Energy-saving type refrigerating system and control method thereof

A refrigeration system and energy-saving technology, applied in the field of energy-saving refrigeration system and its control, can solve the problems of unstable operation of the system and frosting of the evaporator, achieve more accurate and stable temperature control, reduce the output of cold and heat, and avoid serious contamination. frost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

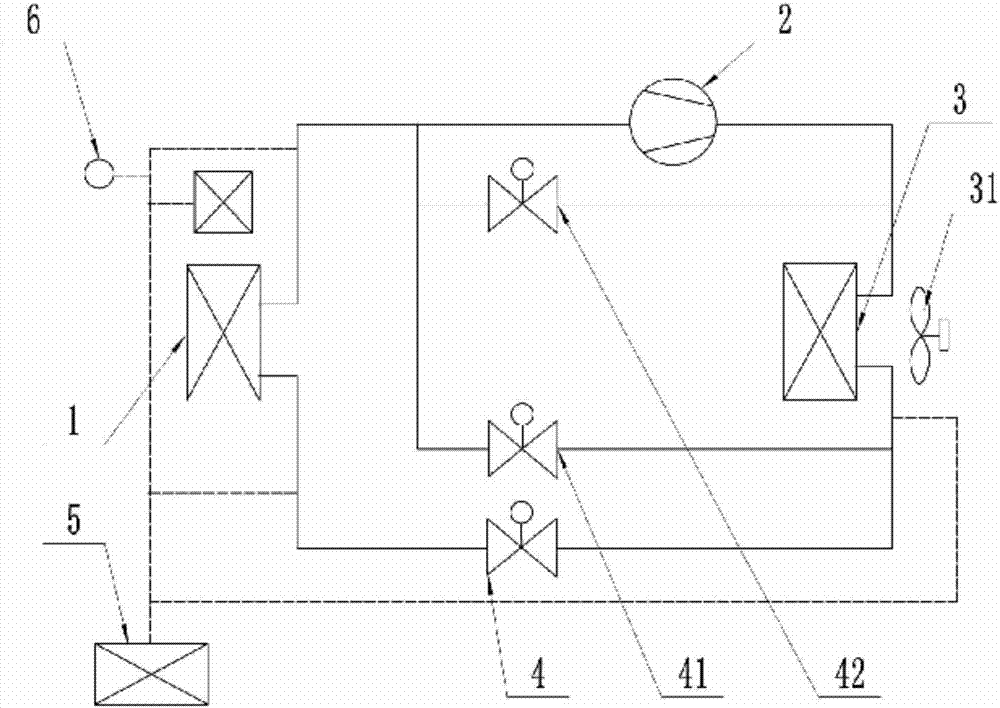

[0018] An energy-saving refrigeration system, comprising an evaporator 1, a compressor 2, a condenser 3, and an electronic expansion valve 4 in a refrigeration main circuit connected end-to-end through refrigerant pipelines; wherein, the evaporator 1 is used to evaporate cold amount to lower the space temperature; the compressor 2 plays the role of compressing the refrigerant, consumes electric energy, and generates cooling capacity; the condenser 3 is used to cool the high-temperature and high-pressure refrigerant.

[0019] The energy-saving refrigeration system also includes a control unit 5, an electronic expansion valve 41 of the refrigeration cold bypass circuit and an electronic expansion valve 42 of the refrigeration hot bypass circuit; the control unit 5 is respectively connected to the sensor group and the electronic expansion valve 4 of the refrigeration main circuit through wires , the electronic expansion valve 41 of the refrigerating and cold bypass circuit and the...

Embodiment 2

[0022] Described sensor group comprises refrigerating system sensor and temperature sensor 6 in the box, and described refrigerating system sensor comprises refrigerating system pressure sensor and refrigerating system temperature sensor, is used for measuring the pressure and temperature of refrigerating system; In a closed space for refrigeration, it is used to read the temperature inside the box at any time.

[0023] The control unit 5 includes a control chip and a storage device; the condenser 3 is provided with a cooling fan 31, and the cooling fan 31 generates wind speed to help the condenser dissipate heat.

[0024] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0026] A control method for an energy-saving refrigeration system, the steps of which include: the control unit 5 reads the temperature in the box and the pressure and temperature data of the refrigeration system through the sensor group, calculates the cooling capacity demand according to the temperature in the box, and then the control unit calculates The openings of the electronic expansion valve 4 of the refrigeration main circuit, the electronic expansion valve 41 of the refrigeration cold bypass circuit and the electronic expansion valve 42 of the refrigeration heat bypass circuit are controlled to adjust the cooling output of the refrigeration system and greatly reduce the Cooling and heating output to achieve energy saving; the reduction of cooling capacity can also avoid severe frosting of evaporator 1, so that the refrigeration system can run stably for a long time, and reduce the risk of liquid shock in the compressor.

[0027] The control method in embodiment 3 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com