Real-time electrostatic monitoring device for powder

A monitor and powder technology, which is applied in the direction of instruments, measuring devices, and measuring electrical variables, can solve the problems of inability to accurately and real-time monitor the charge of powder materials and the limitation of powder range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

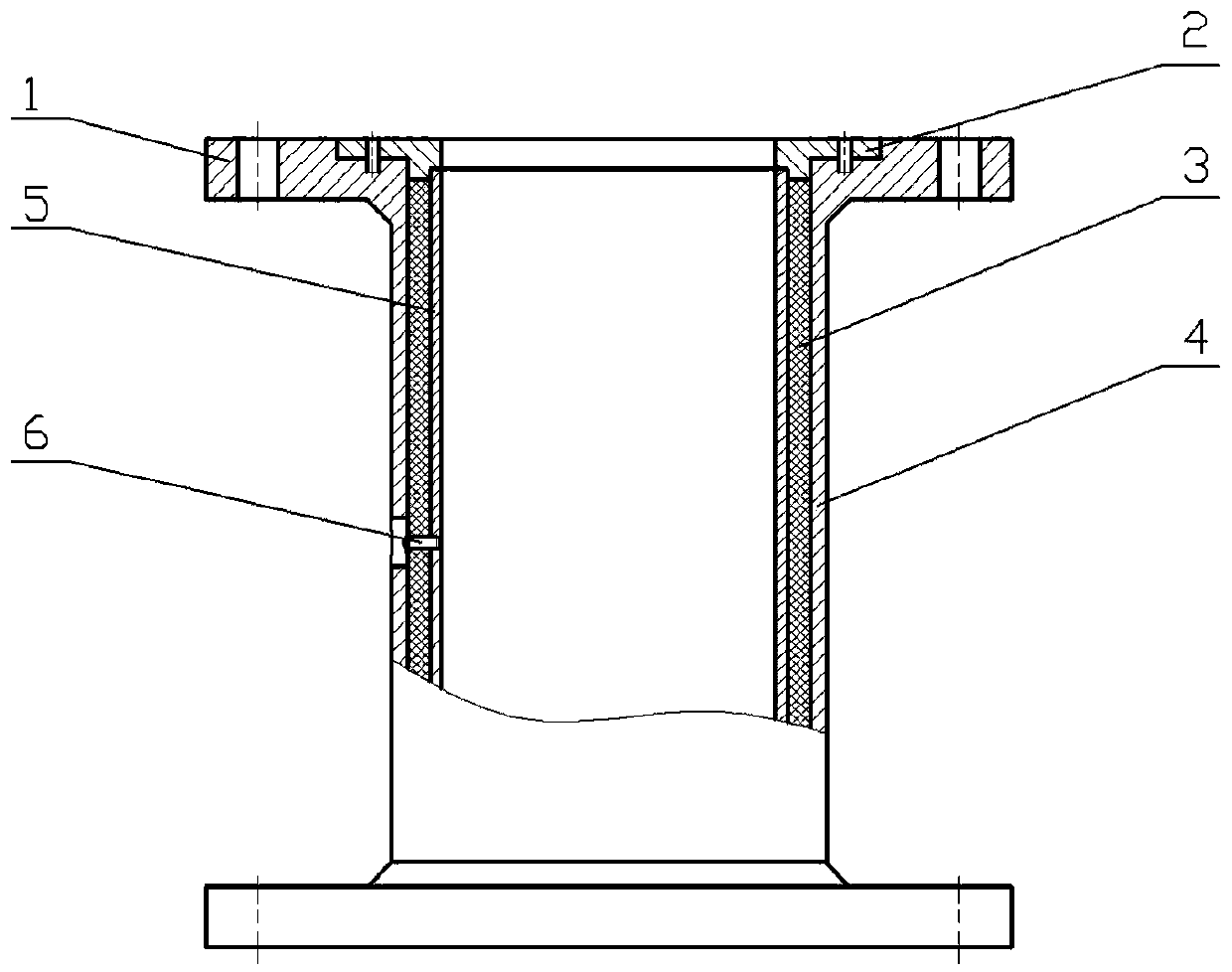

[0015] figure 1 It is the embodiment of the real-time online monitor for powder static electricity of the present invention. The device adopts the principle of Faraday cylinder for real-time electrostatic monitoring of powder materials. Specifically, a section of the conveying cylinder is used as a monitor as a whole. The device includes a metal inner cylinder 5 in contact with the powder material, which is concentrically arranged with the metal inner cylinder 5 The metal outer cylinder, and the insulating layer 3 arranged between the inner and outer cylinders, at least one position of the insulating layer 3 is provided with a point connection device 6, one end of which is connected to the metal inner cylinder 5, and the other end protrudes from the insulating layer 3 and is exposed to the metal In the opening on the wall of the outer cylinder 4. The device is installed on the pipeline close to the feed of the silo, and the inner diameter is consistent with the inner diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com