Vehicle fastener online detection method

A detection method and fastener technology, applied in the field of vehicle fastener online detection system and vehicle fastener online detection, can solve the problems of low degree of detection automation, poor consistency of detection results, lack of perfect detection system, etc. Achieve the effect of reducing manual interference, ensuring uniform testing standards, and meeting the needs of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

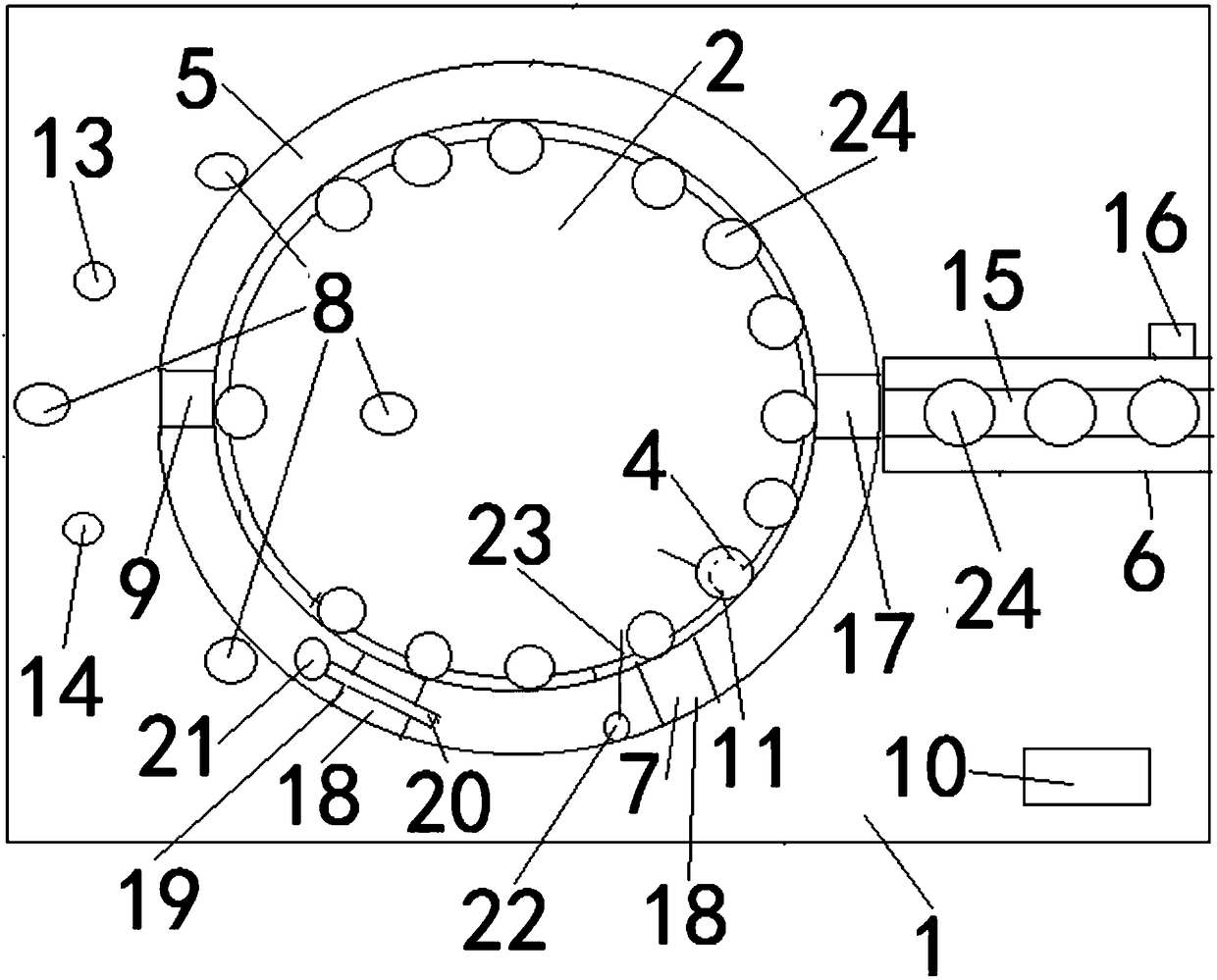

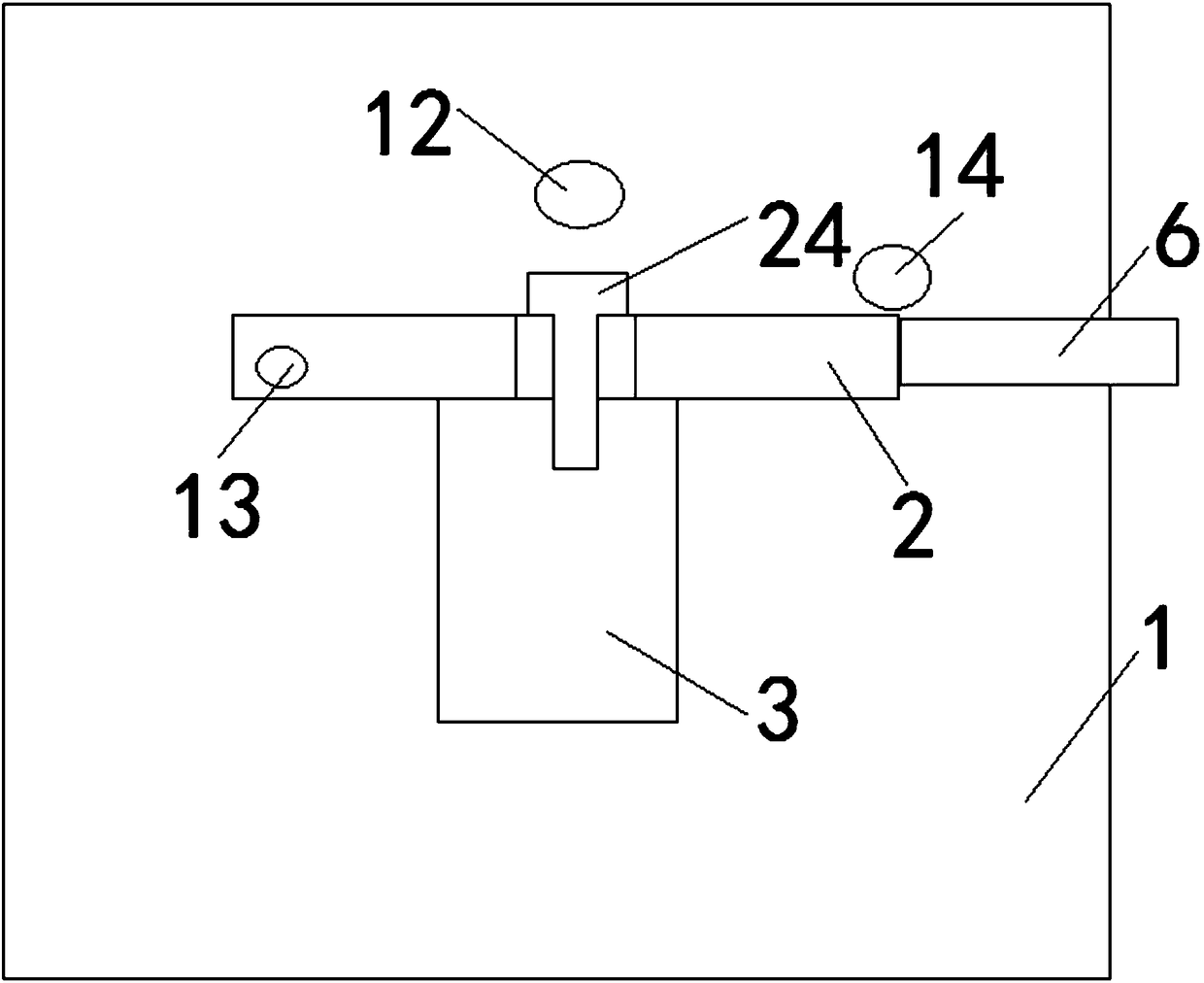

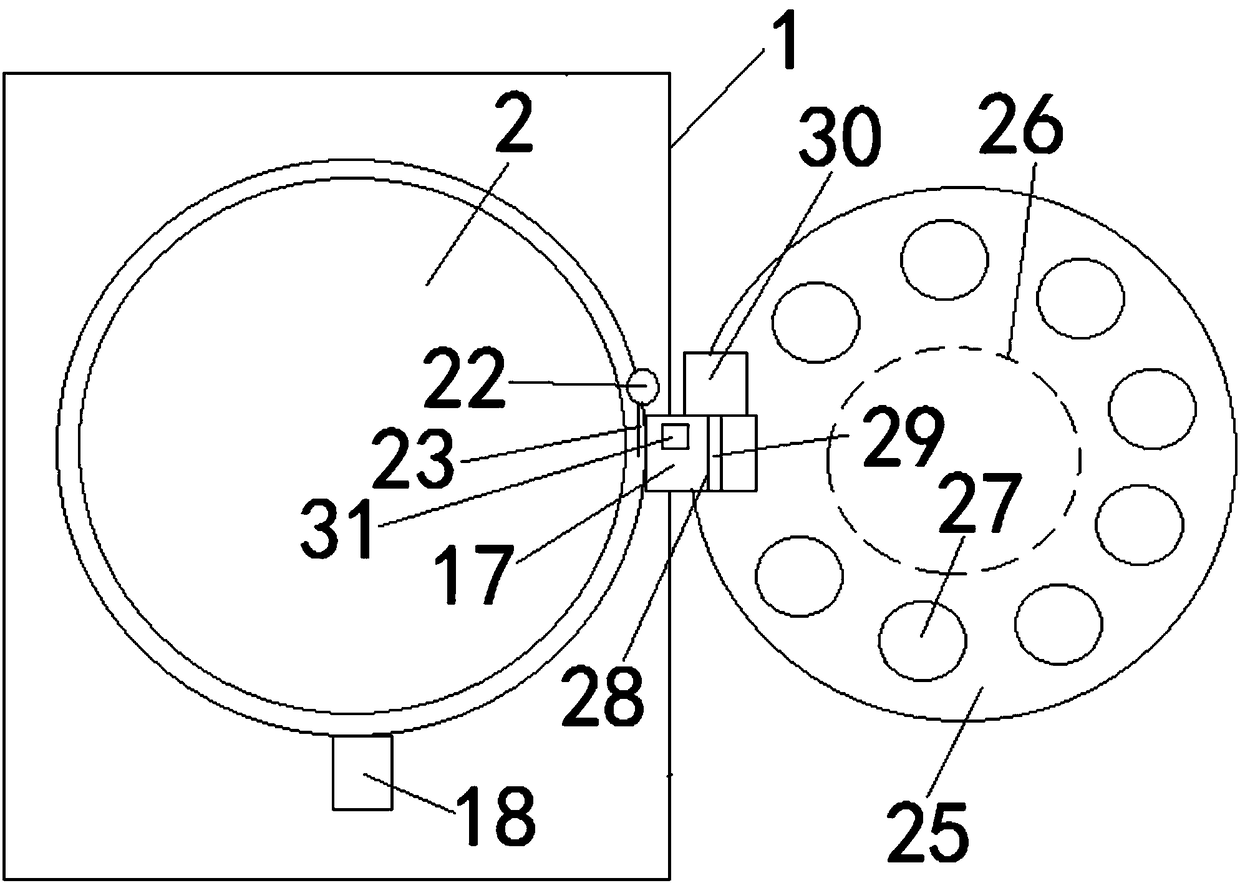

[0029] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

[0030] as attached figure 1 - attached image 3 As shown, the present invention is an on-line inspection system for vehicle fasteners. The on-line inspection system for vehicle fasteners includes a system frame 1 on which a fastener delivery tray 2 and a limit position are set. The ring 5, the fastener conveying tray 2 is connected to the conveying tray drive motor 3, the conveying tray driving motor 3 is connected to the control part 10, and the outer ring of the fastener conveying tray 2 is provided with a plurality of fastener slots 4 arranged according to gaps, The outer ring of the fastener conveying tray 2 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com