Abrasive block adapting device and tread cleaner

A switching device, a technology for cleaning the tread, which is applied in the direction of vehicle cleaning, transportation and packaging, vehicle maintenance, etc., and can solve the problem that the installation to the tread cleaner cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

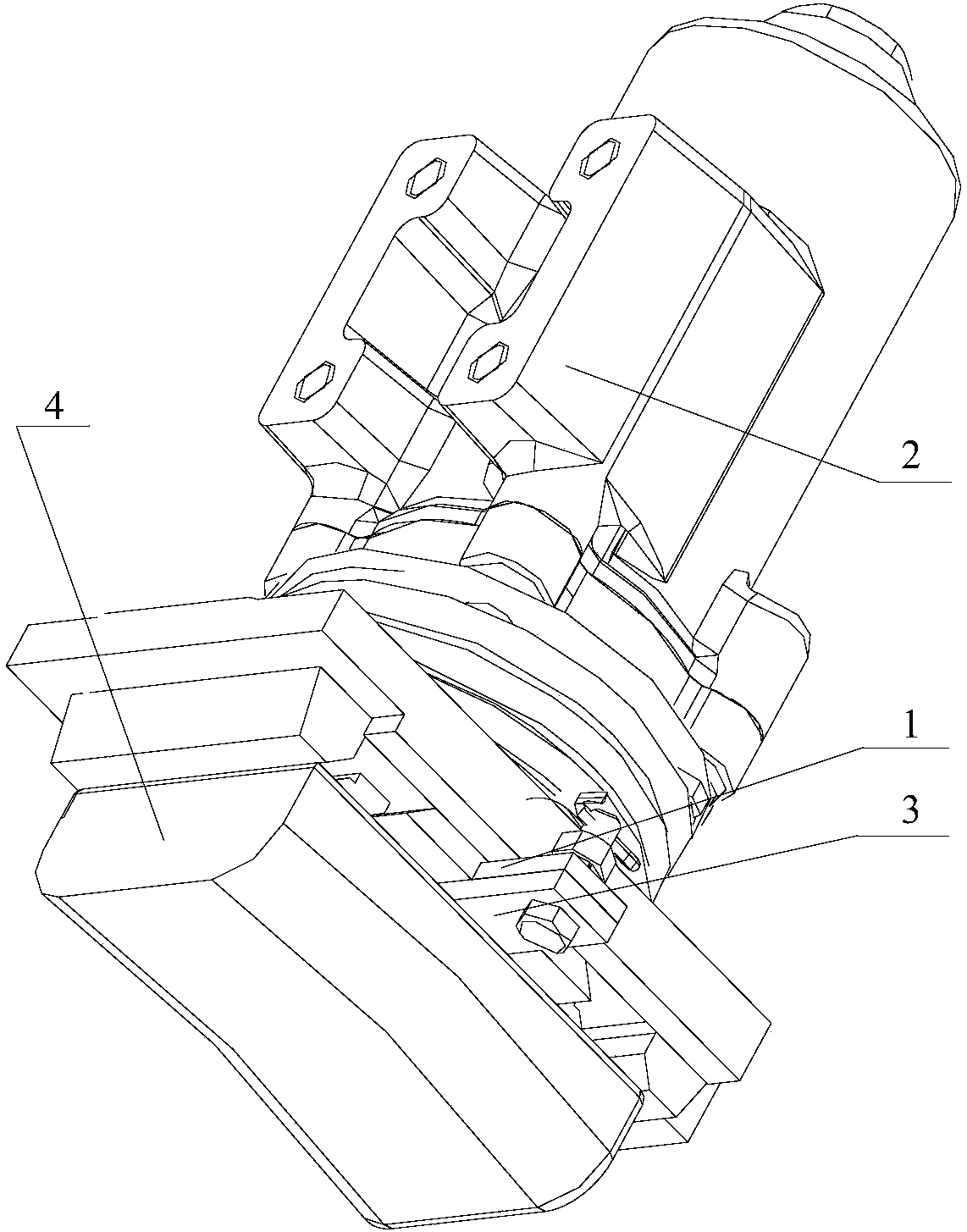

[0039] Such as Figure 1-6 As shown, the present invention discloses a grinder adapter device, which can realize the installation of the special-shaped grinder 4 on the tread cleaner 2 of the V-groove.

