Sanitary line attachment

A connection and pipeline technology, applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, passing through components, etc., can solve problems such as non-installation, error, user neglect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

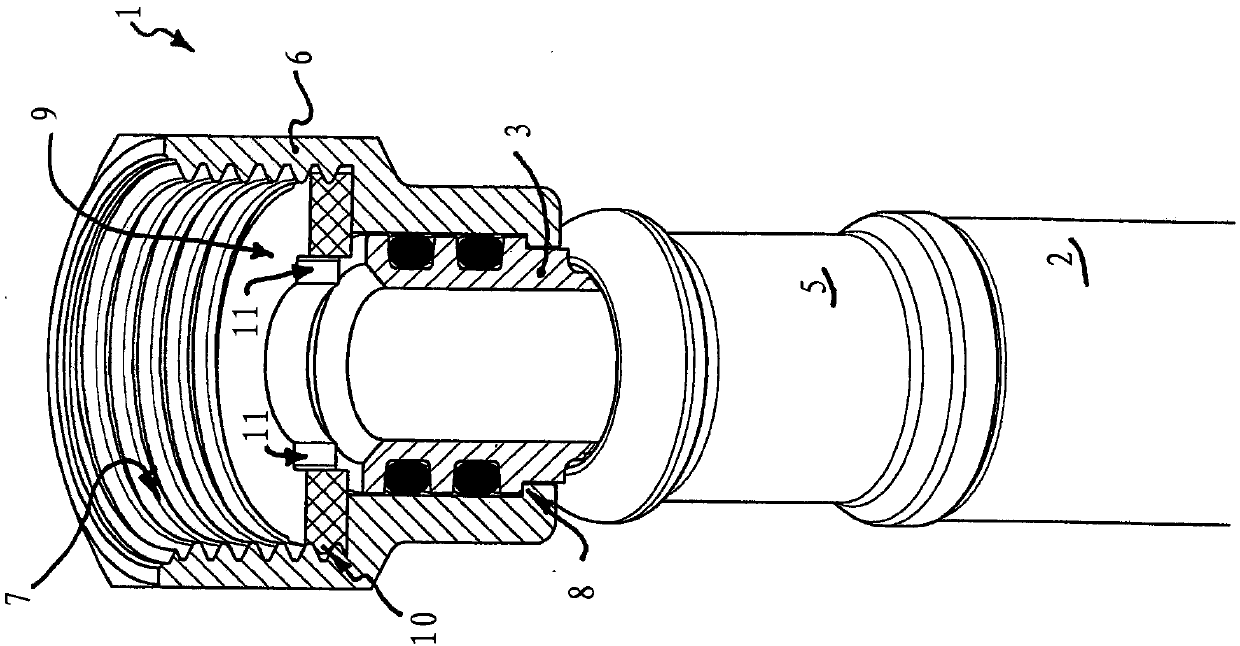

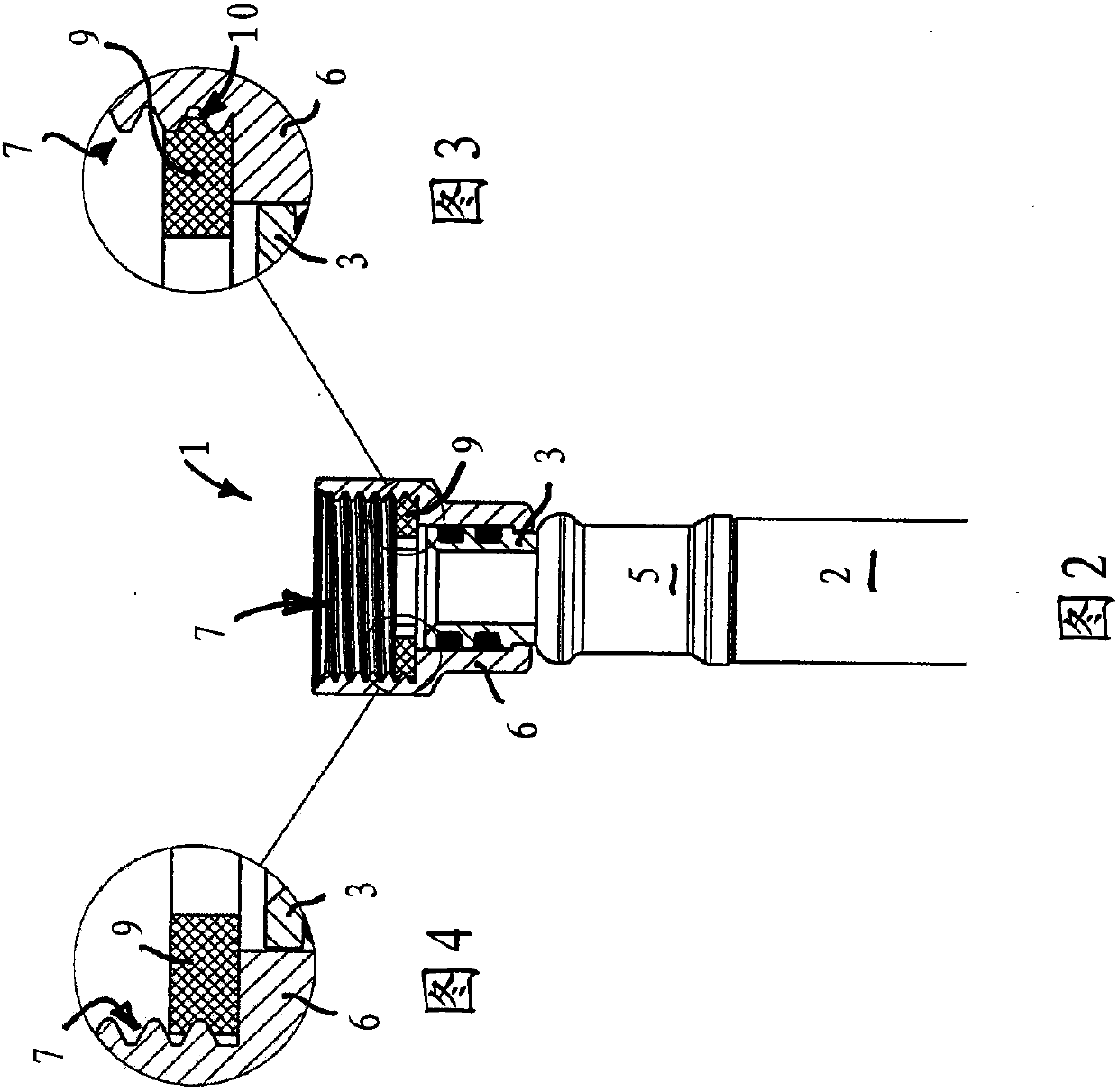

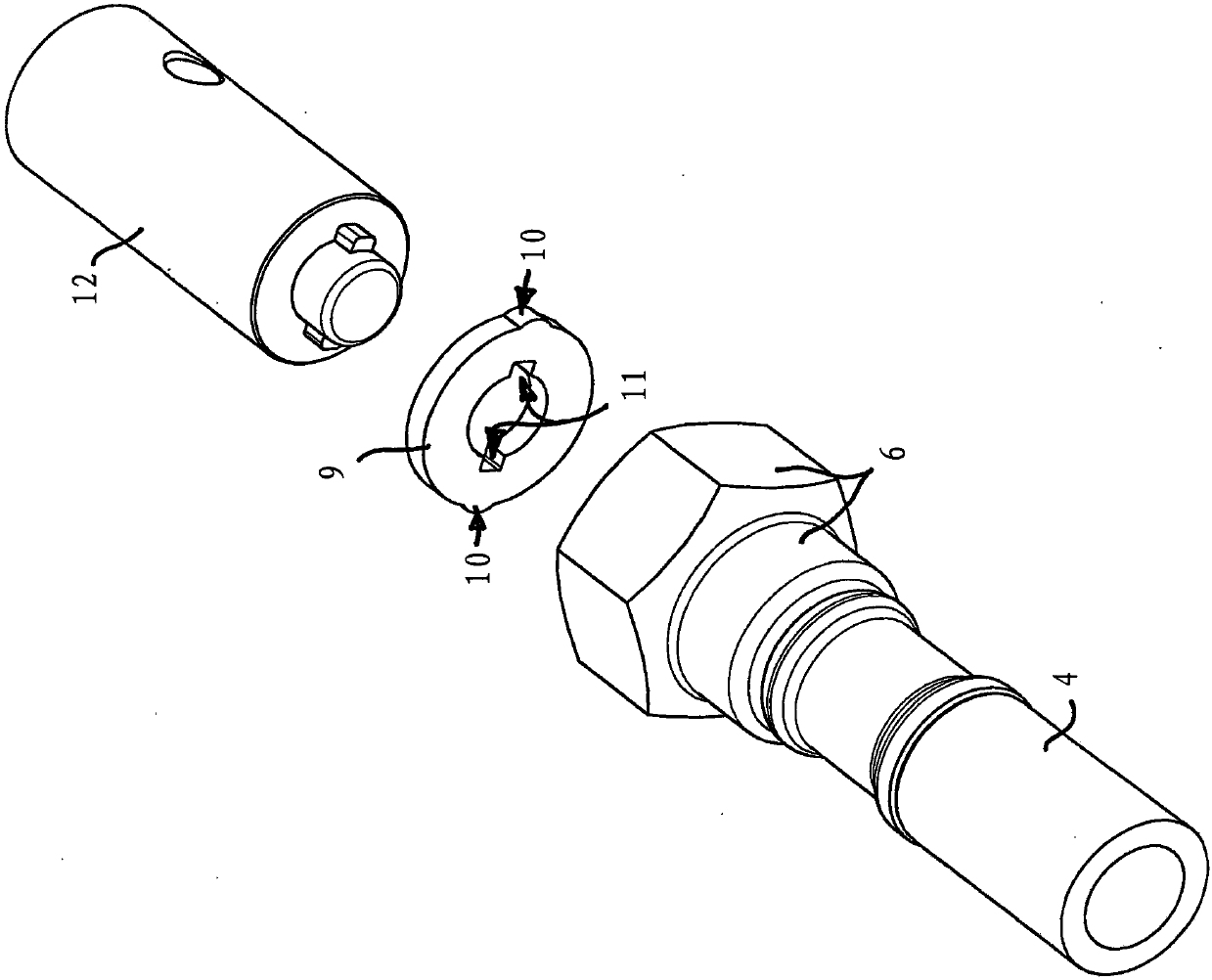

[0022] Figure 1 to Figure 3 A sanitary line connection 1 is shown, which is designed here as a hose connection for a flexible water hose 2 . The line connection 1 comprises a pipe connection 3 with a nipple 4 onto which one of the hose ends of the flexible hose is slipped. The hose end is held on the nipple 4 by a crimped crimp sleeve 5 which surrounds the hose end of the water hose 2 .

[0023] The line connector 1 shown here comprises a sleeve-shaped end region 6 which is provided in its sleeve interior for connection to an adjacent line section (not shown further here). The internal thread 7. The sleeve-shaped end region 6 is here formed by a union nut. On its end region facing away from the internal thread 7, the union nut engages from behind an annular shoulder 8 arranged on the pipe connection 3 in such a way that the union nut is held on the pipe in an axially immovable manner, although rotatable. Connector 3.

[0024] In order to seal the interface between the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com