Working method for semi-automatic detecting fixture for signal lamp

A technology for detecting tooling and working methods, which is applied in sorting and other directions, can solve the problems of unqualified products mixed, wrong sorting, complex structure, etc., and achieve the effect of facilitating batch testing, avoiding classification errors, and convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

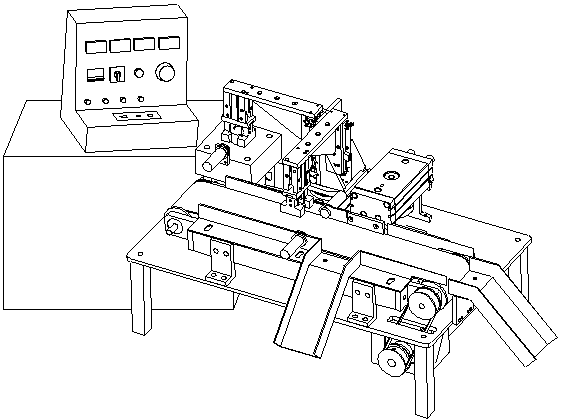

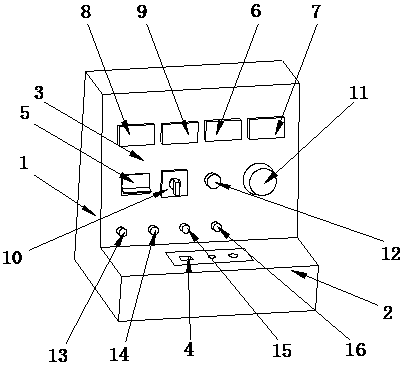

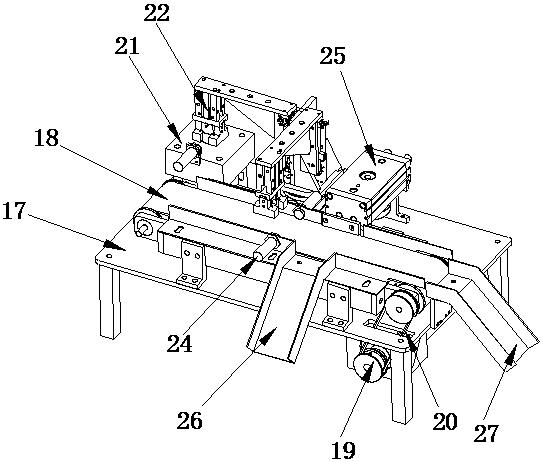

[0018] Such as Figure 1 to Figure 4 , the present invention relates to a working method of a semi-automatic detection tool for a signal lamp. The semi-automatic detection tool for a signal light used in the working method includes a detection device 1 and a conveying device 17. The detection device 1 is composed of a detection table 2 and a button table 3. , where a plurality of detection holes 4 of different sizes are opened on the detection platform 2, and the plurality of detection holes 4 are used to detect signal lamps of different specifications, and a power switch 5, a DC voltmeter 6, a DC ammeter 7. AC voltmeter 8, AC ammeter 9, AC-DC switch 10, voltage regulator 11 and signal source acquisition button 12, the power switch 5 is used to supply power to the instrument in the button table 3, and the DC voltmeter 6 , DC ammeter 7, AC voltmeter 8, AC ammeter 9, and voltage regulator 11 are installed in the body 1, and only the display screen and the knob are exposed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com