Heat-storage heating equipment for heating by using gas

A gas heating and heat storage technology, which is applied to lighting and heating equipment, central heating, and can solve problems such as environmental hazards of coal heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the content, features, and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

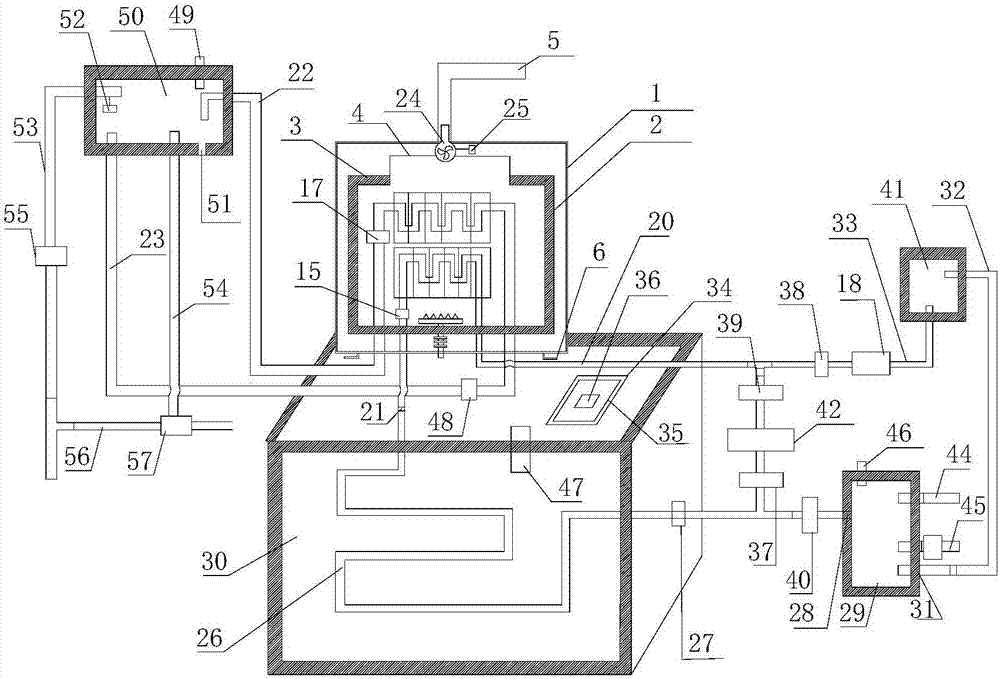

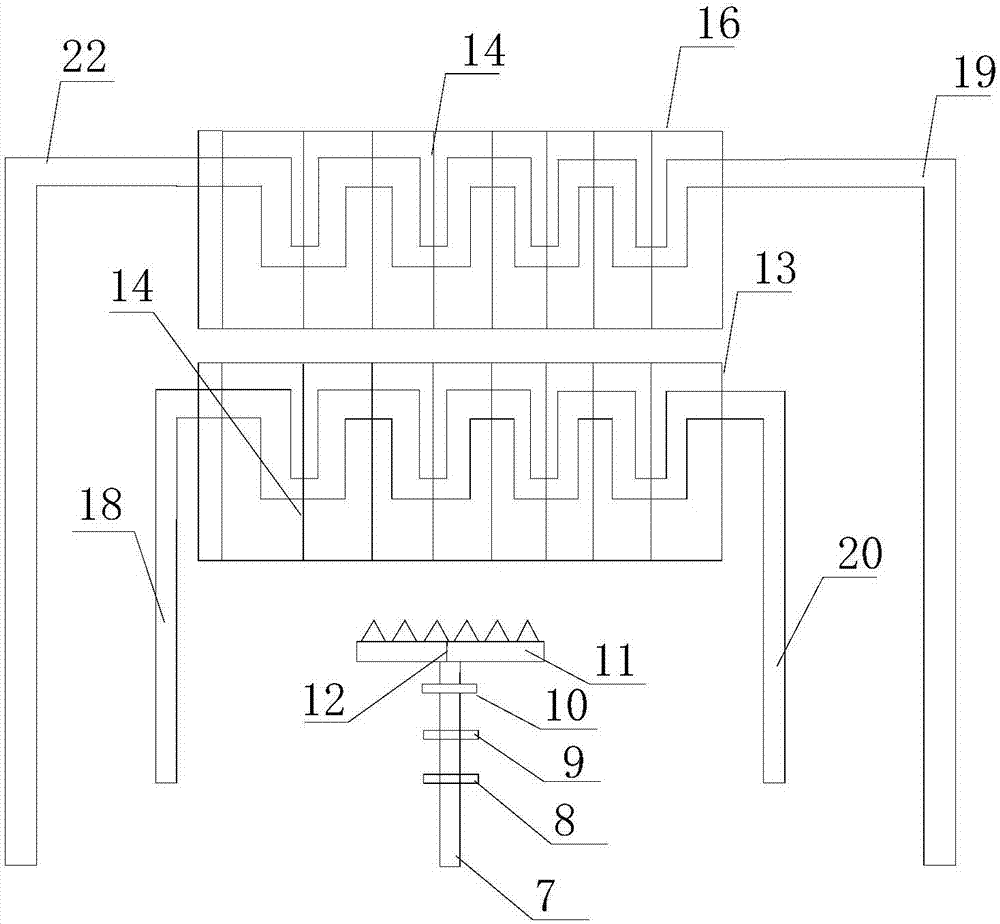

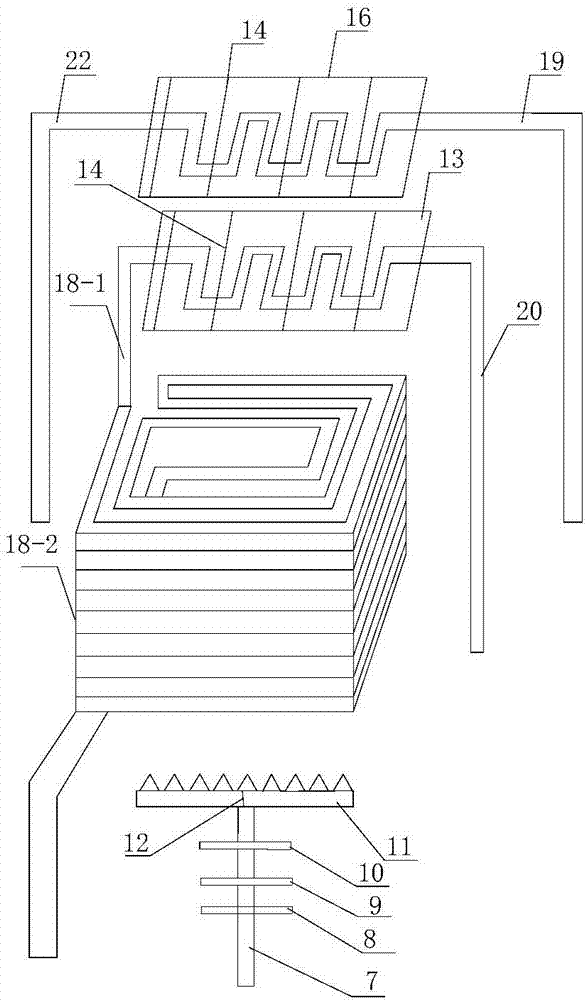

[0040] See Figure 1 to Figure 6 , A gas-fired heat storage heating equipment, including:

[0041] A phase change material heat storage tank 30 containing a phase change material inside. The phase change material heat storage tank 30 is provided with a heat transfer oil tube 26; the top of the phase change material heat storage tank 30 is provided with a feeding port 34. A feeding opening cover 35 is installed at the position of the feeding opening 34, and a feeding box exhaust hole 36 is opened on the feeding opening cover 35;

[0042] A heating box, which is provided with a water heater 16, an oil heater 13, and a gas heating device;

[0043] Water storage tank 50, oil storage tank 41 and heating and heat exchange tank 29; among them:

[0044] The water heater 16 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com