Motor punching sheet of heating compressor of heat pump, motor, and compressor

A technology for motor punching and compressor, applied in the field of compressors, can solve the problems of long running time of outlet water temperature, motor overheating and burning loss, etc., and achieve the effect of ensuring long-term normal operation, avoiding magnetic density saturation, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

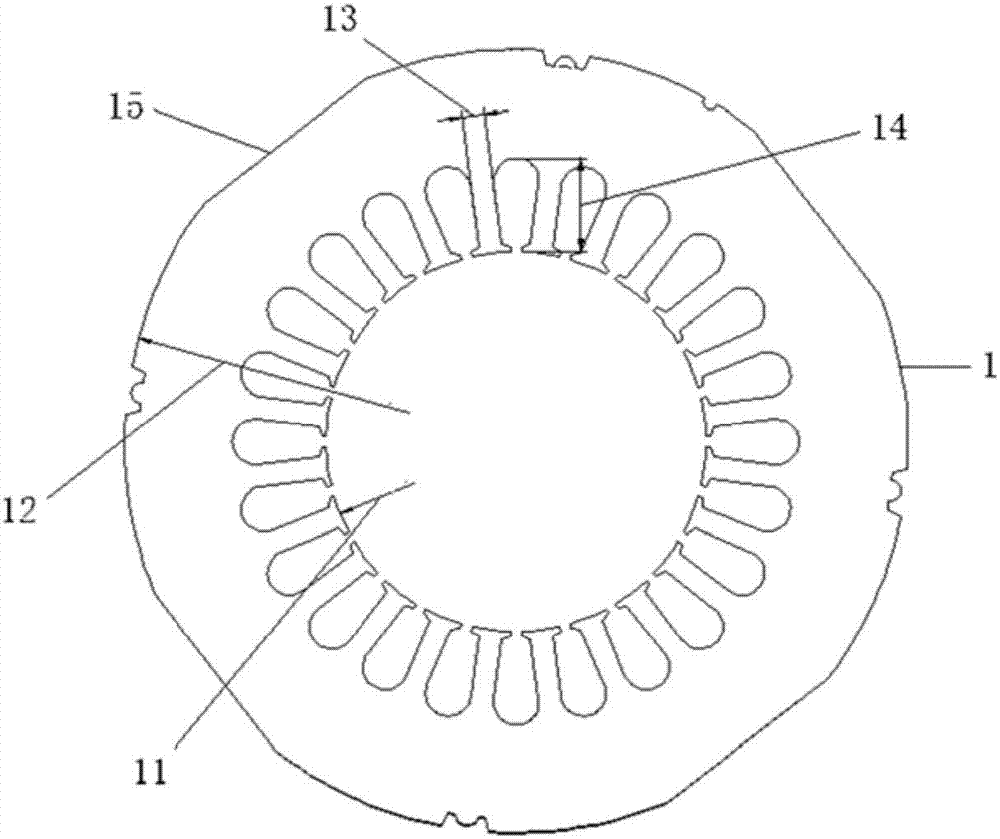

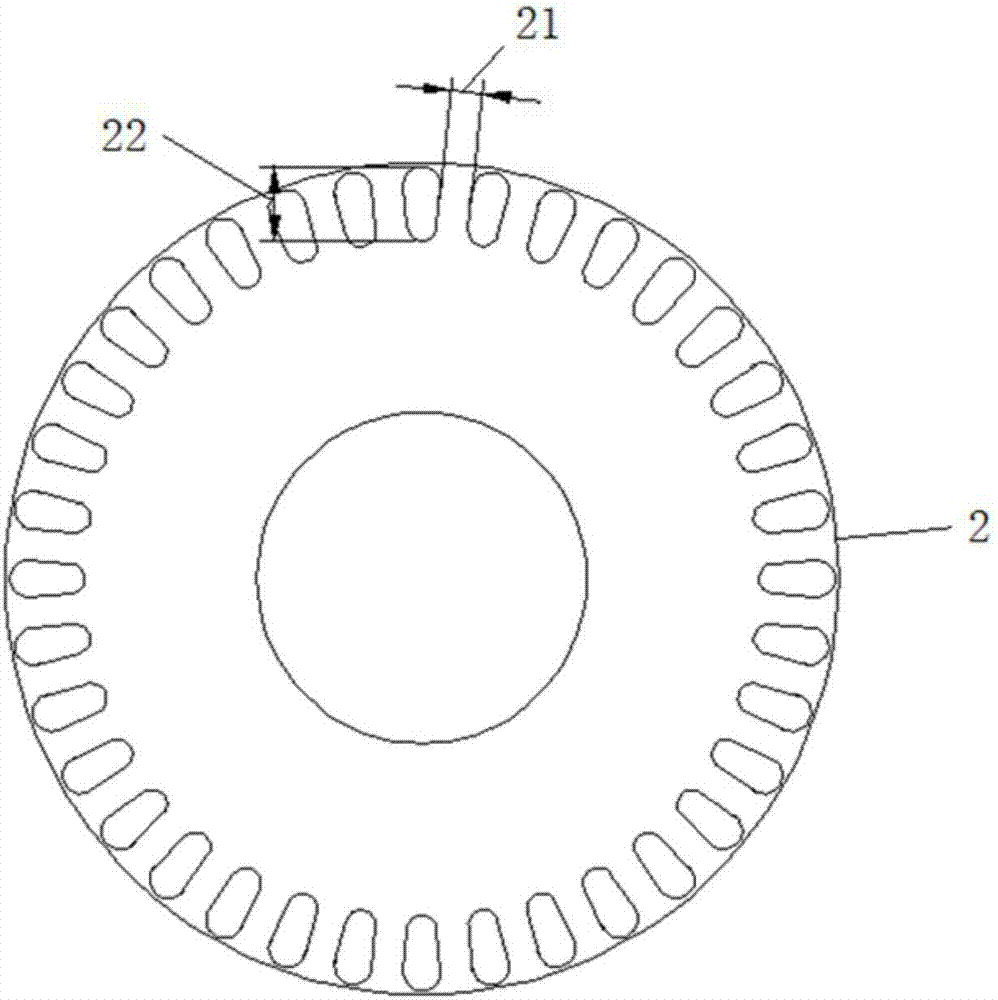

[0031] This embodiment provides a heat pump heating compressor. In the motor stamping plate used by the motor of the compressor, four trimming edges are arranged on the stator stamping plate, and the four trimming edges are symmetrically located on the outside of the stator stamping plate. On the arc, and the size and shape of the four cutting edges are all the same, so that the four cutting edges are symmetrically distributed at 90 degrees.

[0032] The distance between two parallel trimmings is 156 mm, and the outer diameter of the stator is 163 mm, that is, the ratio of the distance between the two symmetrical trimmings to the outer diameter of the stator punch is 0.96;

[0033] The number of slots for the stator punch is 36, the number of slots for the rotor punch is 24, and the number of slots for the stator punch is 12 more than the number of slots for the rotor punch;

[0034] The inner diameter of the stator is 80mm, that is, the optimal value of the ratio of the inner...

Embodiment 2

[0039] This embodiment provides a heat pump heating compressor. In the motor stamping plate used by the motor of the compressor, four trimming edges are arranged on the stator stamping plate, and the four trimming edges are symmetrically located on the outside of the stator stamping plate. On the arc, and the size and shape of the four cutting edges are all the same, so that the four cutting edges are symmetrically distributed at 90 degrees.

