A platform for vertical milling machine processing

A vertical milling machine and platform technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of easy oil leakage, poor processing performance, etc., to facilitate flexible installation and disassembly, purify the production environment, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

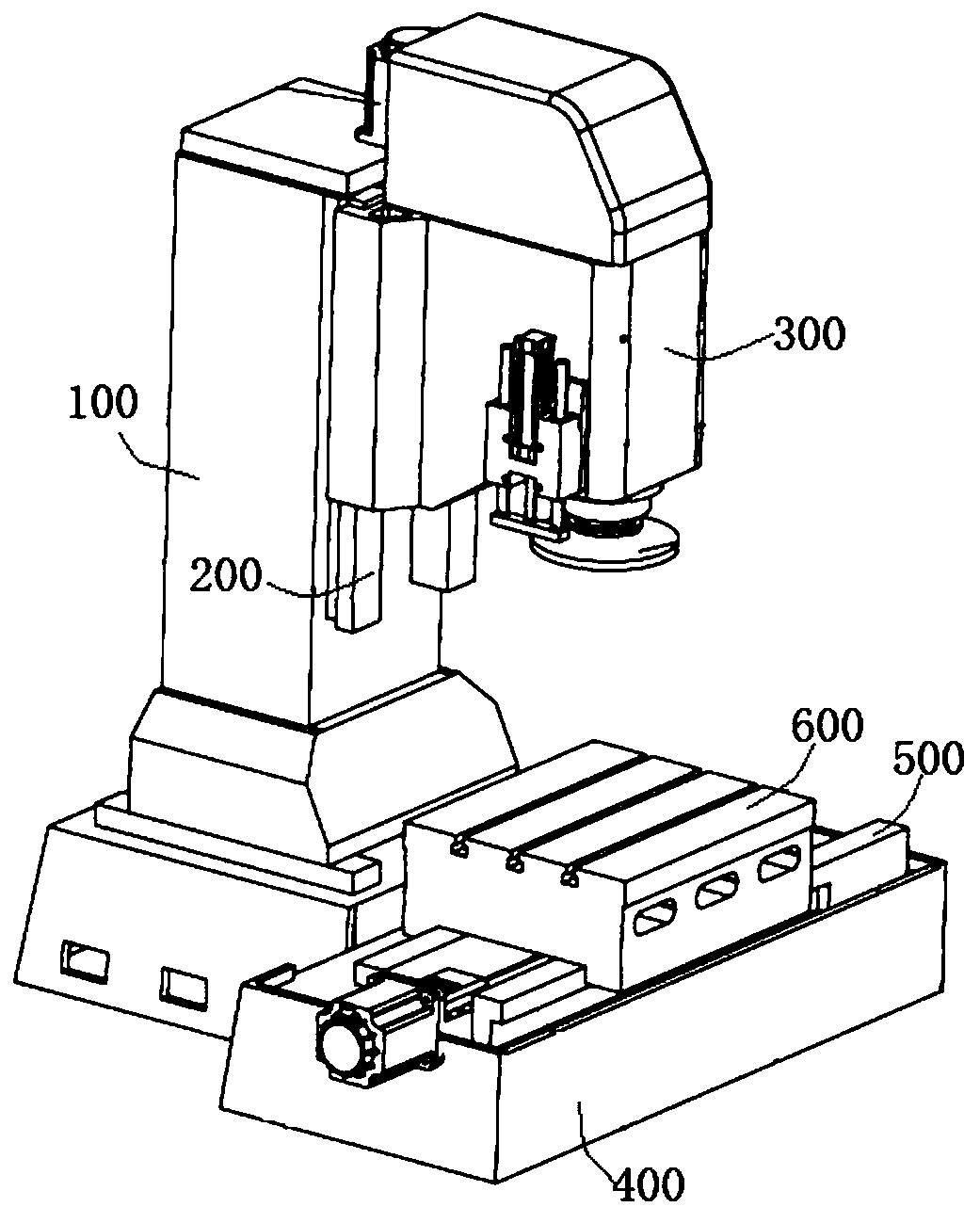

[0041] Such as Figure 1-Figure 6 As shown, the overall structure of the CNC vertical milling machine in this embodiment is as follows figure 1As shown, it includes a bed unit 400 arranged horizontally, a column unit 100 is longitudinally arranged on one side of the bed unit 400, a vertical slide rail unit 200 is arranged on the column unit 100 along the height direction, and a machine The head unit 300, driven by the power mechanism, the head unit 300 can move vertically along the vertical slide rail unit 200, wherein the lower end of the head unit 300 is provided with a milling cutter unit, and both sides of the bed unit 400 are provided with slide rails in parallel The unit 500 is slidingly fitted with a workbench unit 600 on the slide rail unit 500; a horizontal drive unit is also arranged on the bed unit 400, and the horizontal drive unit is connected with the workbench unit 600 and is used to drive the workbench unit 600 along the slide rail The extension direction of t...

