Mine returning dredging device and method for blast furnace cloth bag pneumatic ash conveying pipeline

A technology for pneumatic ash conveying and ash conveying pipeline, applied in the field of metallurgy, can solve the problems of easy ash blocking and high labor intensity of ash conveying pipeline, and achieve the effect of solving ash blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

[0027] Aiming at the aforementioned problems that the existing blast furnace gas bag dust removal and pneumatic ash conveying pipeline is prone to clogged ash, and the labor intensity of cleaning the ash conveying pipeline is high, the present invention proposes a device and method for dredging the return of the blast furnace bag pneumatic ash conveying pipeline, thereby Solve the problem that the blast furnace gas bag dust removal pneumatic ash conveying pipeline is prone to clogging.

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

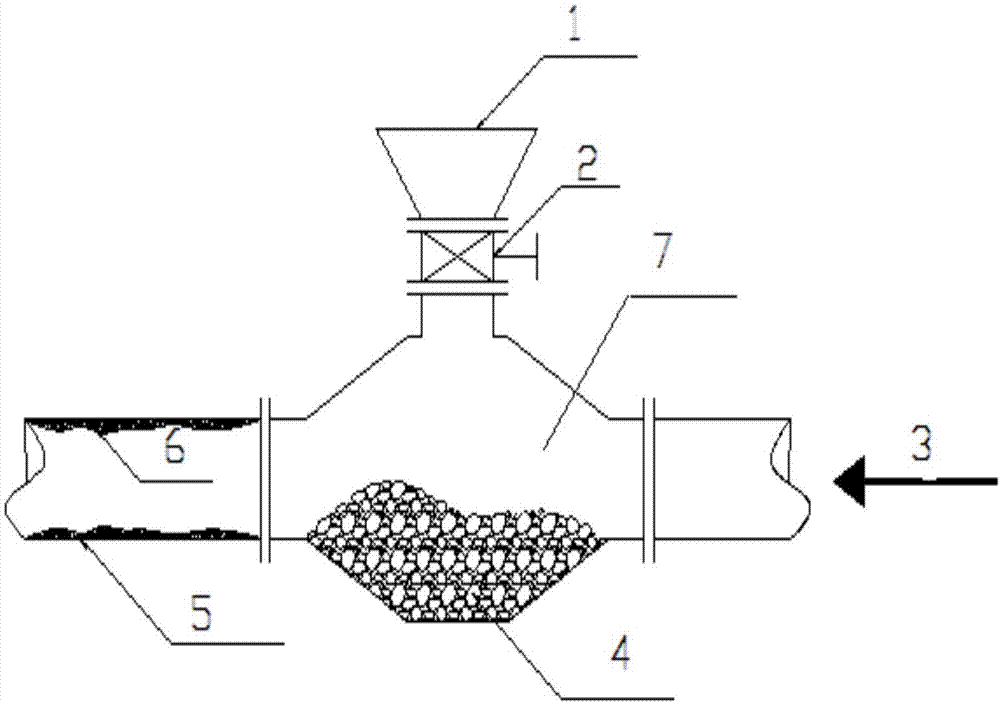

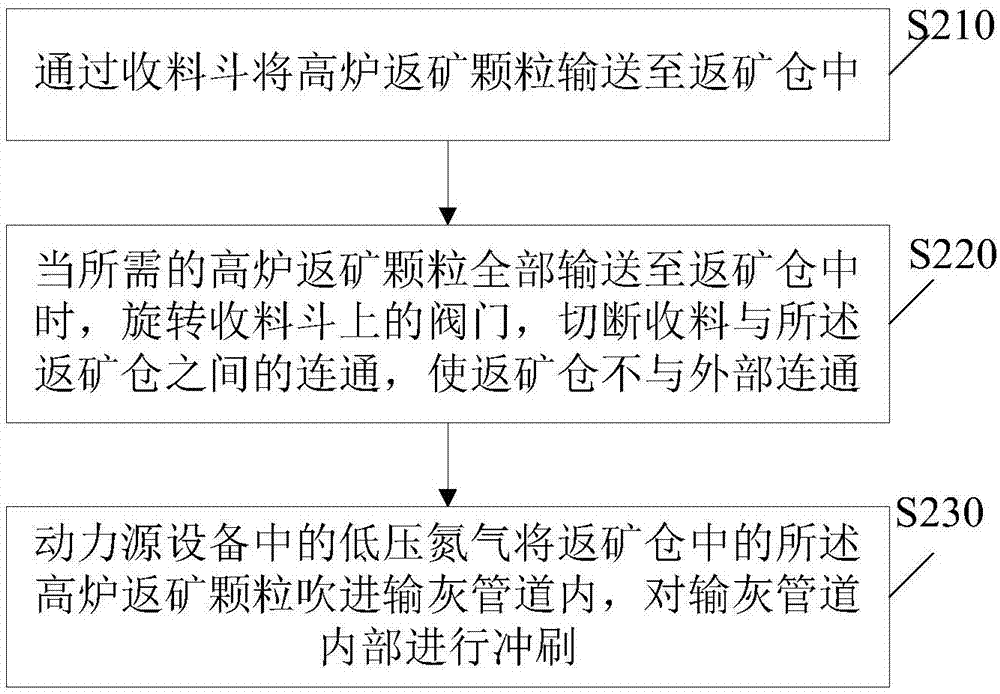

[0029] In order to illustrate the blast furnace cloth bag pneumatic ash conveyin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com