[0040] The distance between two parallel trimmings is 161 mm, and the outer diameter of the stator is 177 mm, that is, the ratio of the distance between the two symmetrical trimmings to the outer diameter of the stator punch is 0.91;

[0041] The number of slots for the stator punch is 36, the number of slots for the rotor punch is 24, and the number of slots for the stator punch is 12 more than the number of slots for the rotor punch;

[0042] The inner diameter of the stator is 80mm, that is, the ratio of the inner diameter to the oute...

Embodiment 3

[0046] This embodiment provides a heat pump heating compressor. In the motor stamping plate used by the motor of the compressor, four trimming edges are arranged on the stator stamping plate, and the four trimming edges are symmetrically located on the outside of the stator stamping plate. On the arc, and the size and shape of the four cutting edges are all the same, so that the four cutting edges are symmetrically distributed at 90 degrees.

[0047] The distance between two parallel trimmings is 143.5 mm, and the outer diameter of the stator is 145 mm, that is, the ratio of the distance between the two symmetrical trimmings to the outer diameter of the stator punch is 0.99;

[0048] The number of slots for the stator punch is 36, the number of slots for the rotor punch is 24, and the number of slots for the stator punch is 12 more than the number of slots for the rotor punch;

[0049] The inner diameter of the stator is 80mm, that is, the ratio of the inner diameter to the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com