Stepped displacement fracturing pump casting method based on combined type perforation

A combined type, fracturing pump technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of fracture complexity and extension distance, reduce recovery rate, etc., and achieve long-term diversion The effect is stable, the effect of increasing the size and increasing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

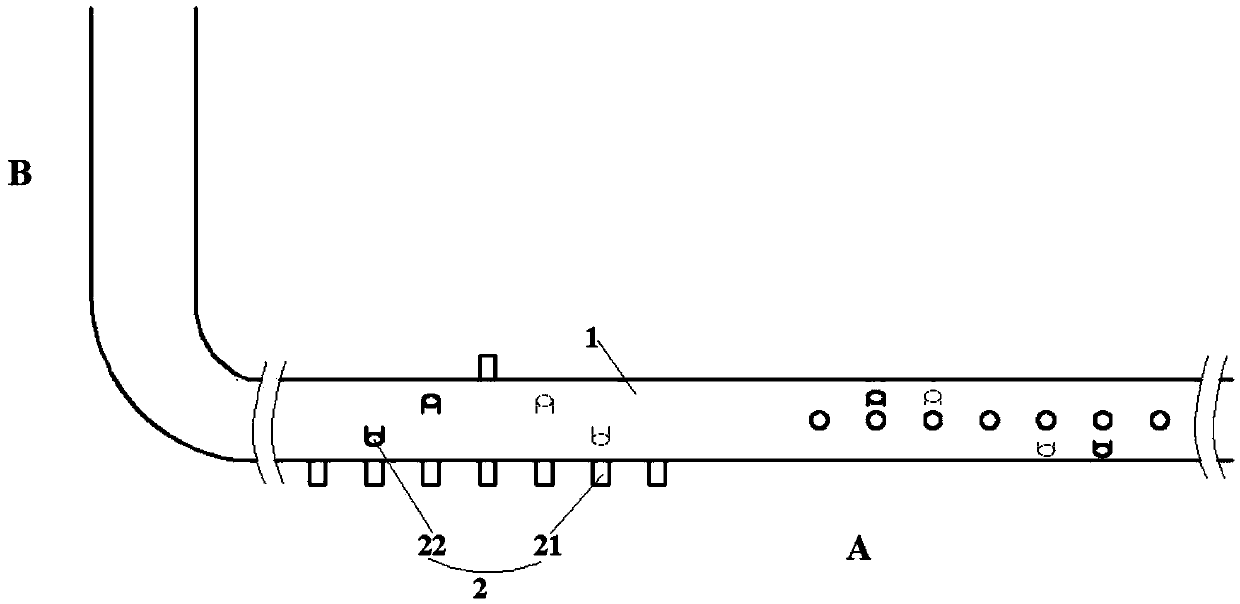

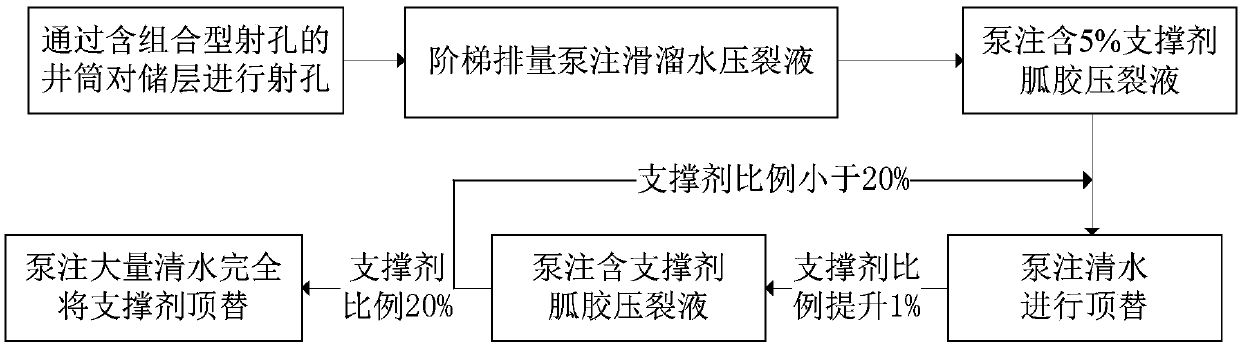

[0041] Taking a shale gas fracturing well in the Sichuan Basin as an example, the embodiment of the present invention provides a method for performing stepped displacement fracturing pumping on reservoirs based on combined perforation. The method should at least include: The perforated wellbore is used to perforate the reservoir, the perforation method and parameters are optimized; steps such as step displacement fracturing and pumping are carried out to the perforated reservoir.

[0042] The basic parameters of the reservoir are: reservoir thickness 38m, temperature 95°C, porosity 4.28%, formation pressure 38.94MPa, formation pressure coefficient 1.55, closure pressure 54.8MPa, average Poisson's ratio of reservoir shale 0.17, average Young's modulus The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com