Supply assembly line for pump sleeve inner wall machining equipment

A processing equipment and assembly line technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency and heavy manual workload, and achieve the effects of convenient operation, improved production efficiency and reduced manual workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

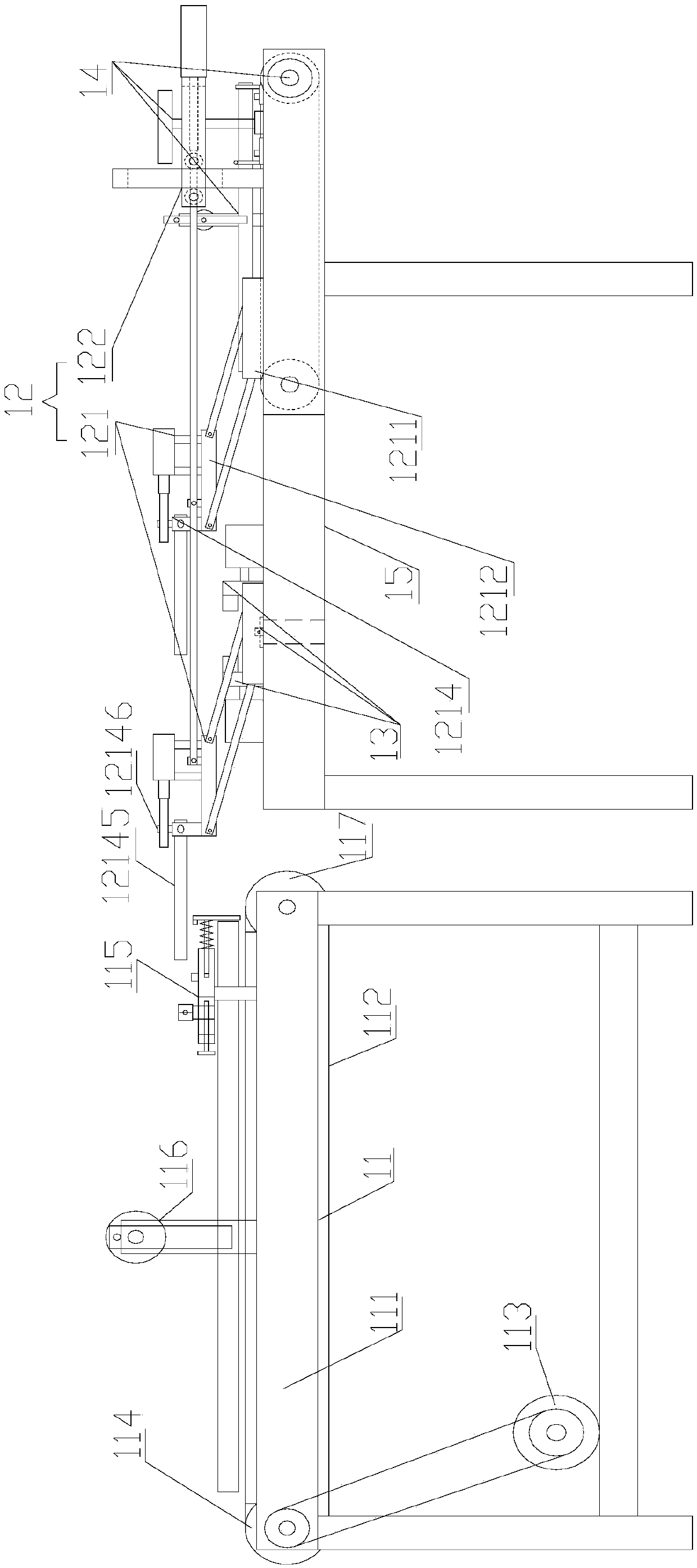

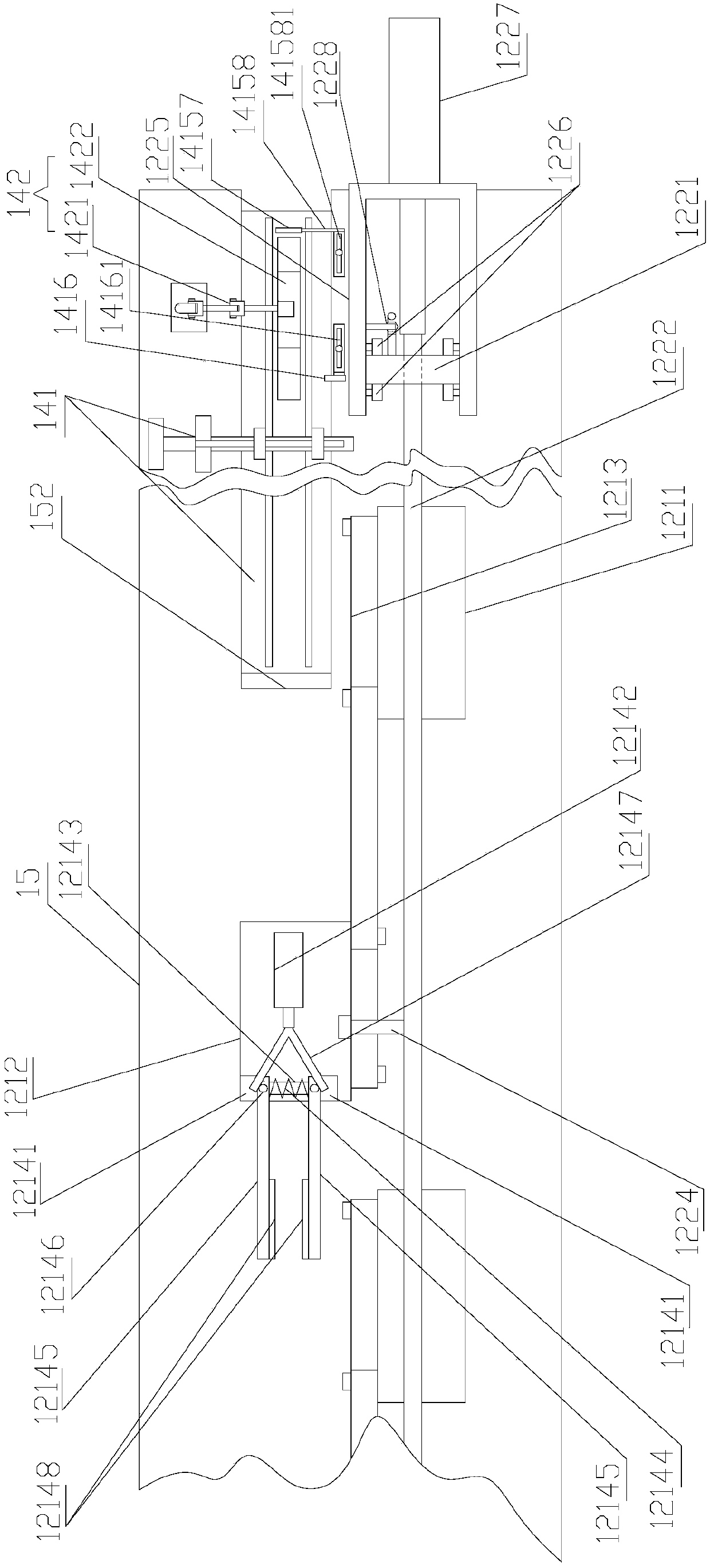

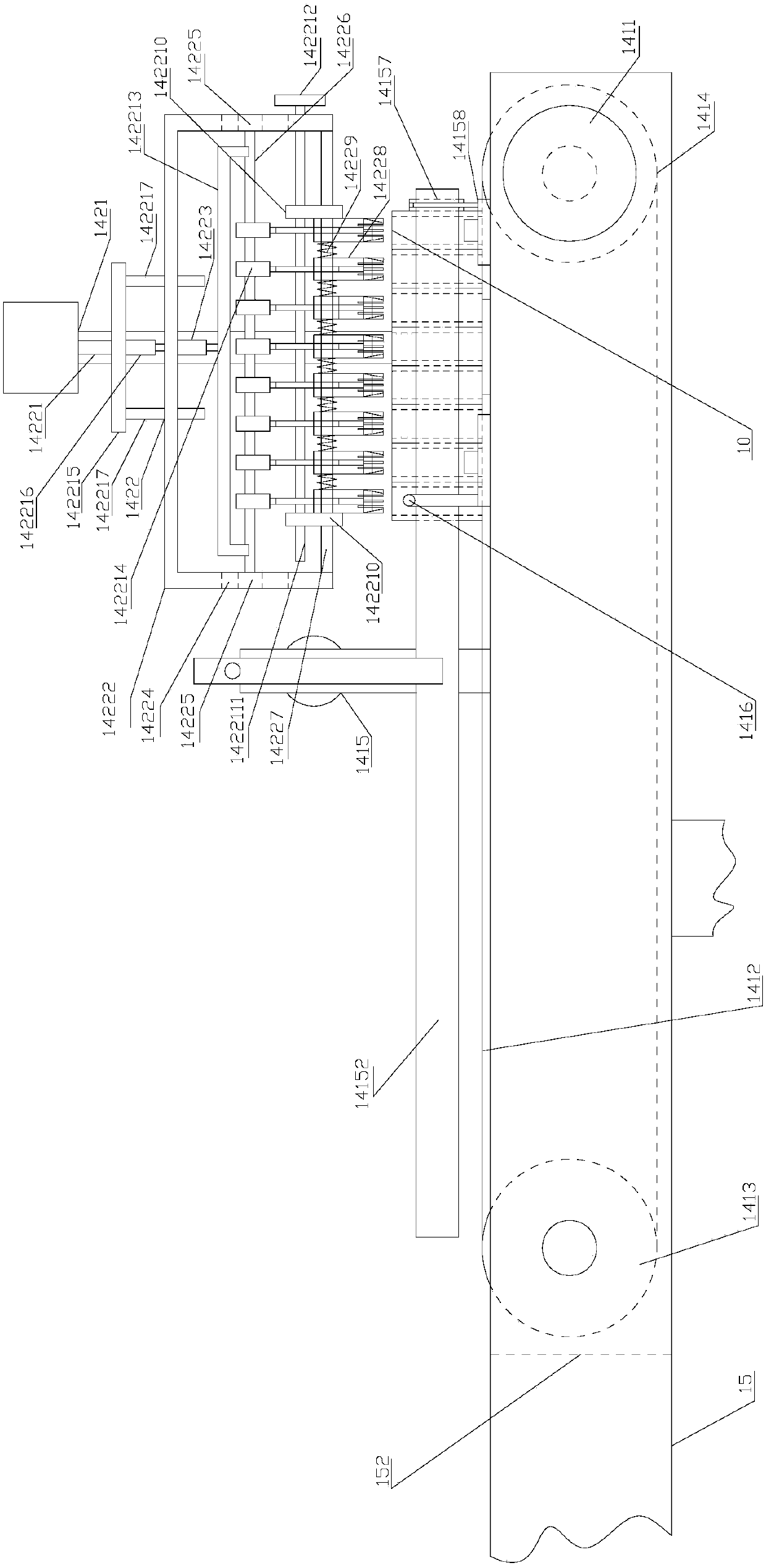

[0028] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11, the present invention is a feeding assembly line for pump sleeve inner wall processing equipment, including a material holding mechanism 11, a feeding mechanism 12, a fixing mechanism 13, a feeding device 14 and a frame body 15, and the front of the frame body 15 is provided with a material holding mechanism 11. The workbench of the frame body 15 is provided with a feeding mechanism 12, a fixing mechanism 13 and a feeding device 14, and the feeding mechanism 12 sends the pump sleeves 10 to be processed arranged on the storage mechanism 11 to the fixing mechanism 13, At the same time, the feeding mechanism 12 will take out the pump sleeve 10 processed on the fixing mechanism 13 and send it to the unloading device 14. The feeding mechanism 12 includes two forward and backward conveying mechanisms 121 and a driving mechanism...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap