A device for automatically picking up discs in stacks and placing multiple discs individually

An optical disc, automatic technology, applied in transportation and packaging, packaging, chucks, etc., can solve problems such as low production efficiency, increased cost, and unrealistic

Active Publication Date: 2019-10-01

BEIJING ZHONGKE KAIDI SOFTWARE CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The actual production process of optical discs is often mass production. During the production process, a stack of optical discs is often produced at the end of the production line at the same time, but the mass-produced optical discs need to be packaged in single or multiple sheets at the end of the packaging line. This process includes the production of optical discs in the production room. From manual movement to the packaging end, the packaging end classifies according to different discs, single or multiple packaging, that is, the four processes of picking, transporting, sorting, and packaging. Among them, the two links of transport and sorting greatly increase the production cost. How to optimize Woolen cloth?

Single-sheet transportation is unrealistic, so the cost of the enterprise is too high, and the production efficiency is too low. The existing production is mostly manual batch transportation. The disadvantage is that a classification process needs to be added after transportation. What about production efficiency? This requires a solution to the problem of picking up discs in stacks at the end of the production line and moving them to the end of the packaging line to place single or multiple sheets. After the discs are produced, the traditional disc manufacturers usually pack the discs manually before packaging. Moving from the end of the production line to the end of the packaging line increases the workload of the laborers in the production process and increases the cost. In addition, due to the particularity of the disc and the limitations of labor in the actual production process, the movement of the disc before manual packaging In the process of placement and placement, on the one hand, the staff may print fingerprints on the CD in repeated labor, on the other hand, the efficiency of the labor will decrease with the extension of the working time and the labor cost will become higher and higher.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