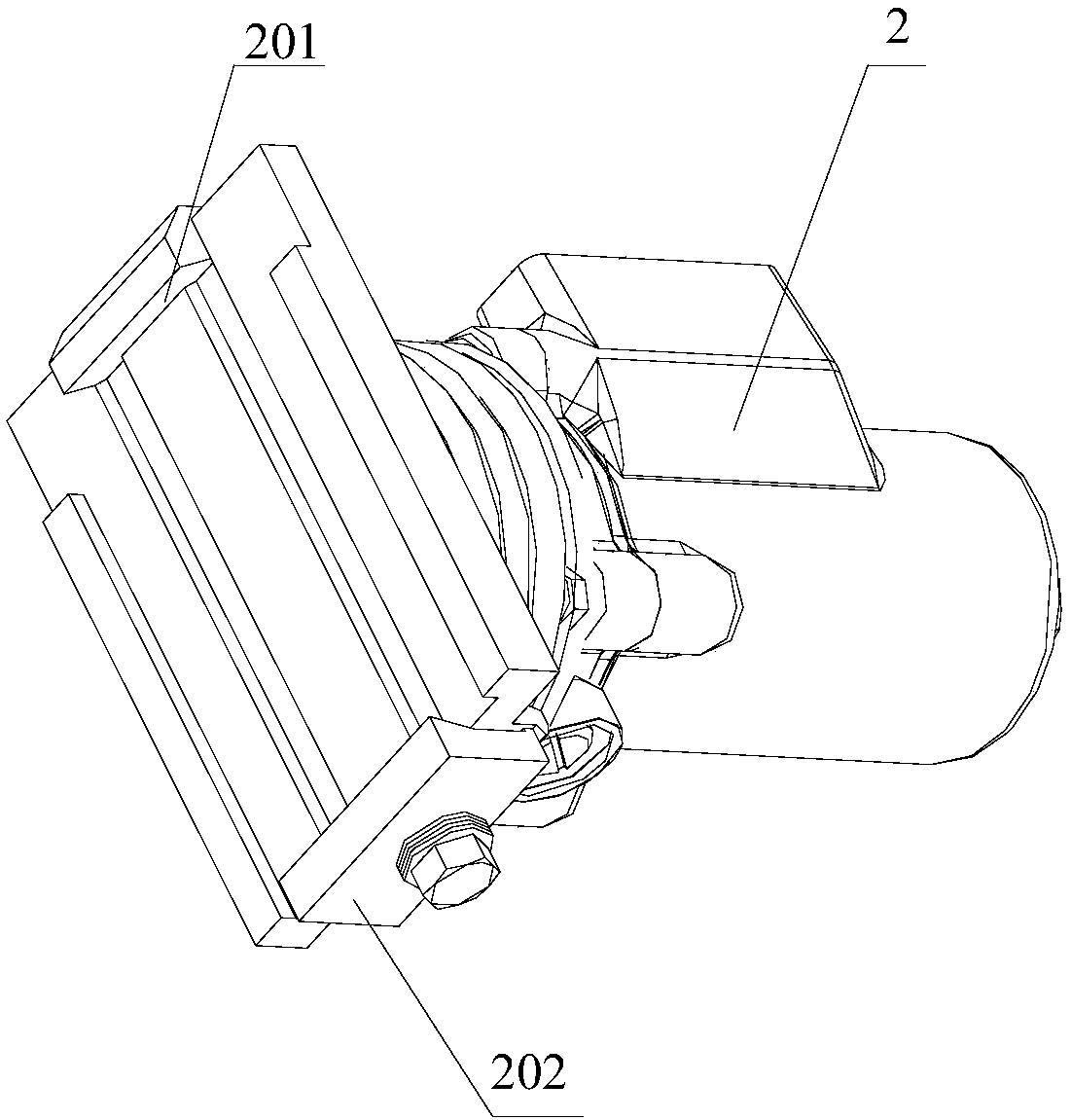

[0040] The grinder adapter includes a cover plate 1 and a base plate 3 . Wherein, the two sides of cover plate 1 are provided with V-shaped slide rail 101, and V-shaped slide rail 101 can be installed in the V-shaped groove 201 on tread sweeper 2, and can fix cover plate by pressing plate 202 on tread sweeper 2 1. One side of the tread cleaner 2 is provided with a V-shaped groove 201 , and the other side is used for installing the fixed cover 1 , and the fixed cover 1 is fixedly connected by the fixing bolt 6 .

[0041] The base plate 3 is detachably connected to the cover plate 1 , specifically by bolts 6 or buckles. The special-shaped grinder 4 to be connected is provided with a mounting plate 401, and when the base plate 3 and the cover plate 1 are connected together, a s...

Embodiment 2

[0044] In the second embodiment provided by the present invention, the structure of the grinder adapter device in this embodiment is similar to that of the first embodiment, and the similarities will not be repeated, only the differences will be introduced. place.

