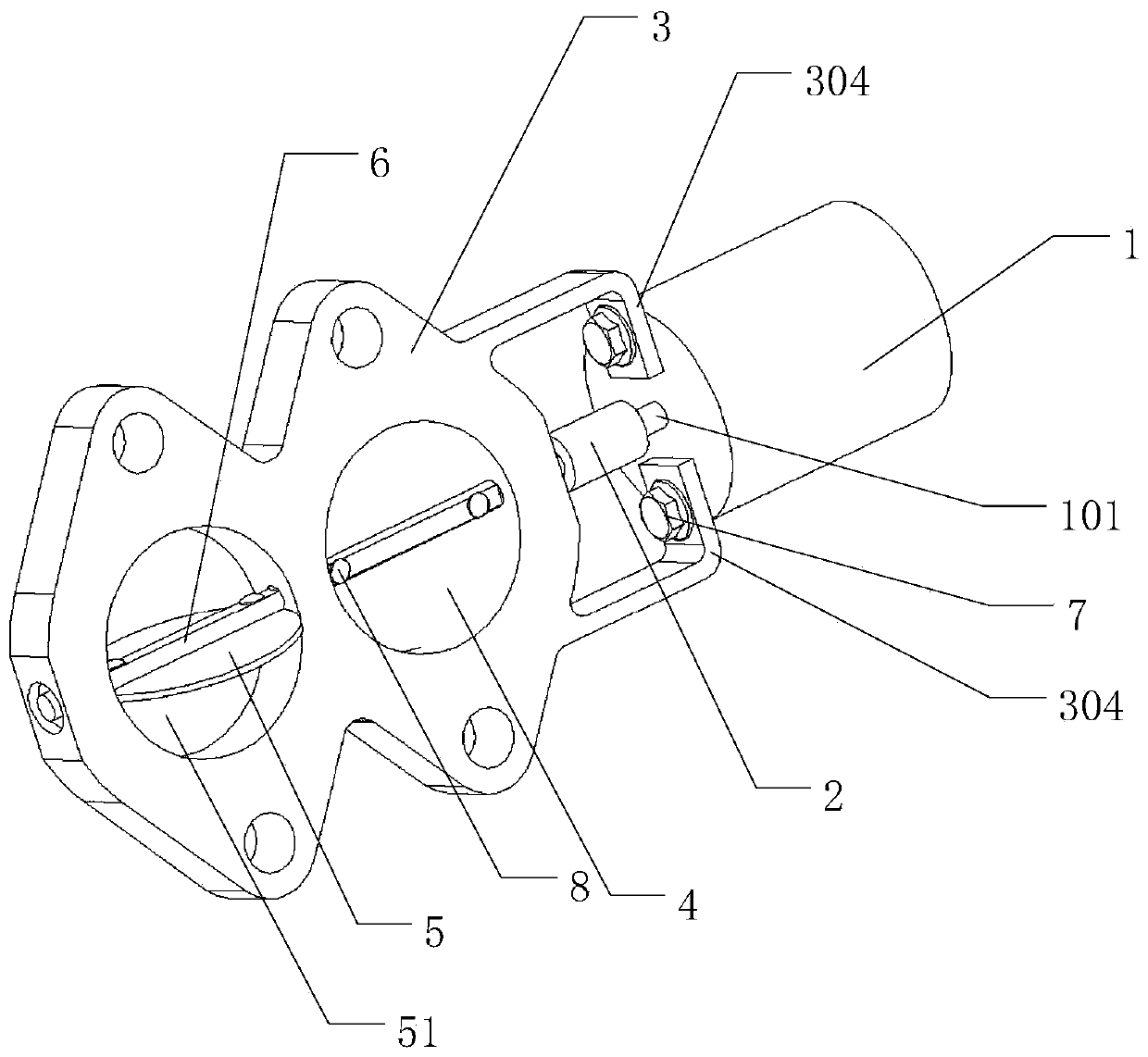

[0040] like figure 1 As shown, the present invention provides a kind of alcohol-hydrogen engine throttle valve with double structure, including: motor 1, coupling 2, double throttle base 3, first exhaust valve disc 4, second row Valve disc 5 and throttle shaft 6.

[0041] The motor 1 is fixed on the dual throttle base 3 .

[0042] Motor 1, also called electric motor, commonly known as motor, refers to an electromagnetic device that realizes the conversion or transmission of electric energy according to the law of electromagnetic induction. The main function of the motor 1 is to generate driving torque. As a power s...

