Quartz plate flame polishing device

A flame polishing and quartz plate technology, which is applied in the field of quartz products, can solve problems such as instability and uneven brightness on the surface of the quartz plate, and achieve the effect of uniform brightness and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

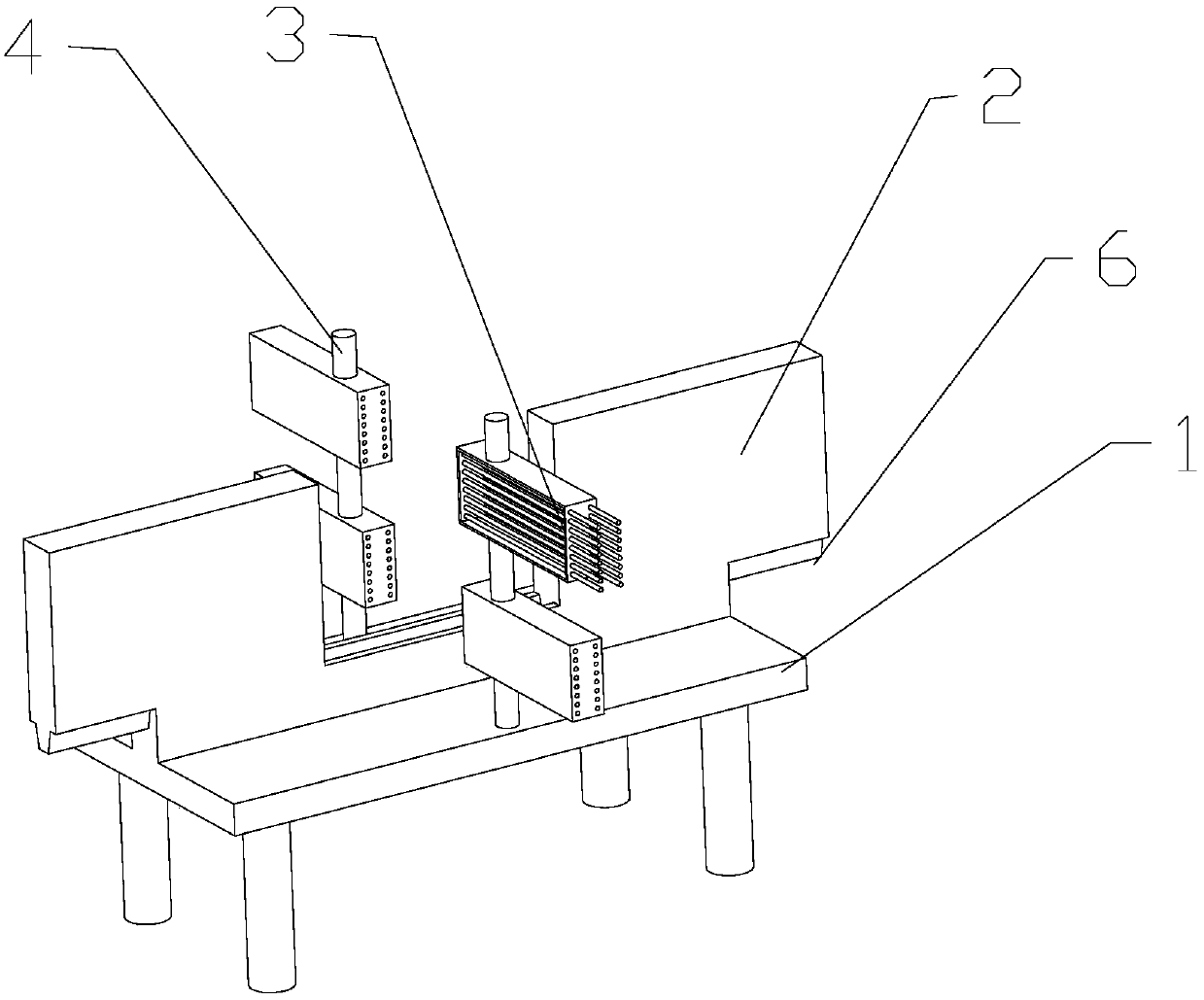

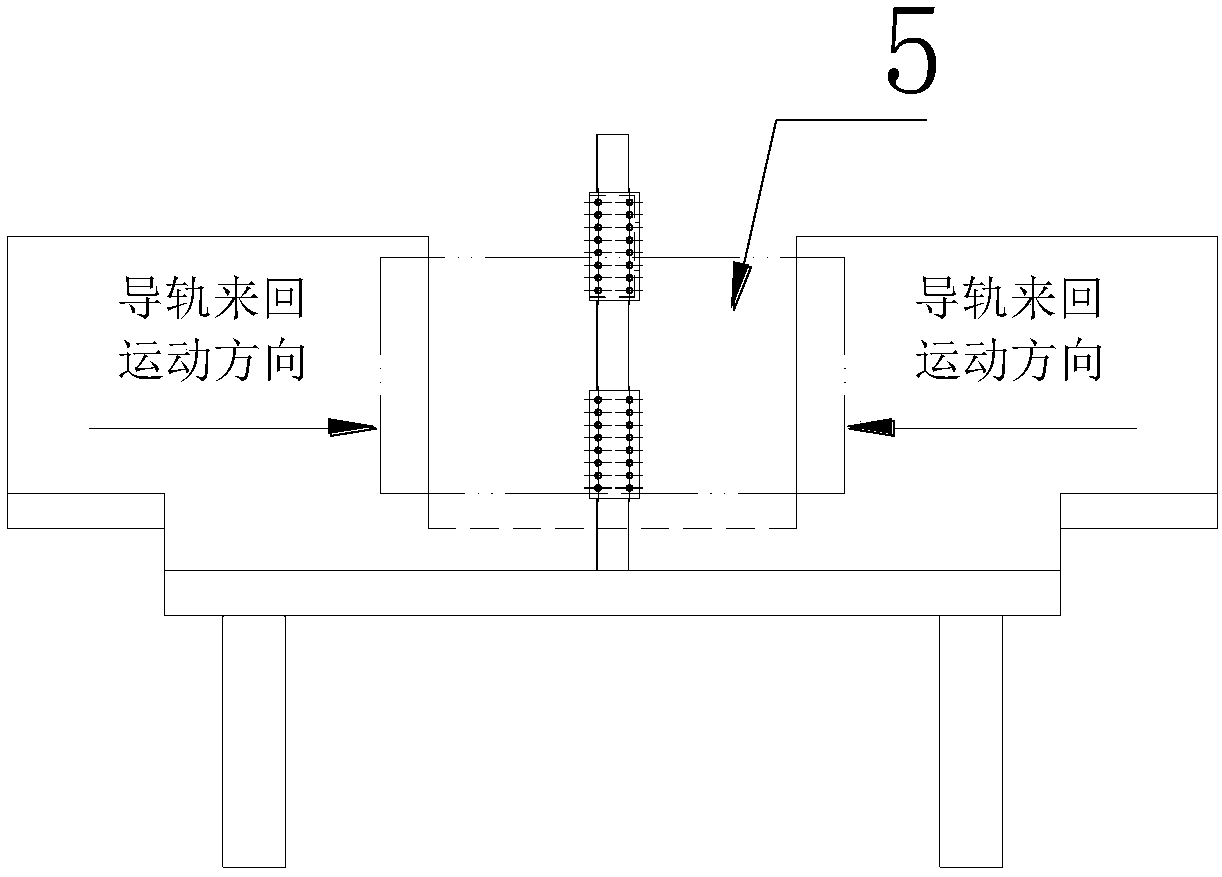

[0016] like figure 1 and 2 As shown, the quartz plate flame polishing device of the present invention has a base, and a guide rail is provided on the surface of the base, and the clamping carrier on the guide rail can move left and right along the guide rail. The clamping carrier is in a concave shape for clamping the quartz plate, and