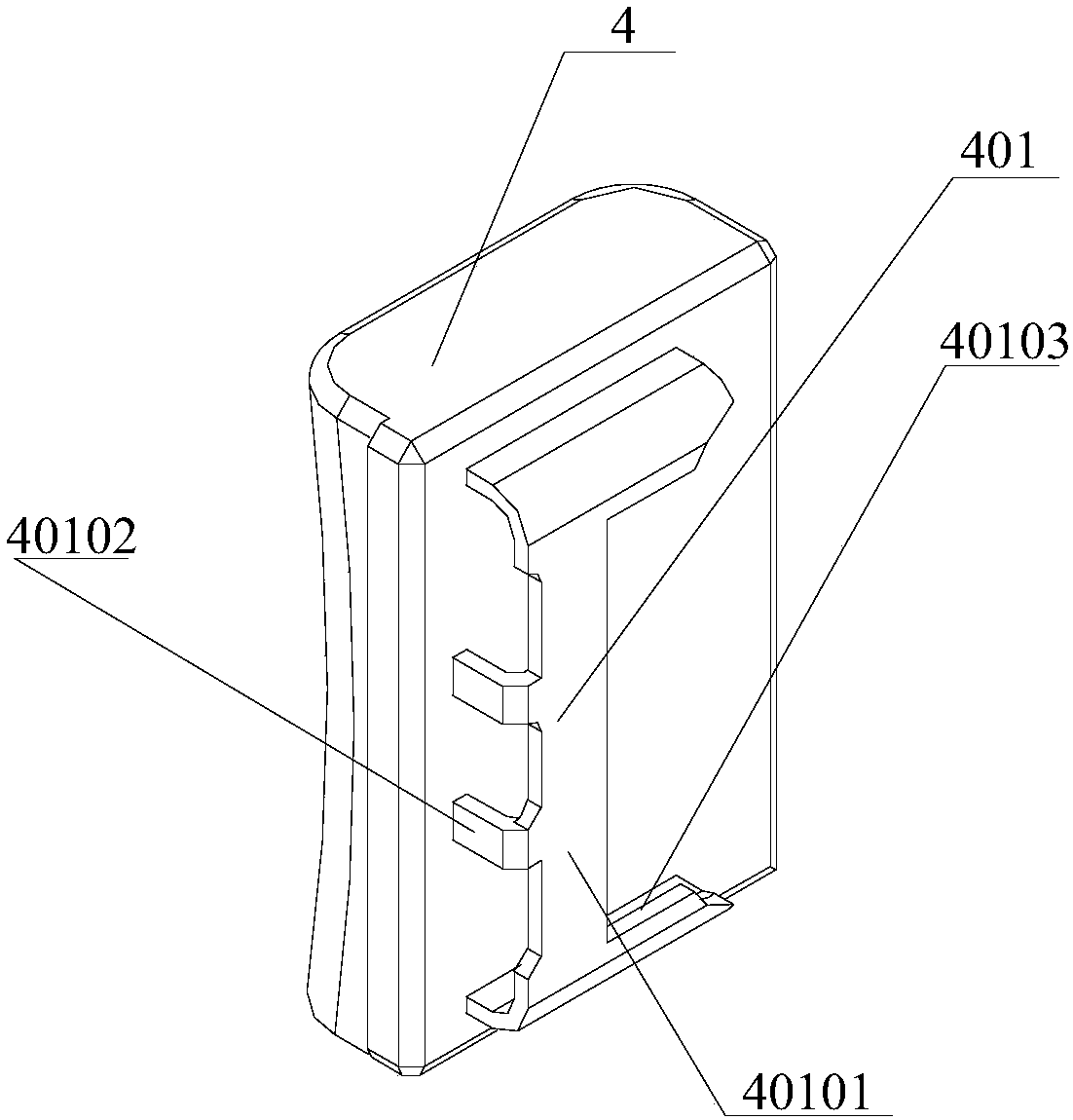

[0045] In this embodiment, it is specifically disclosed that the mounting plate 401 includes a mounting plate main body 40101 and a limiting plate 40102 . Wherein, the mounting plate main body 40101 is installed on the special-shaped grinder 4, the limiting plate 40102 is arranged on the outlet end of the mounting plate main body 40101, and the top of the substrate 3 can abut against one end of the limiting plate 40102, and the other end of the limiting plate 40102 One end can abut against the limit block 102 on the cover plate 1 .

[0046] Further, the present invention discloses that the installation board 401 further includes first guide rails 40103, the first guide rails 40103 are arranged on both sides of the...

Embodiment 3

[0055] In this embodiment, a tread cleaner is specifically disclosed, including the grinding wheel adapter device in any one of the above embodiments.

[0056] Since the tread cleaner disclosed in the present invention includes the grinder adapter device in any one of the above embodiments, the beneficial effects of the grinder adapter device are included in the tread cleaner disclosed in the present invention.

[0057] In the present invention, "first", "second", etc. are for distinction in description, and have no other special meanings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com