Gas production system for water-gas well

A water-gas and steam-water separator technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of easy safety accidents and low safety reliability, so as to improve the atomization effect and avoid impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

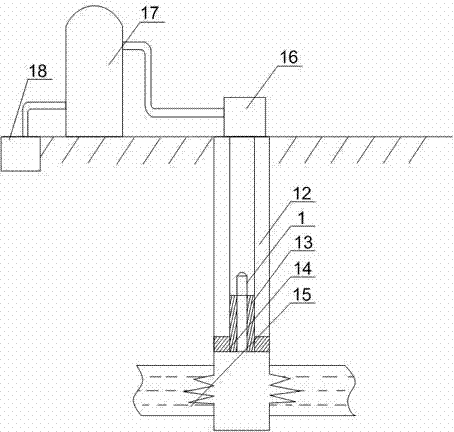

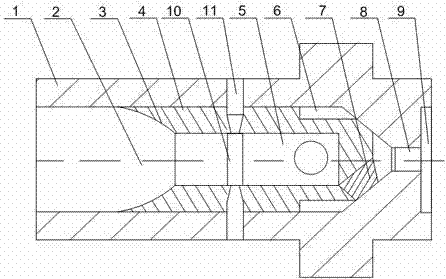

[0023] Such as Figure 1~4 As shown, this embodiment includes a packer 14 and a fixed cylinder 13 fixed in the casing 12, and the upper end of the casing 12 is sequentially connected with a pre-storage chamber 16, a steam-water separator 17 and a water pool 18. A nozzle is threadedly connected to the fixed cylinder 13, wherein the nozzle includes a nozzle inner core 4 and a nozzle shell 1 sleeved outside the nozzle inner core 4. The end of the nozzle shell 1 is provided with a spray hole 8, and inside the nozzle One end of the core 4 is provided with an inner conical surface 3, and the inner conical surface 3 and the inner wall of the nozzle shell 1 form an air intake cavity 2, and the other end of the nozzle inner core 4 has a through hole facing the jet hole 8, and the inner wall of the through hole A plurality of swirl vanes 7 are installed on it, and the through hole and the inner wall of the nozzle inner core 4 form a swirl cavity 5; it also includes two air holes 11 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com