Washing machine outer tub and washing machine

A technology of washing machine and outer tub, which is applied in the field of washing machines, can solve the problems of water flow throwing out safety hazards and affecting the effect of spraying, and achieve the effects of low cost, saving space, and reducing R&D and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

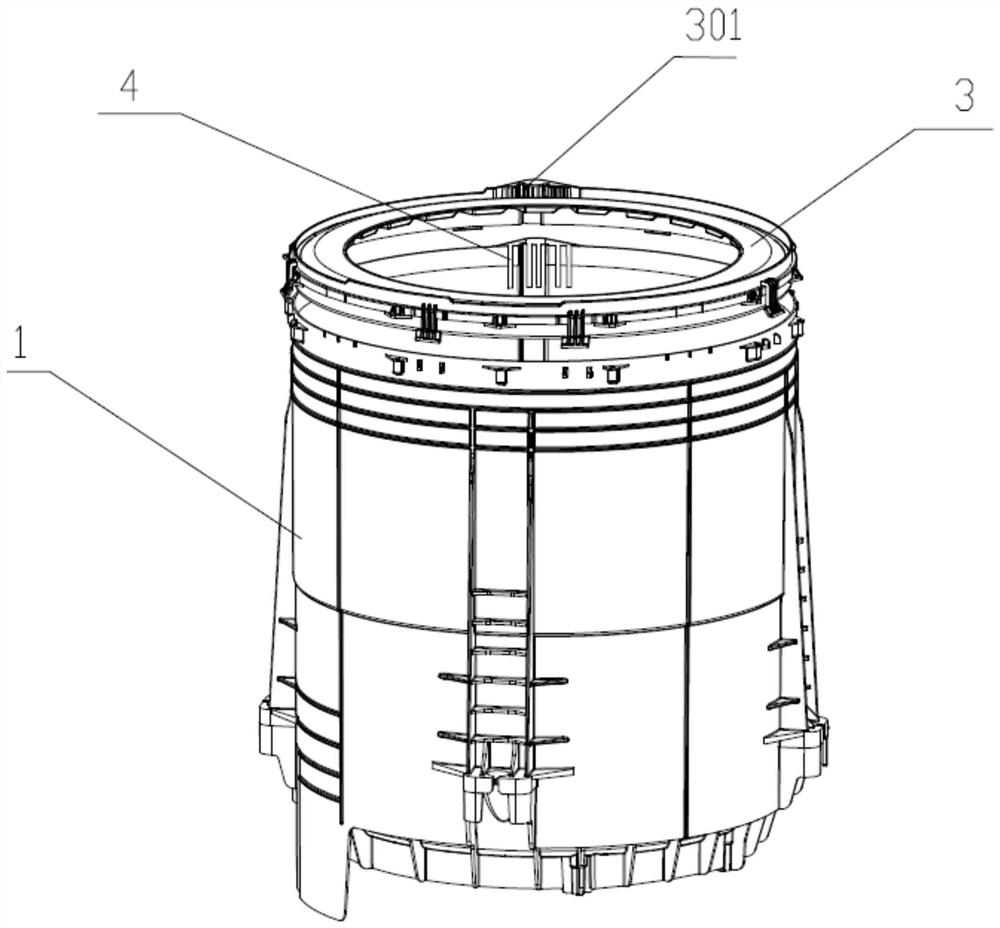

[0038] An outer tub of a washing machine, the upper part of which is provided with an overflow port 4, the inner wall of the outer tub 1 of the washing machine is provided with a water retaining rib 2 located below the overflow port 4, and the water retaining rib 2 extends from bottom to top to cover the overflow port 4 correspondingly. There is an overflow gap between 4 and the water retaining rib 2.

[0039] The water retaining ribs 2 are formed integrally with the inner wall of the outer tub 1 of the washing machine or are detachably connected.