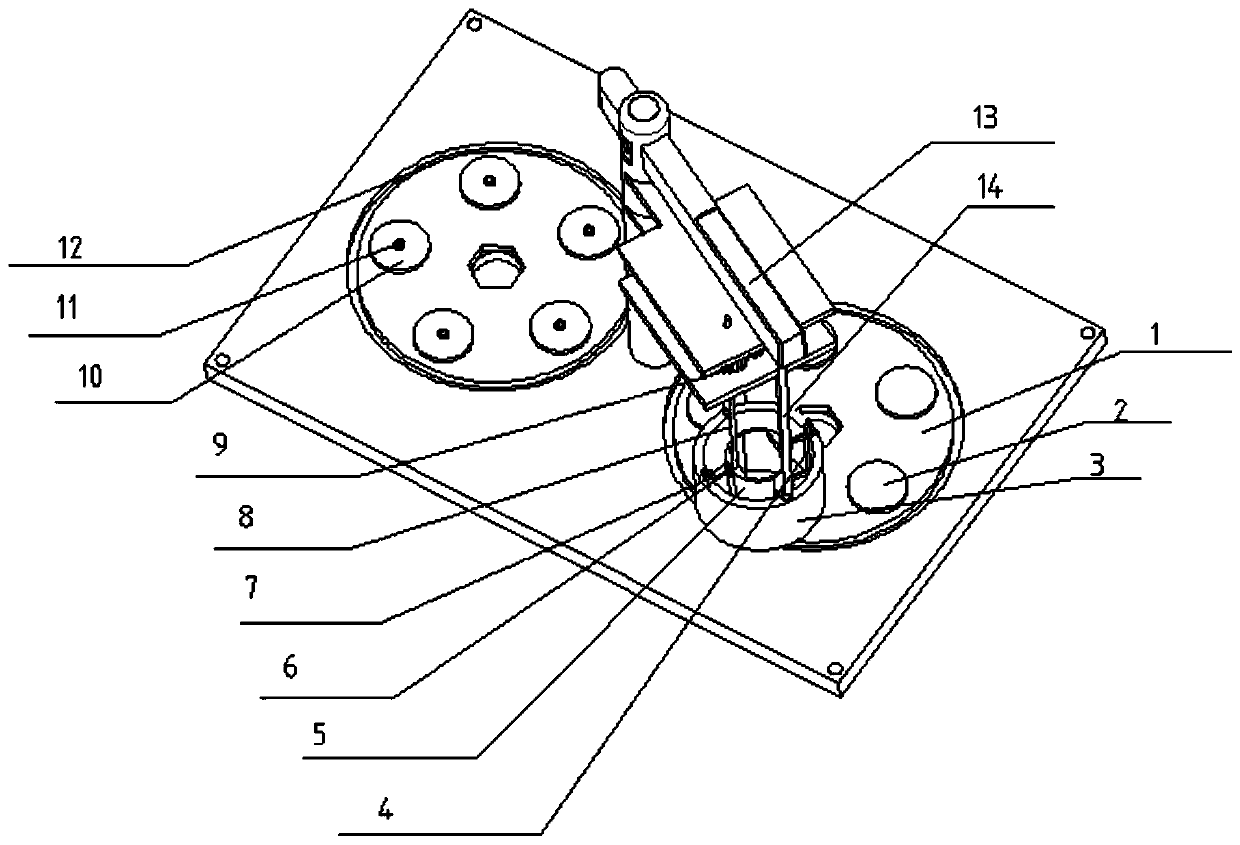

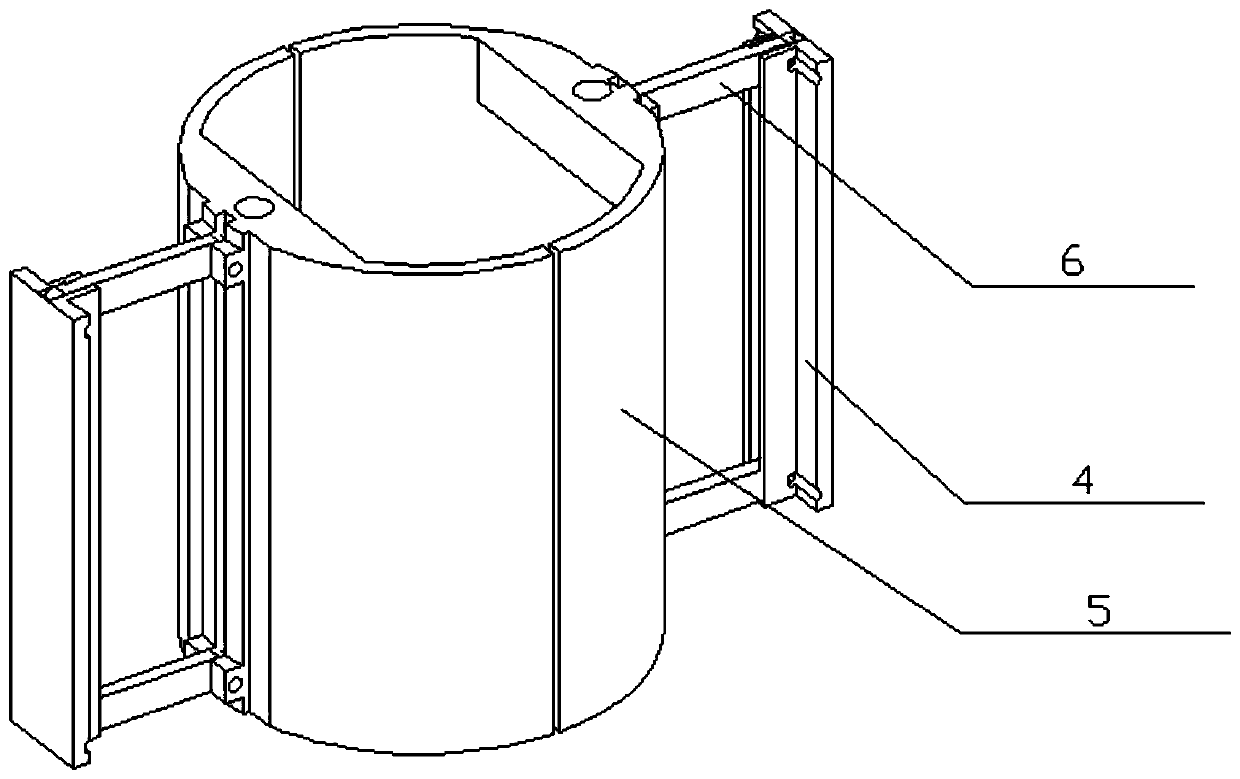

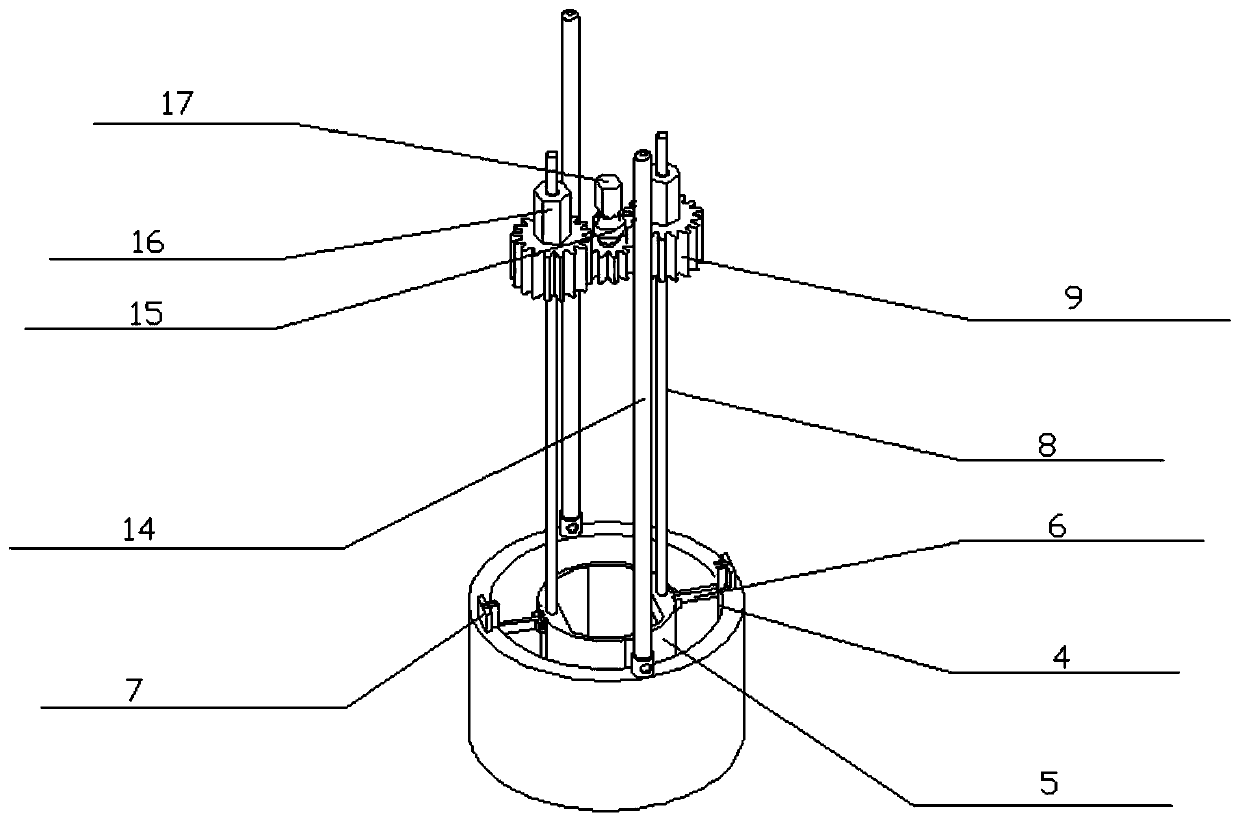

The invention belongs to optical disk producing equipment, and provides a device for automatically picking piles of optical disks and placing one or more optical disks. The device is composed of a rotary picking disc, a central shaft and a rotary placing disc. The rotary picking disc and the rotary placing disc are mounted on the two sides of the central shaft correspondingly. The rotary picking disc is composed of optical disk placing seats. The central shaft is composed of a picking hand, a picking hand shell, a picking moving rod, a picking pressing rod, a pressure reducing slide rod, a locking slide block, a pressurizing screw rod, a pressurizing nut, a transmission gear and a motor. The rotary placing disc is composed of a placing seat and a separating buckle. When optical disks are produced in batches at a production line end, the optical disks can be directly placed on the optical disk placing seats of the rotary picking disc, and then the device can be used for automatically picking the optical disks, moving and placing the optical disks one by one; and the optical disks can be directly packaged after being picked and then automatically placed one by one or in piles, the classification procedure is omitted, the whole picking, moving and placing process is automatically completed, production efficiency can be greatly improved, and the workload is reduced.

Description

technical field The present invention relates to a kind of equipment that can be used in mass production of optical discs to automatically pick up and move discs in stacks and place discs individually. The device for placing single or multiple sheets behind the packaging line belongs to the optical disc production equipment category. Background technique The actual production process of optical discs is often mass production. During the production process, a stack of optical discs is often produced at the end of the production line at the same time, but the mass-produced optical discs need to be packaged in single or multiple sheets at the end of the packaging line. This process includes the production of optical discs in the production room. From manual movement to the packaging end, the packaging end classifies according to different discs, single or multiple packaging, that is, the four processes of picking, transporting, sorting, and packaging. Among them, the two links ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65G47/90B65G47/88B25J15/00B65B35/36

Inventor 包莉丽

Owner BEIJING ZHONGKE KAIDI SOFTWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com