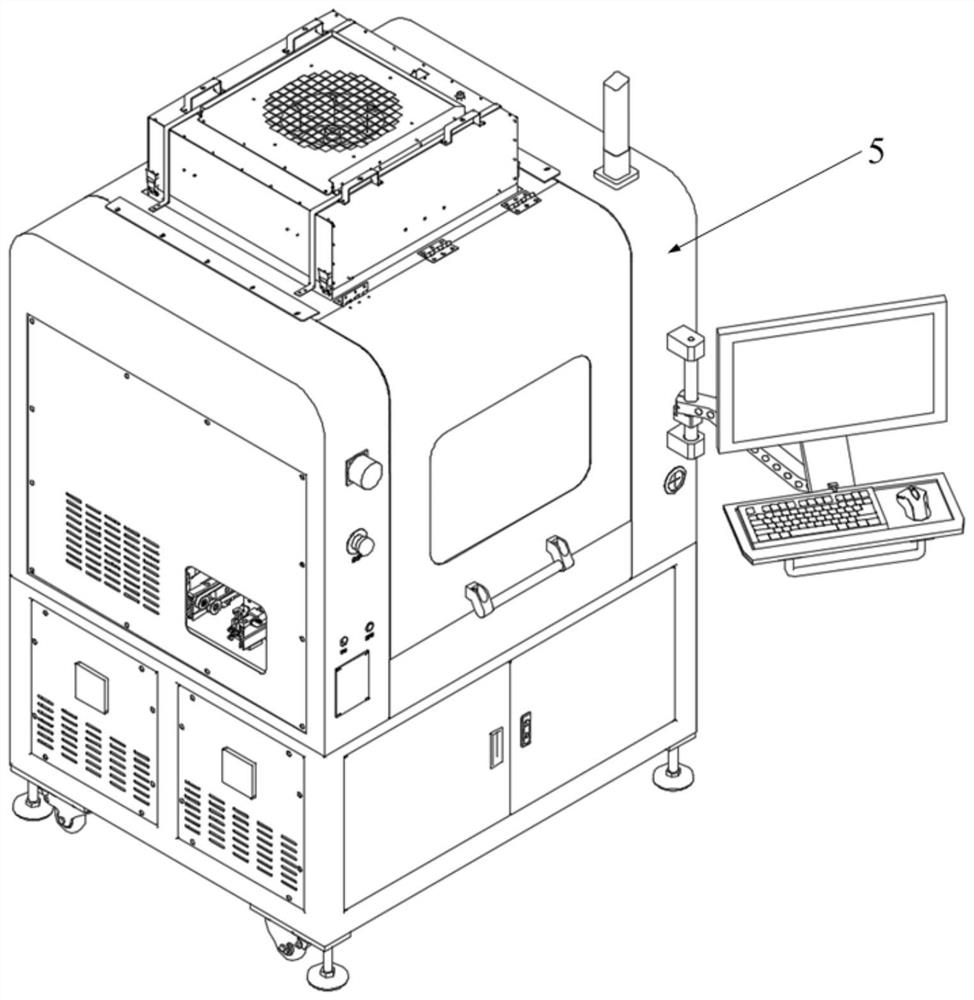

Full-automatic chip single-point tin removal equipment

A fully automatic, single-point technology, used in welding equipment, metal processing equipment, auxiliary devices, etc., can solve the problems of low tin removal efficiency, easily damaged chips, and high tin removal cost, so as to improve tin removal efficiency and avoid direct contact. , the effect of reducing the risk of damage to the chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