Embodiment 2

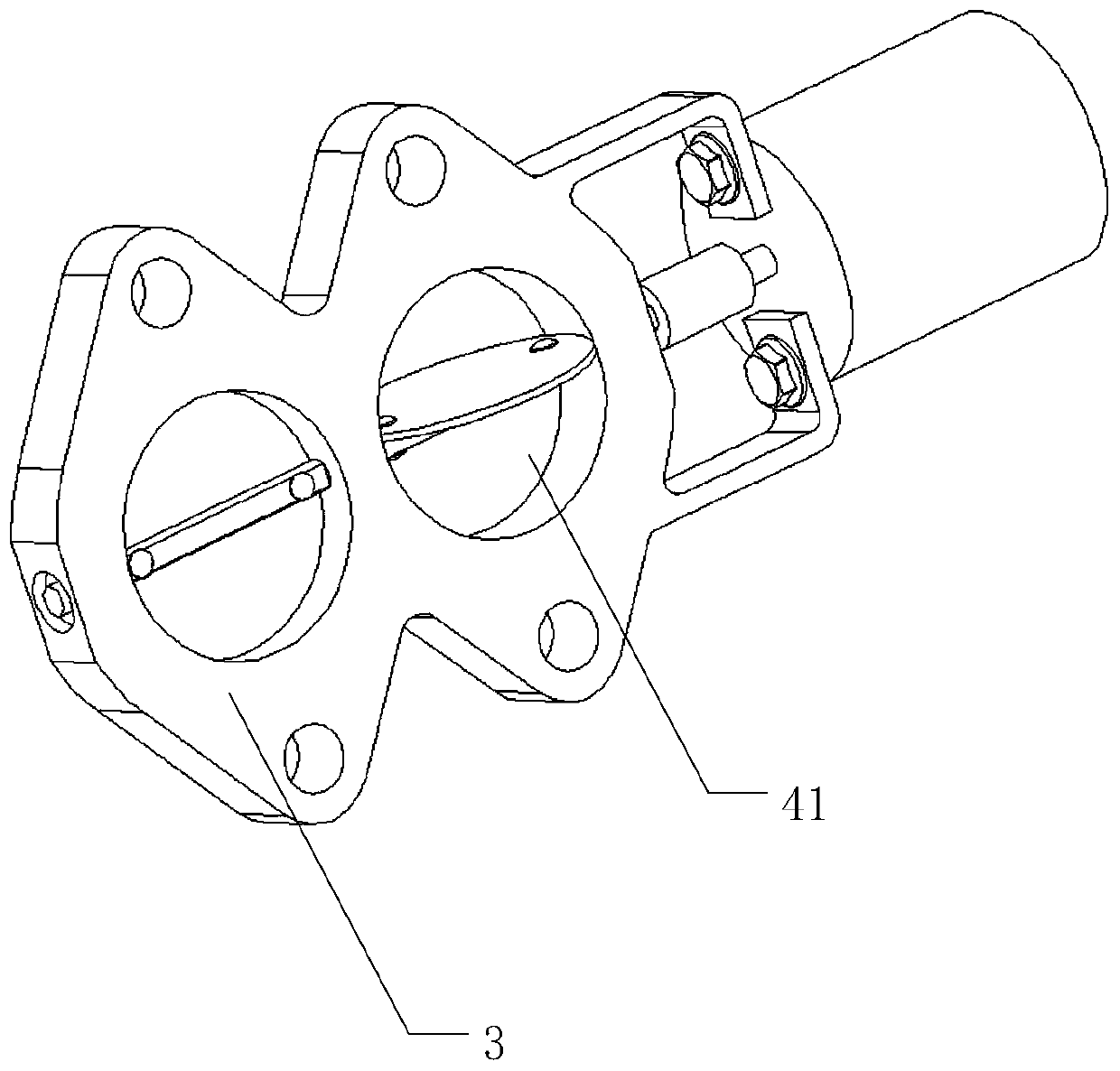

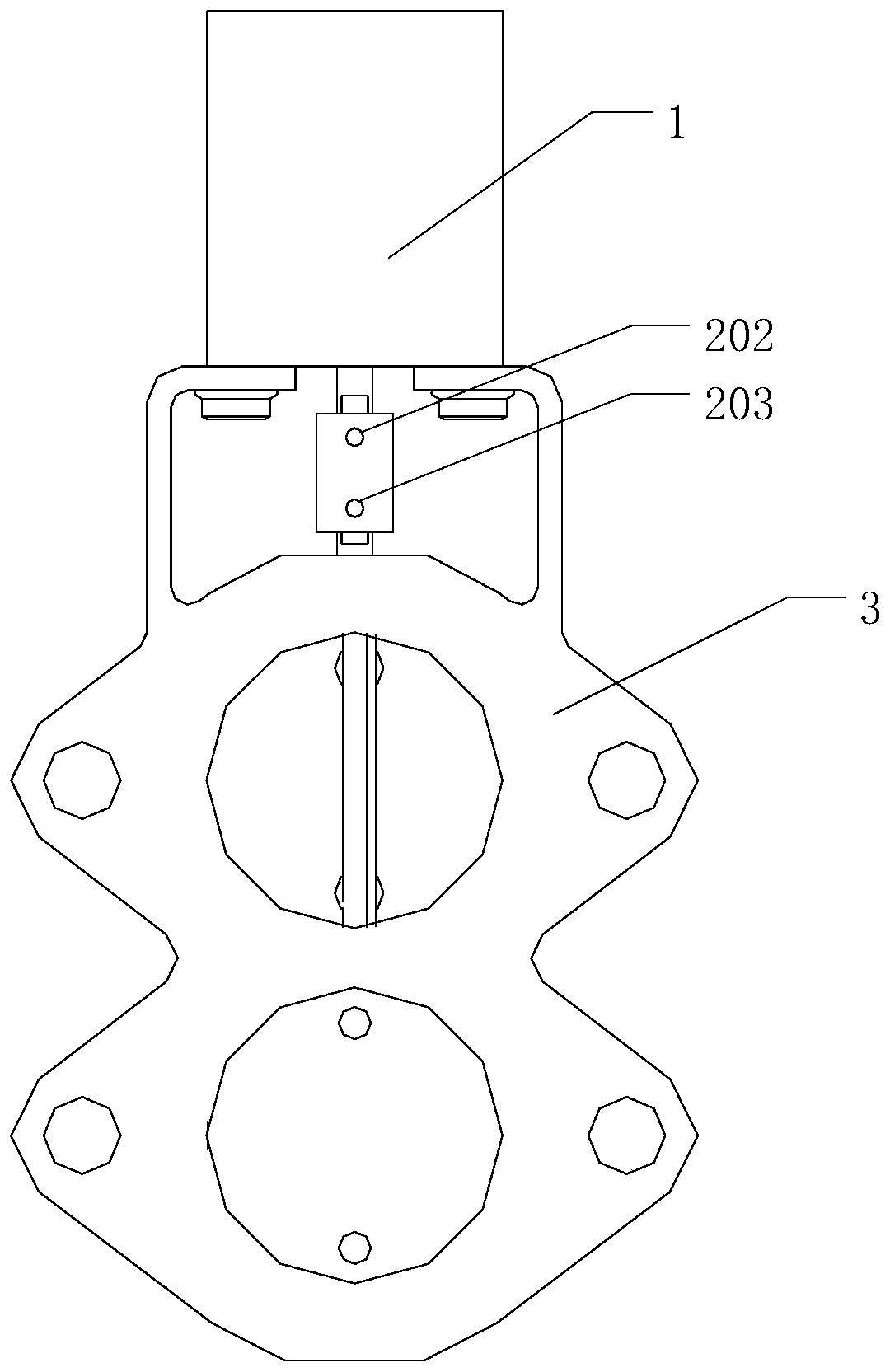

[0053] figure 1 Shown is the schematic diagram of the three-dimensional structure of the alcohol-hydrogen engine throttle with a double structure according to an embodiment of the present invention; the alcohol-hydrogen engine throttle with a double structure is in figure 1 The state in is the first exhaust valve closed state. figure 2 shown as figure 1 A schematic diagram of the first exhaust valve in an open state in the throttle valve of the hydrogen alcohol engine with a dual structure in the illustrated embodiment. image 3 shown as figure 1 The front view of the hydrogen alcohol engine throttle valve with a dual structure in the shown embodiment in the closed state of the first exhaust valve disc; Figure 4 shown as image 3 Rear view of the hydrogen alcohol engine throttle of the illustrated embodiment having a dual configuration. The following combination Figure 1 to Figure 4 The throttle valve of the alcohol-hydrogen engine with a dual structure according to t...

Embodiment 3

[0084] An embodiment of the present invention provides an alcohol-hydrogen engine, including the alcohol-hydrogen engine throttle valve with a double structure described in the first and second embodiments, and also includes a methanol cracker, an engine exhaust pipe and an exhaust bypass. The methanol cracker includes a cracking heating chamber and a cracking chamber, the first disc hole is used to communicate with the engine exhaust pipe and the cracking heating chamber, and the second disc hole is used to communicate with the engine exhaust pipe and the exhaust bypass. The cracking chamber cracks the methanol under the action of the catalyst by absorbing the heat of the cracking heating chamber.

[0085] The throttle valve of the alcohol-hydrogen engine with a double structure is set between the engine exhaust pipe and the pyrolysis heating chamber, the first disc hole corresponds to the air inlet of the pyrolysis heating chamber, and the second disc hole corresponds to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com