[0040] The upper edge of the water retaining rib 2 is not lower than the upper edge of the overflow port 4, and the length extending along the circumference of the outer tub 1 of the washing machine is not shorter than the length of the overflow port 4;

[0041] Preferably, the lower edge of the water retaining rib 2 is integrally formed with the inner wall of the outer tub 1 of the washing machine, and the upper edge and both side...

Embodiment 2

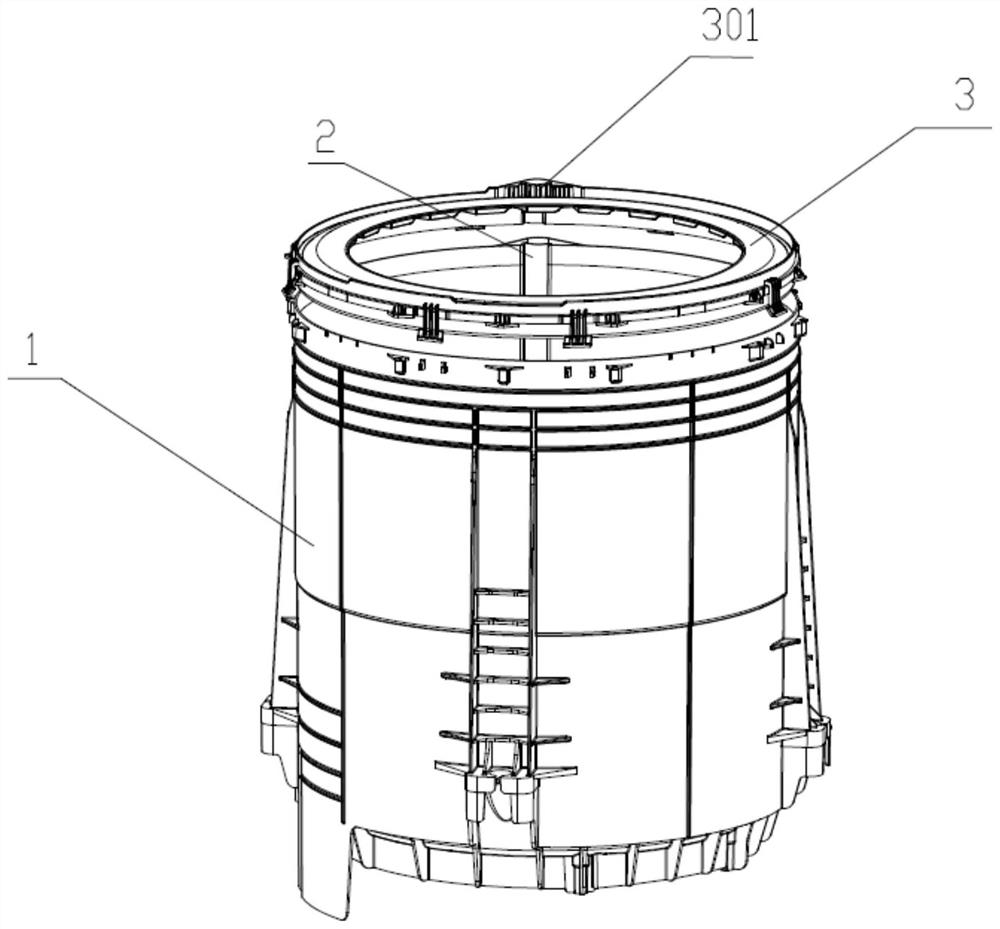

[0054] An outer tub 1 of a washing machine includes an overflow port 4 on the upper part, and a water retaining rib 2 extending from bottom to top to block the overflow port 4 is provided on the inner wall of the lower part corresponding to the overflow port 4 .

[0055] The water retaining ribs 2 are formed integrally with the inner wall of the outer tub 1 of the washing machine or are detachably connected.

