Spraying structure for oil well mining and construction

A technology of oil wells and spray holes, which is applied in the field of spray structure for oil well mining construction, can solve the problems of easy safety accidents and low safety and reliability, and achieve the effects of convenient and continuous rising, improving atomization effect and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

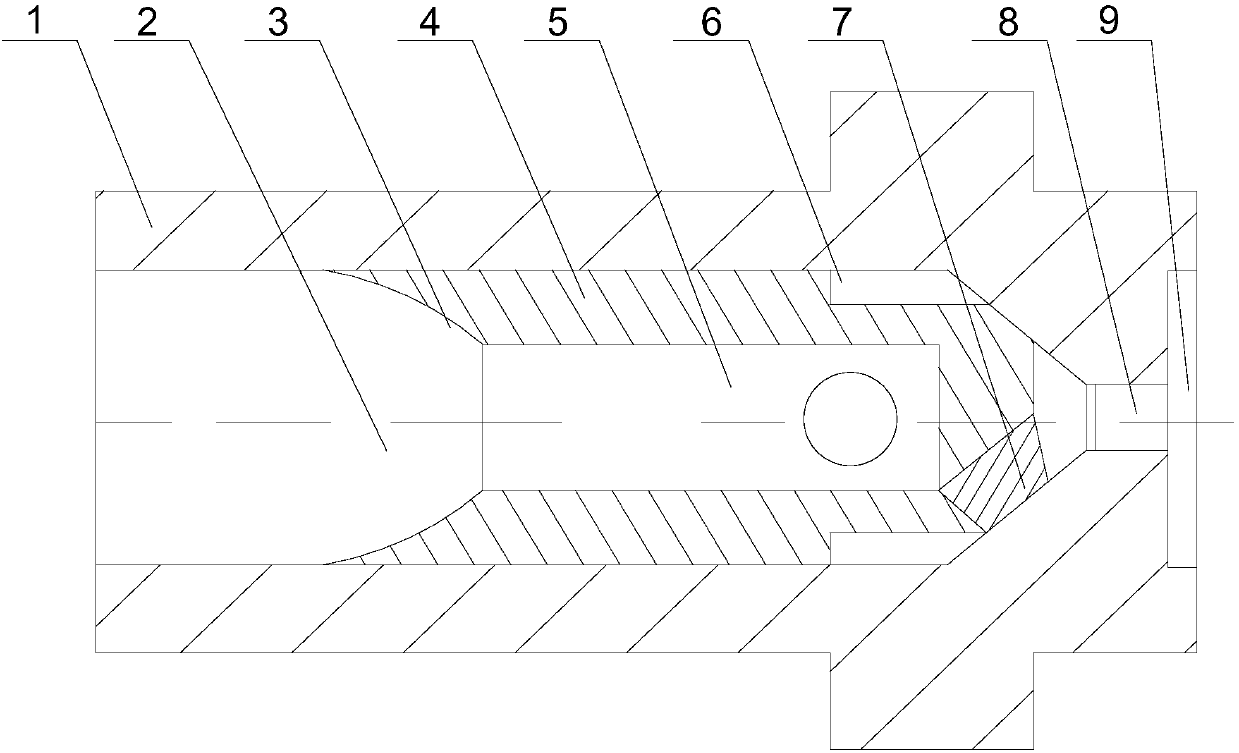

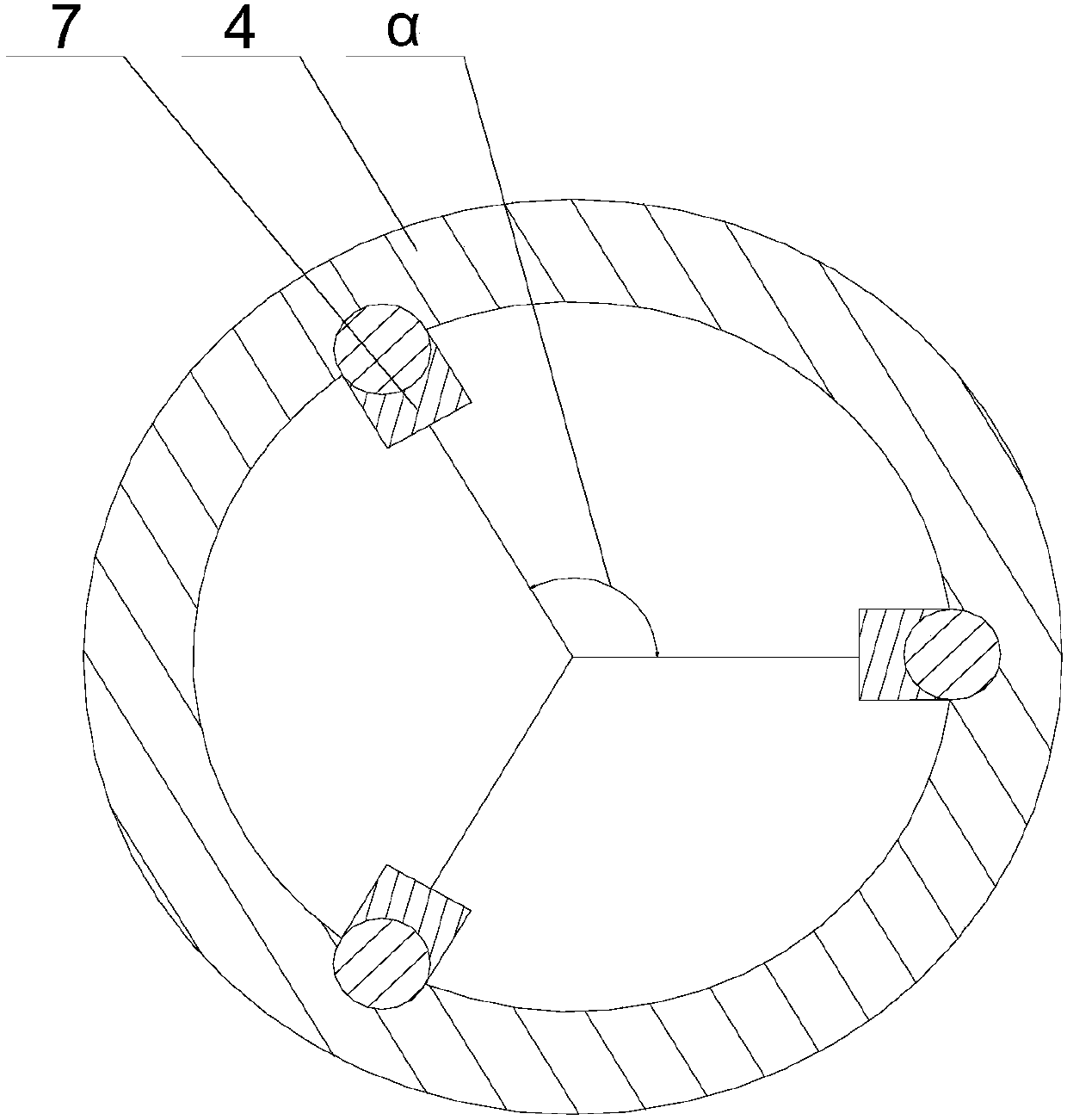

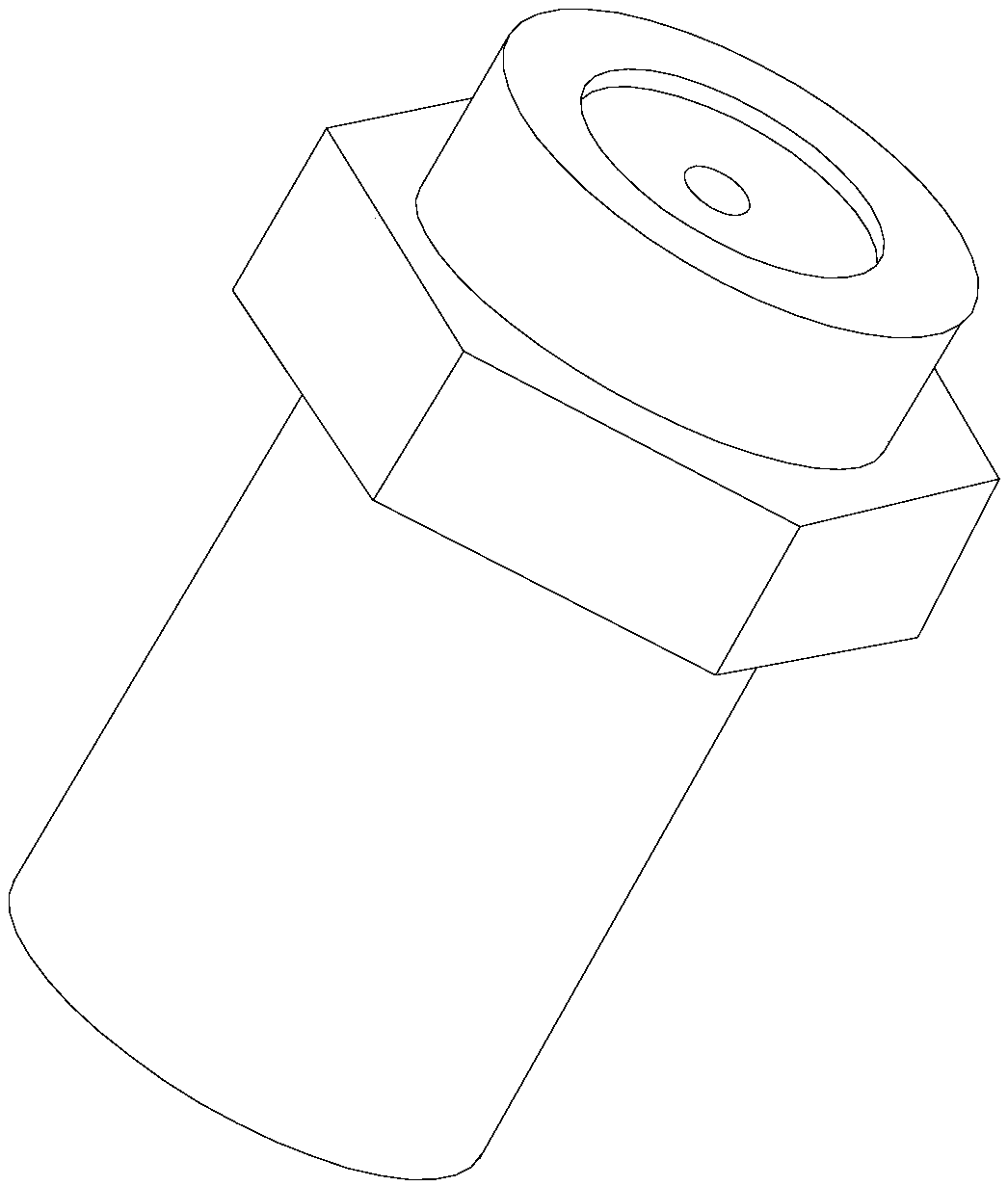

[0023] Such as Figure 1~4 As shown, this embodiment includes a core body 4 and a housing 1 sleeved outside the core body 4, the end of the housing body 1 is provided with a spray hole 8, and an inner conical surface 3 is provided at one end of the core body 4, and The inner conical surface 3 and the inner wall of the housing 1 form an air intake cavity 2, the other end of the core body 4 has a through hole facing the jet flow hole 8, and a plurality of swirl blades 7 are installed on the inner wall of the through hole, and The through hole and the inner wall of the core 4 form a swirl cavity 5 .

[0024] Fix the nozzle at the gas outlet end of the gas well. When the gas-liquid two-phase mixture in the gas well starts to rise under the pressure in the well, the gas-liquid mixture enters the intake cavity 2 and then compresses its volume through the inner conical surface 3. Furthermore, the flow velocity of the gas-liquid mixture is increased. When the gas-liquid mixture enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com