Synchronous rotation mechanism of galloping calibration device

A technology for synchronous rotation and calibration of devices, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to detect and calibrate the galloping monitor, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

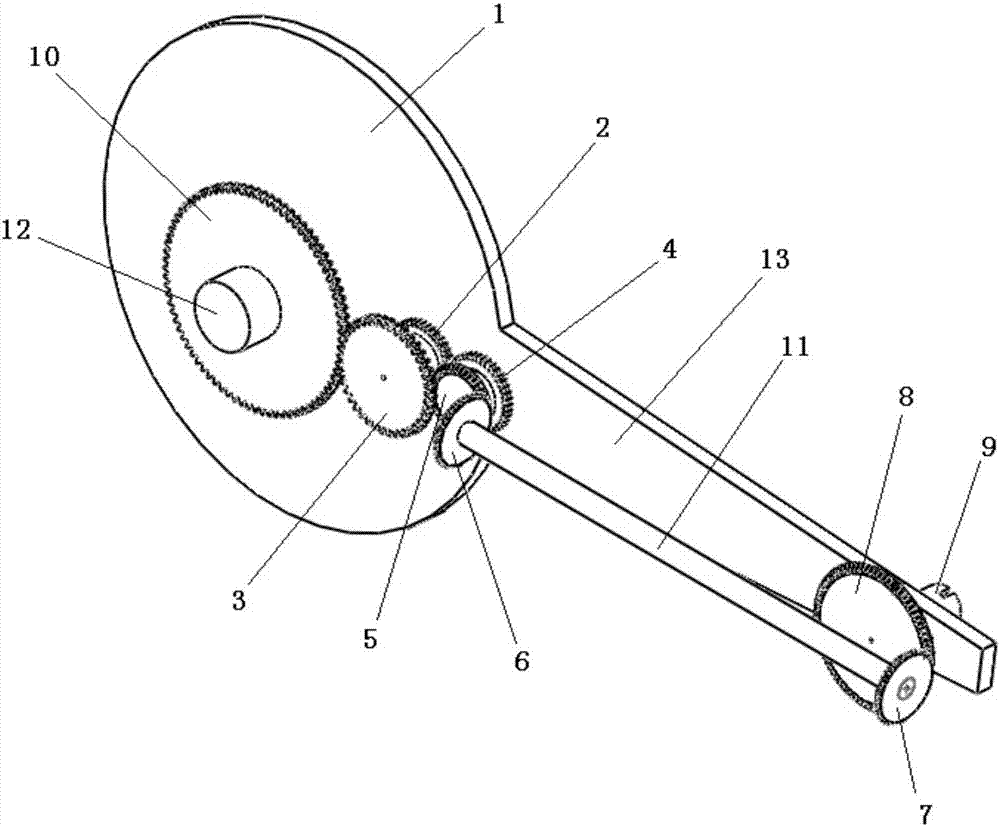

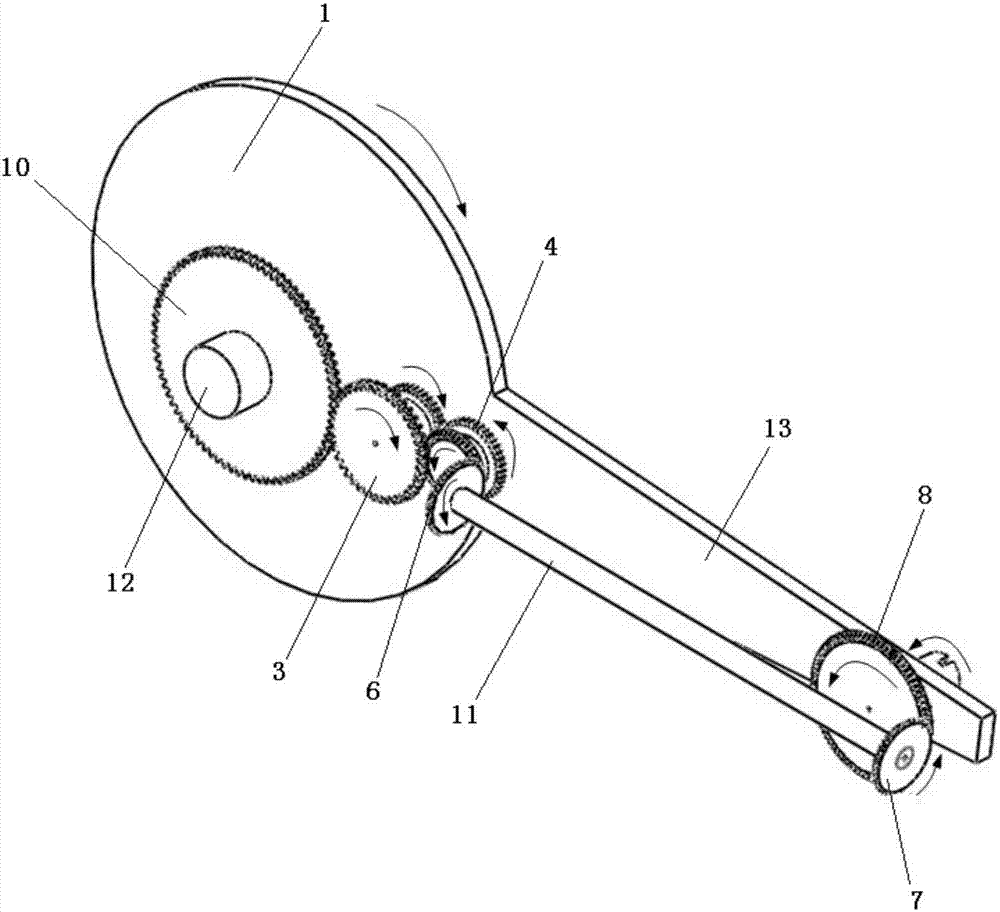

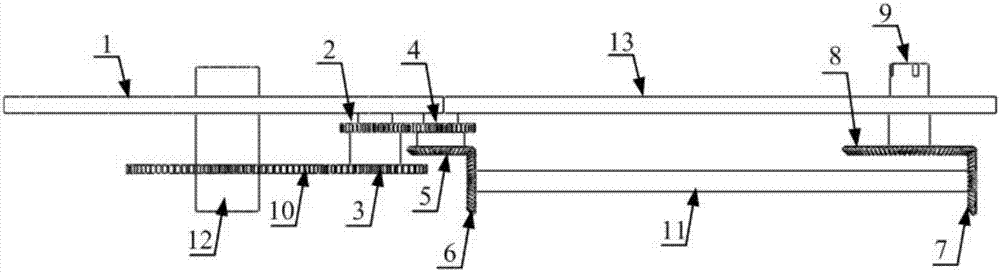

[0031] Such as figure 1 As shown, the present invention provides a synchronous rotation mechanism of a dancing calibration device, which includes a turntable 1, a central gear 10, an instrument mounting bracket 9, a bracket end gear 8 and a gear transmission. The synchronous rotating mechanism is set vertically when in use, that is, the turntable 1 rotates in a vertical plane, and the turntable 1 is generally in the shape of a disc, and can also be in other forms. In this embodiment, it is in the shape of a disc. The center of rotation of the turntable 1 is fixed with a drive shaft 12, the drive shaft 12 is connected to the motor and driven by the motor to rotate at a certain speed and direction, the turntable 1 is driven by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com