Curling preventive structure for folded edges of hems

A frontier and hem technology, applied in the field of sewing machines, can solve problems such as increased production costs, high difficulty, and low work efficiency, and achieve the effects of improving work efficiency, wide application, and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

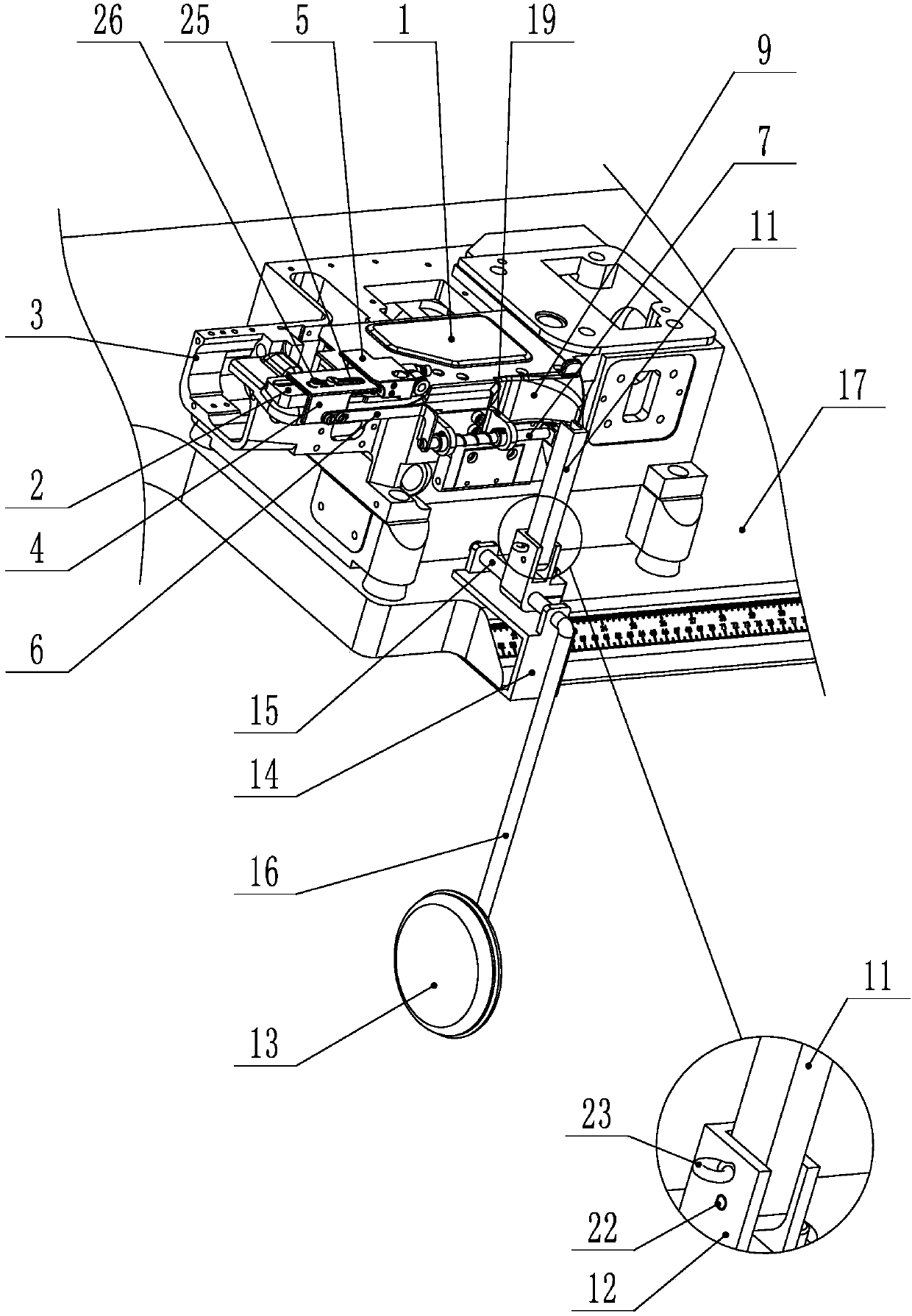

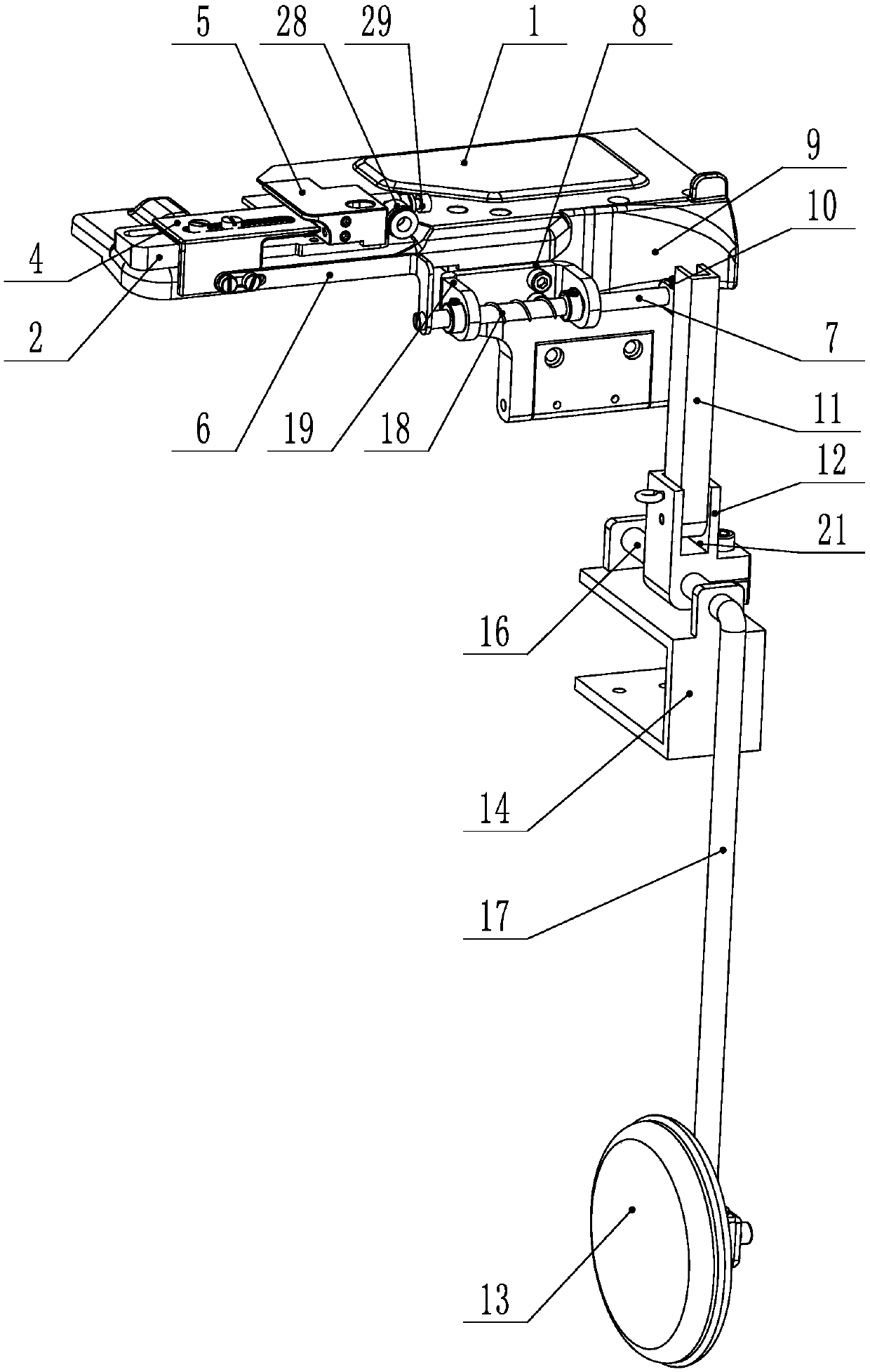

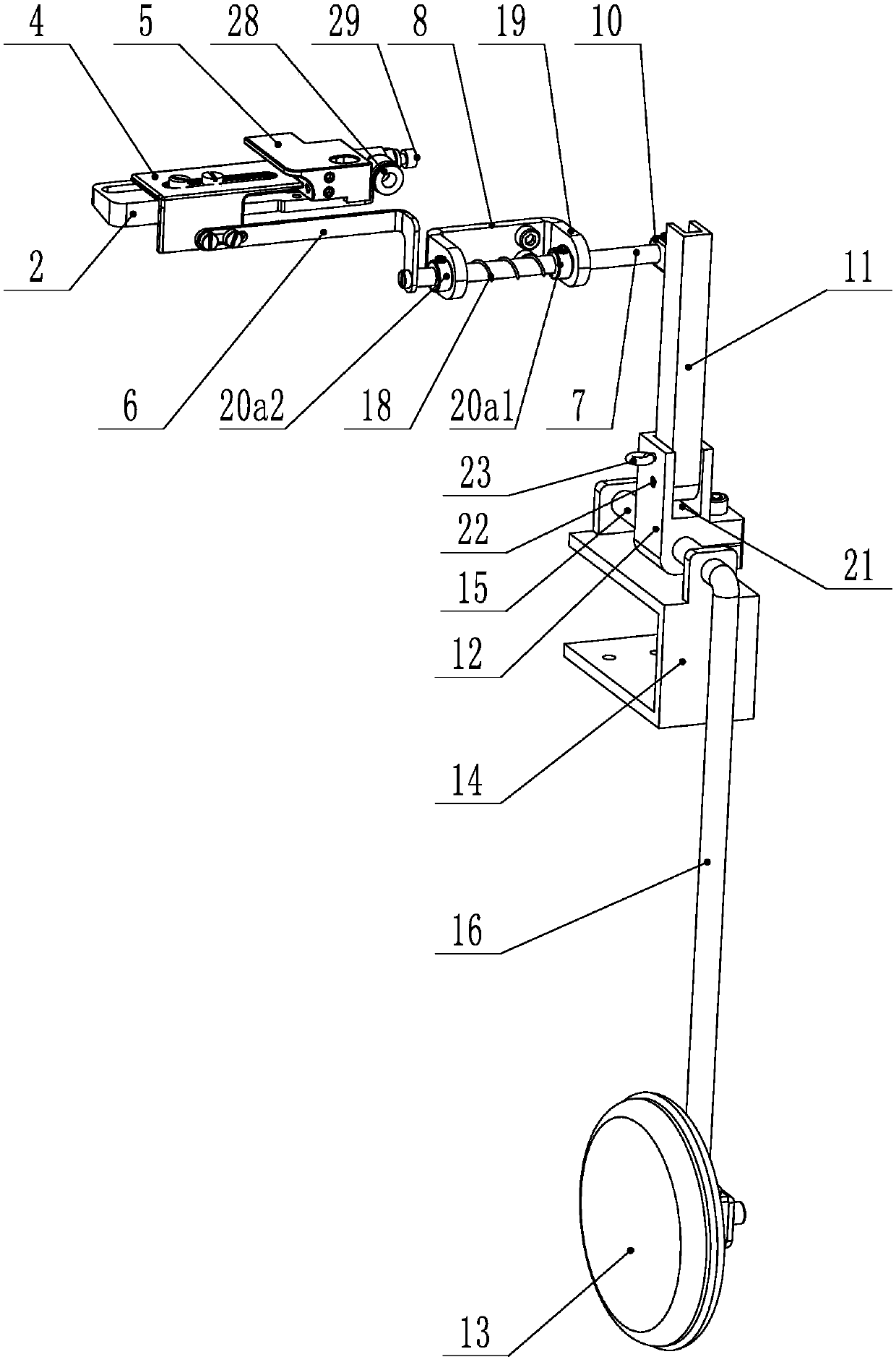

[0028] The present invention will be further described below with specific examples, see figure 1 -9:

[0029] A hem folding anti-rolling structure includes a push plate seat 2 arranged on a flat surface of a sewing table 1, and the sewing table 1 is installed on a machine shell 3. A push plate 4 is provided on the push plate base 2, and the right end of the push plate 4 is suspended on the push plate base 2. The upper plane of the push plate seat 2 is a stepped surface, and the plane at the right end is lower than the plane at the left end. A gap is formed between the right end of the push plate 4 and the right end of the push plate seat 2, that is, it is suspended to facilitate folding. A stopper 5 is provided on the right side of the push plate 4, and a blowing channel for blowing flat cloth is provided on the stopper 5. The blowing channel is connected with the gas source through the gas valve.

[0030] In order to conveniently adjust the left and right positions of the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com