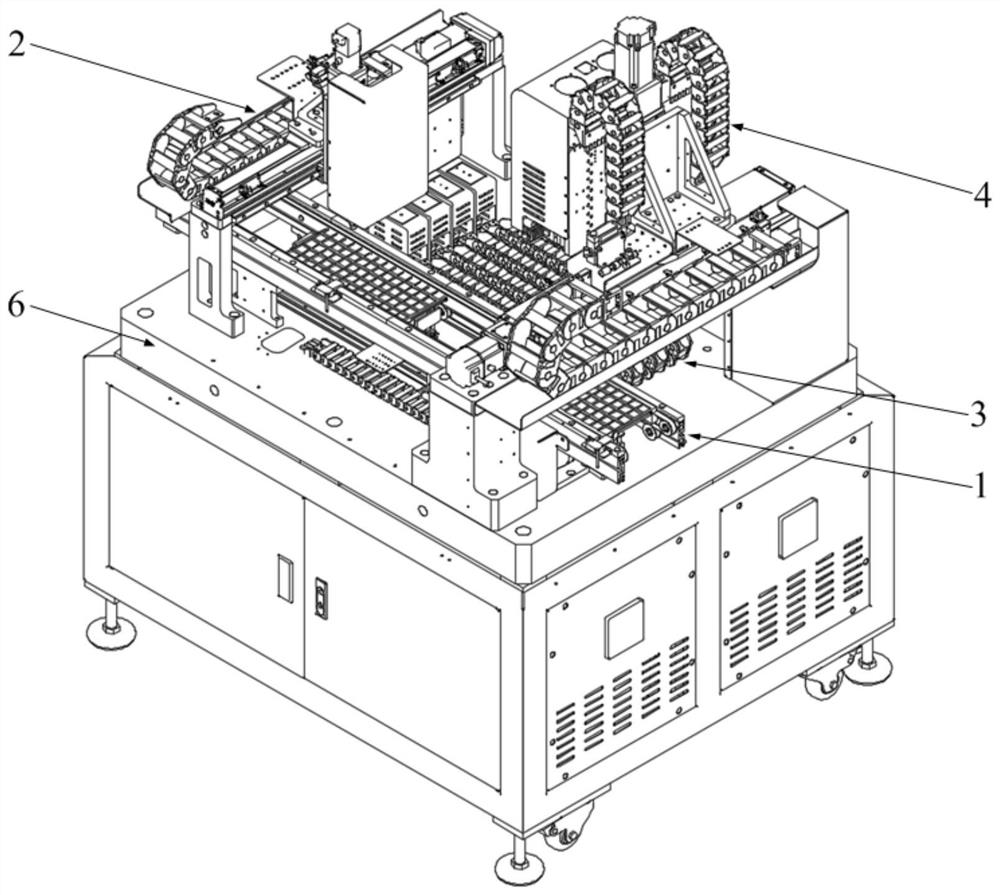

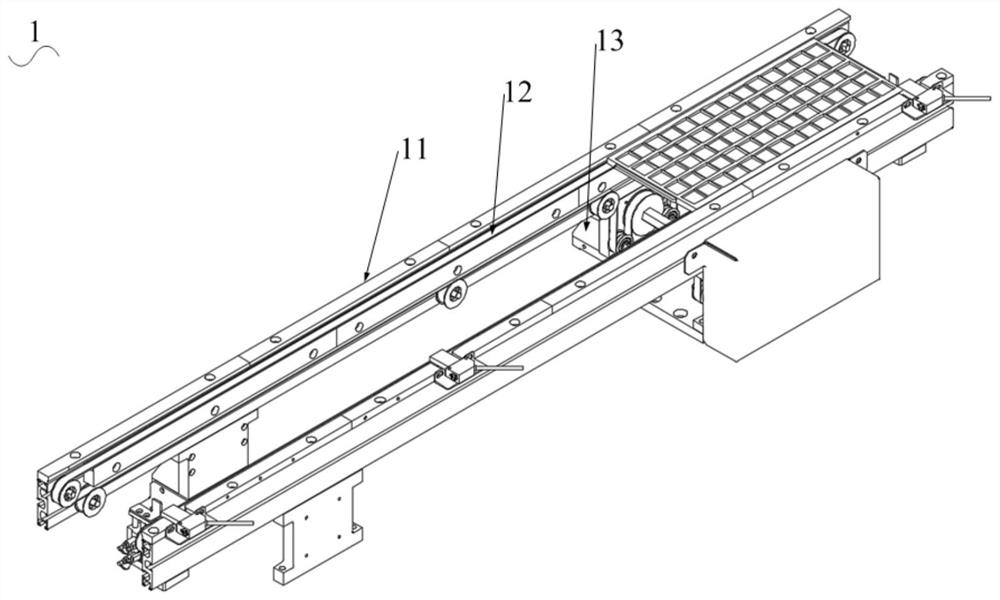

[0062] refer to Figures 1 to 11 As shown, the present invention provides a fully automatic chip single-point tin removal equipment, including a material transfer device 1, a material transfer device 2 arranged above one end of the vertical material transfer device 1, and a parallel material transfer device 1 arranged on one side thereof A number of preheating conveying devices 3, and a single-point tin removing device 4 arranged above the other end of the material conveying device 1; The material transfer device 2 is used to transfer the chip to the preheating transfer device 3; the preheating transfer device 3 is used to preheat the chip, and transfer the preheated chip to the single point tin removal device 4 Below: the single-point tin removal device 4 is used to remove tin from the chips, and the material transfer device 2 is also used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com