the quartz plate is just located in the notch of the concave shape after being clamped by the clamping carrier.

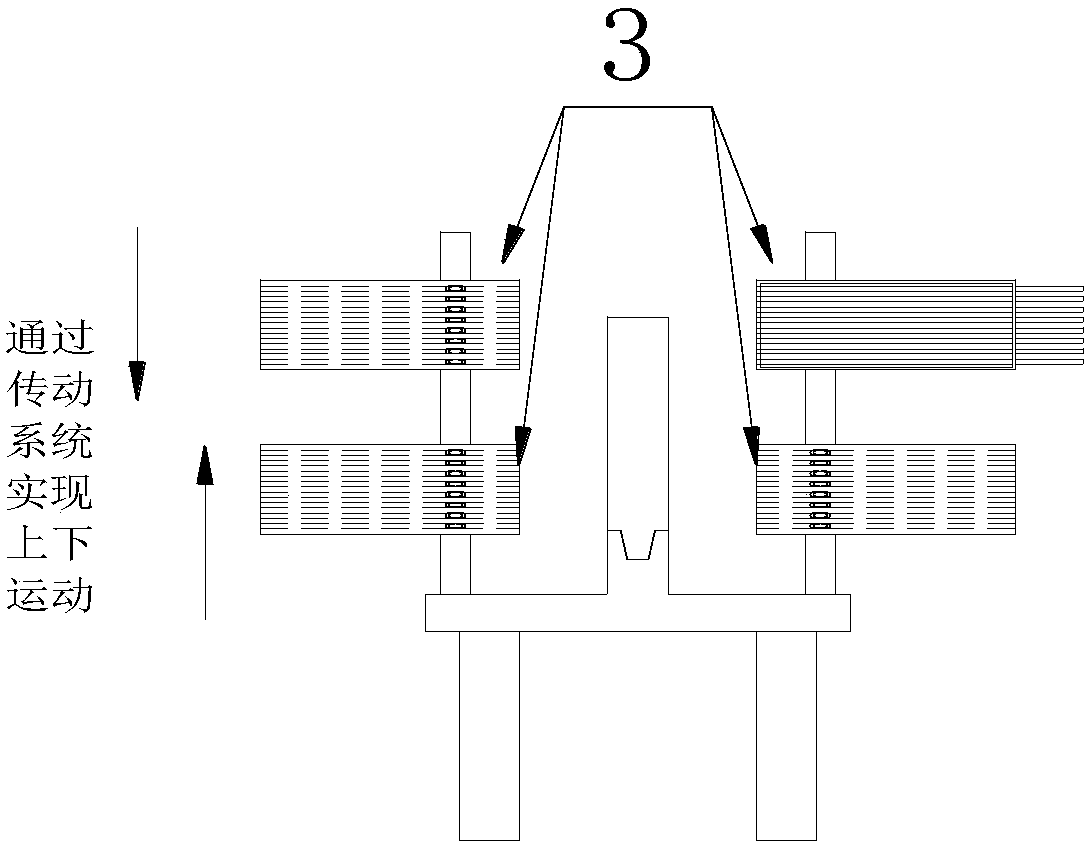

[0017] Along the surface of the base and perpendicular to the guide rail, two pairs of opposite flame polishing guns are provided, facing the notch of the holding carrier, for flame polishing the quartz plate from both sides. The flame polishing gun is fixed on the adjustment rod, and the adjustment rod is perpendicular to the surface of the base. The adjustment rod can move up and down to realize the up and down movement of the flame polishing gun.

[0018] By adjusting the flame size of the flame polishing gun, the speed control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com