Embodiment 2

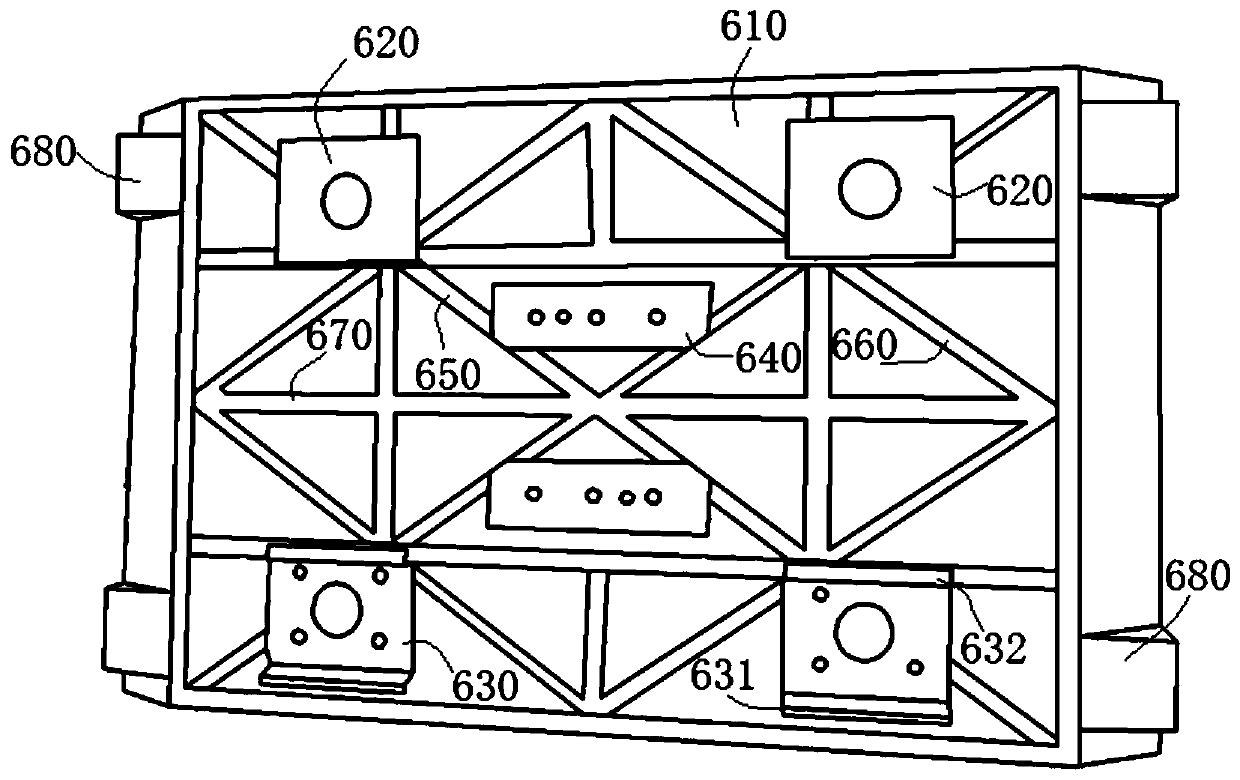

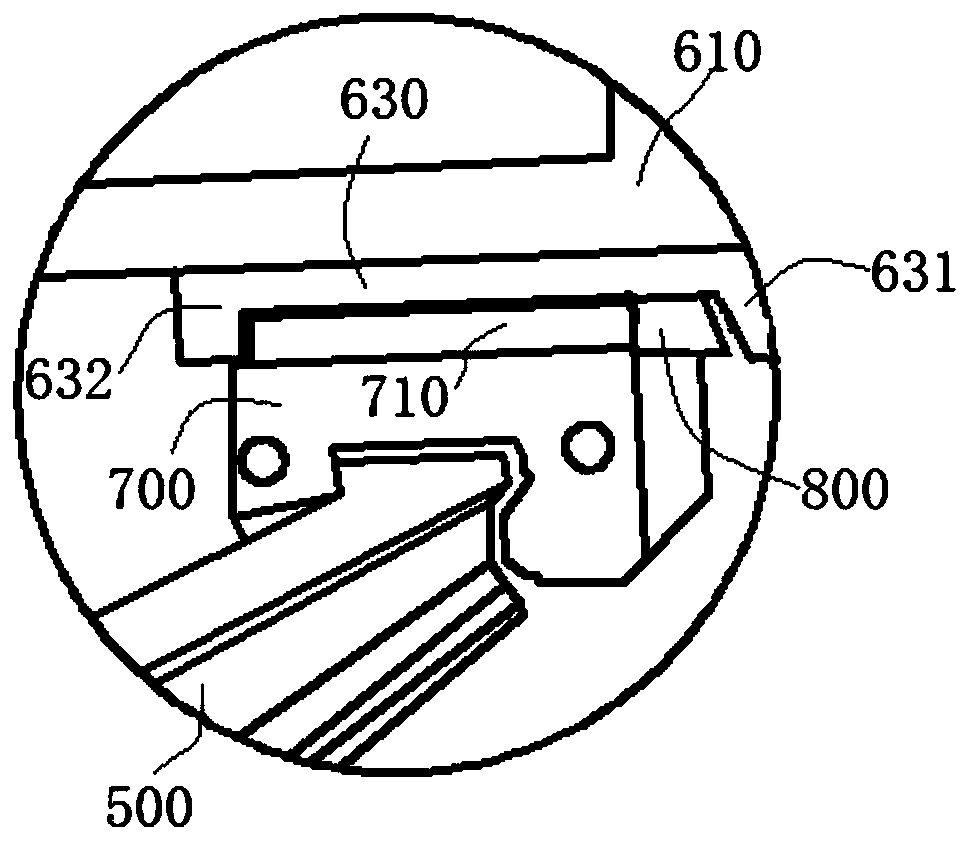

[0047] A kind of platform that is used for vertical milling machine processing of this embodiment, basic structure is the same as embodiment 1, further, as figure 2 with image 3 As shown, the workbench unit 600 in this embodiment includes a workbench body 610, and both sides of the bottom of the workbench unit 600 (ie, the bottom of the workbench body 610) are provided with a driven slider 620 and a driving slider 630 in parallel, and the slide rail unit 500 The sliding seat 700 is arranged on the upper slide, and the top of the sliding seat 700 is provided with a protruding matching block 710. The driven slider 620 and the driving slider 630 are respectively matched with the matching blocks 710 on both sides. Specifically, from Both the movable slider 620 and the active slider 630 include a panel attached to the mating block 710 on a plane, and the two sides of the active slider 630 are also provided with an outer clamping plate 631 and an inner clamping plate 632 for later...

Embodiment 3

[0052] A platform for processing by a vertical milling machine in this embodiment has the same basic structure as in Embodiment 1. Furthermore, in this embodiment, the two side walls of the slide rail unit 500 are side rail structures with a concave center and convex sides. Such as figure 2 As shown, the bottom of the sliding seat 700 is provided with a sliding cavity that matches the side rail, and the sides of the sliding cavity and the side rail slide through balls, and the setting of the side rail effectively ensures that the sliding seat 700 and the sliding rail unit 500 The matching accuracy ensures the stability and direction accuracy of the slide seat 700, thereby ensuring the processing accuracy of the product and the processing quality; specifically, as image 3As shown, the two side walls of the slide rail unit 500 respectively include a central straight section 550 located in the middle, and the central straight section 550 is a straight side wall located on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com