Diethyl ether anhydrous treatment apparatus

A water treatment device, ether technology, applied in the direction of ether preparation, ether separation/purification, etc., can solve the problems of complex combination and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

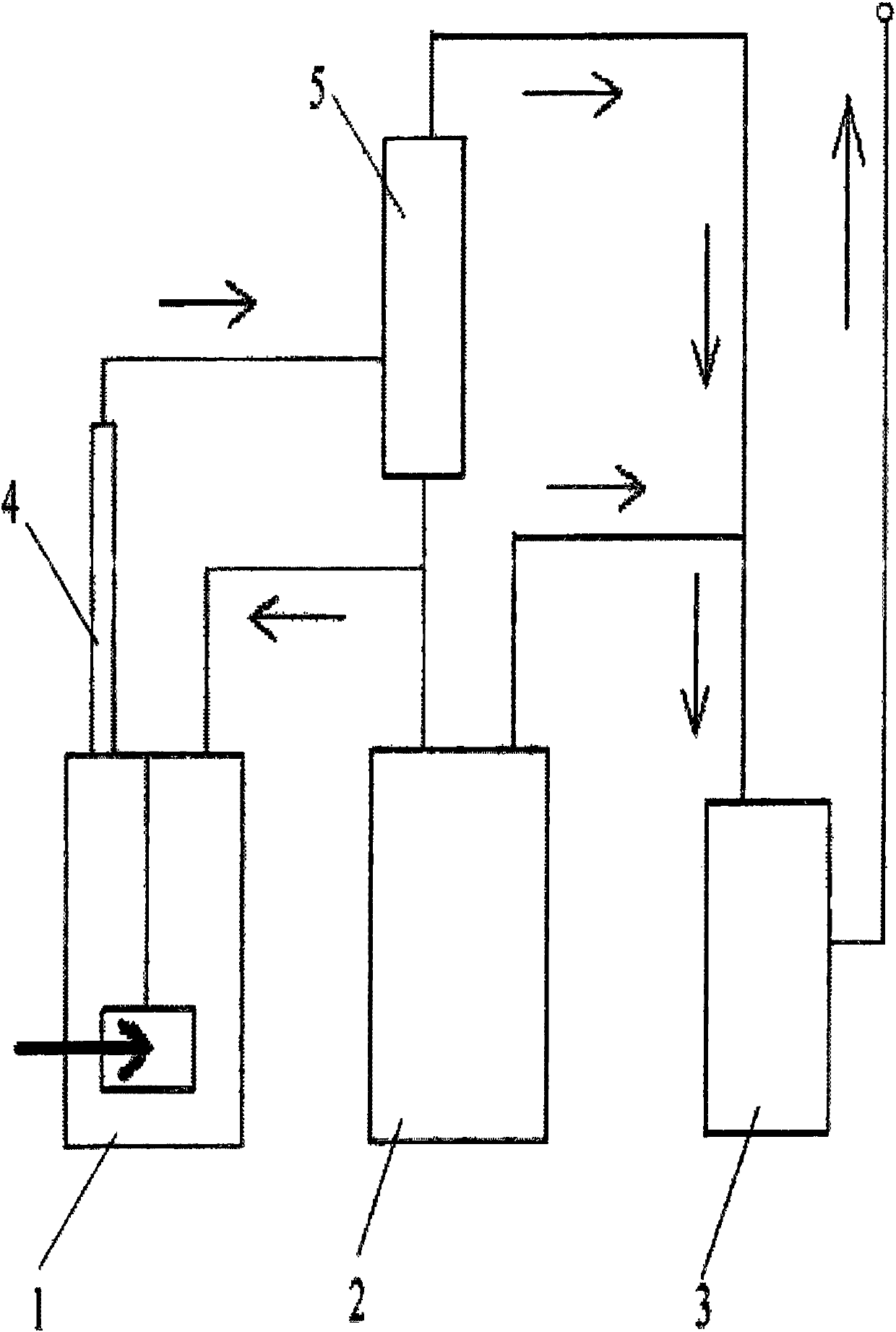

[0012] Such as figure 1 As shown, the ether anhydrous treatment device includes a raw material ether heating tank 1, a crude separation column 4, a calandria condenser 5, a refined ether receiving tank 2 and a tail gas absorption liquid sealing tank 3, and the raw material ether heating tank 1 is provided with The metal sodium hanging basket, the raw material ether heating tank 1 is connected with the crude effect separation column 4, the outlet of the coarse effect separation column 4 is connected with the inlet of the calandria condenser 5, and the outlet of the calandria condenser 5 is connected with the refined ether receiving tank 2, The tail gas outlet of the calandria condenser 5 and the tail gas outlet of the refined ether receiving tank 2 are also respectively connected to the tail gas absorption liquid sealing tank 3 .

[0013] The raw material ether is heated and refluxed in the raw material ether heating tank 1 to fully react with the added metal sodium to reduce t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com