[0056] Water retaining ribs 2 are arranged on the inner wall of the outer tub 1 of the washing machine to effectively prevent water from overflowing to the outside when the washing machine is in normal operating states such as spray washing or dehydration. The water retaining rib 2 is arranged on the inner wall of the washing machine outer tub 1, which can avoid increasing the development cost of the washing machine on the one hand, and does not need to expand the volume of the washing machine outer tub or other parts (such as the outer tub cover) of the washing machine. ...

Embodiment 3

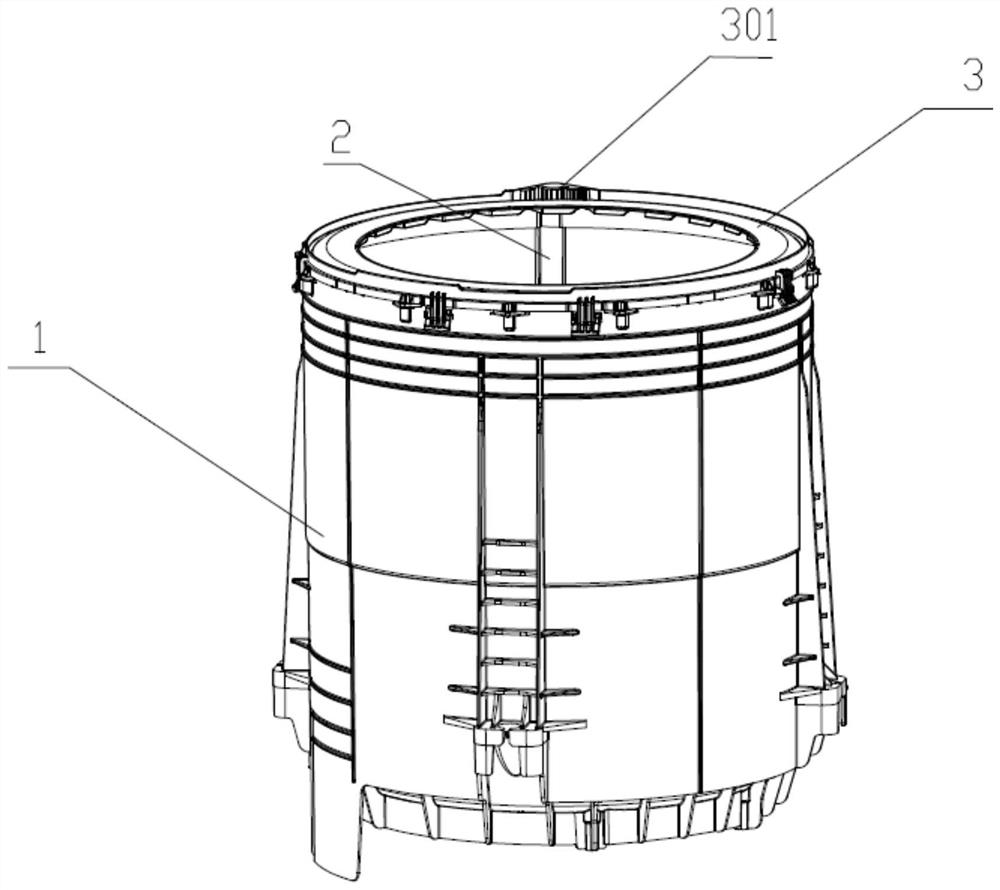

[0077] The difference between this embodiment and the second embodiment is that: on the basis of the basic idea of the second embodiment, the outer tub lid 3 of the washing machine is more optimally designed.

[0078] The outer barrel cover 3 includes an upper cover body and a lower cover body, the upper cover body and the lower cover body are connected to form a water cavity, the outer barrel cover 3 has a water inlet, and the upper part of the outer barrel cover 3 is provided with an overflow protection structure 301, and the overflow protection structure 301 directs the overflowing water in the water chamber to the outside of the outer bucket. The overflow protection structure 301 can guide the abnormal water inflow and overflow water in the water chamber to the part between the outer tub and the washing machine box without electrical components in a directional manner.

[0079] The overflow protection structure 301 is a drain hole arranged on the upper cover and communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com