Automatic release paper tearing equipment

A technology of release paper and equipment, which is applied in the field of automatic tear-off paper equipment, can solve problems such as low production efficiency, uncoordinated supply relationship, and low degree of automation, and achieve the goals of reducing labor force, solving tense supply relationship, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

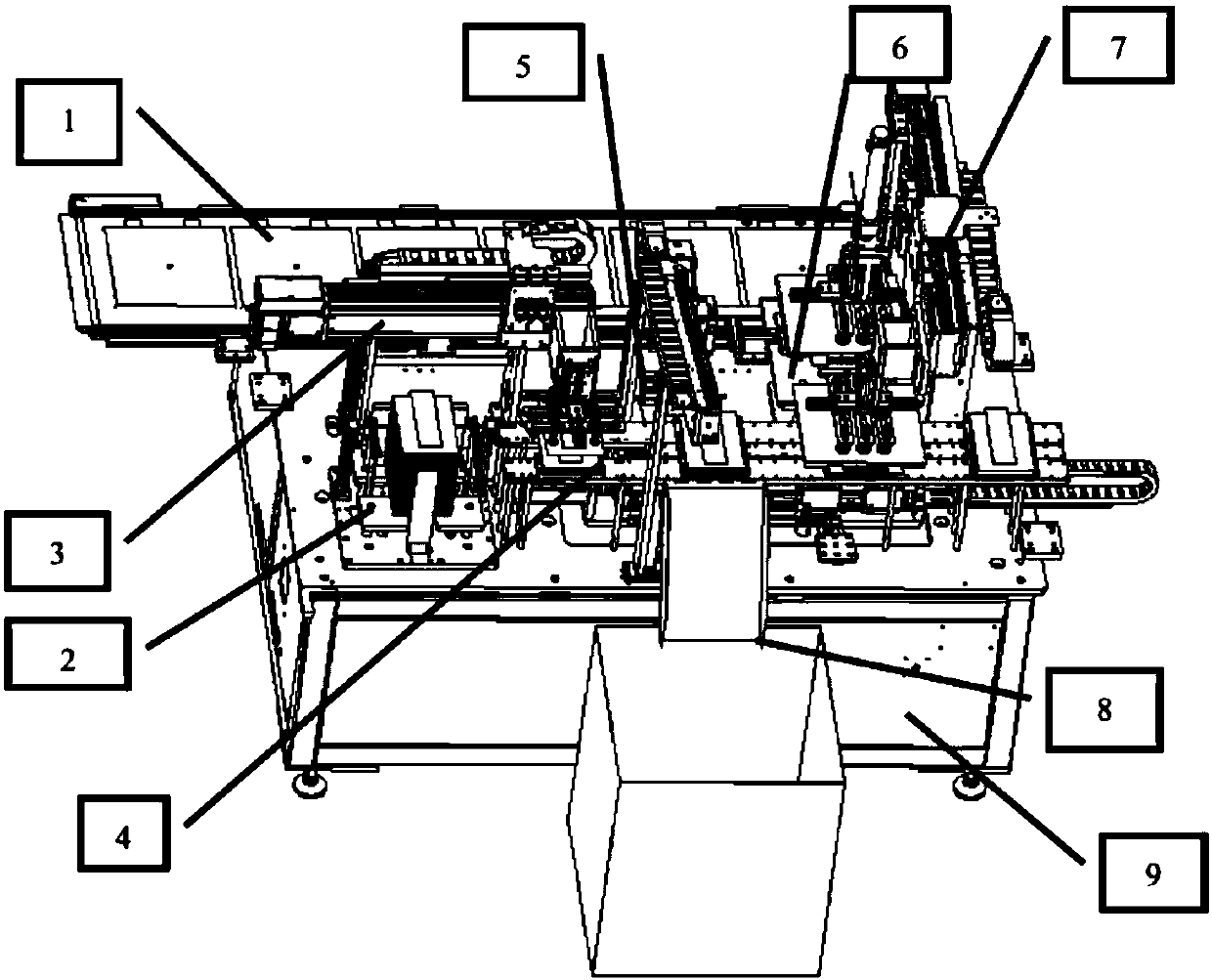

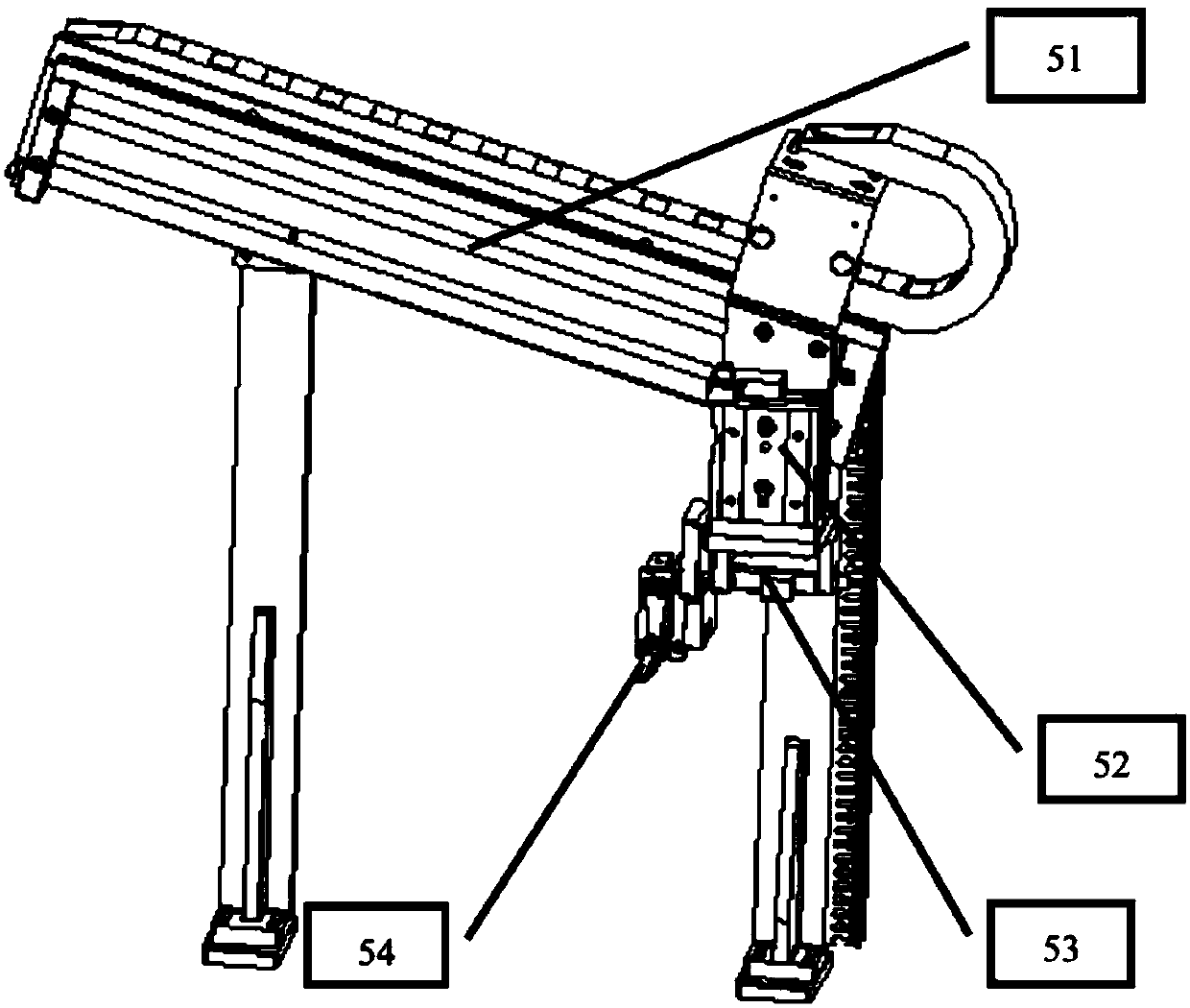

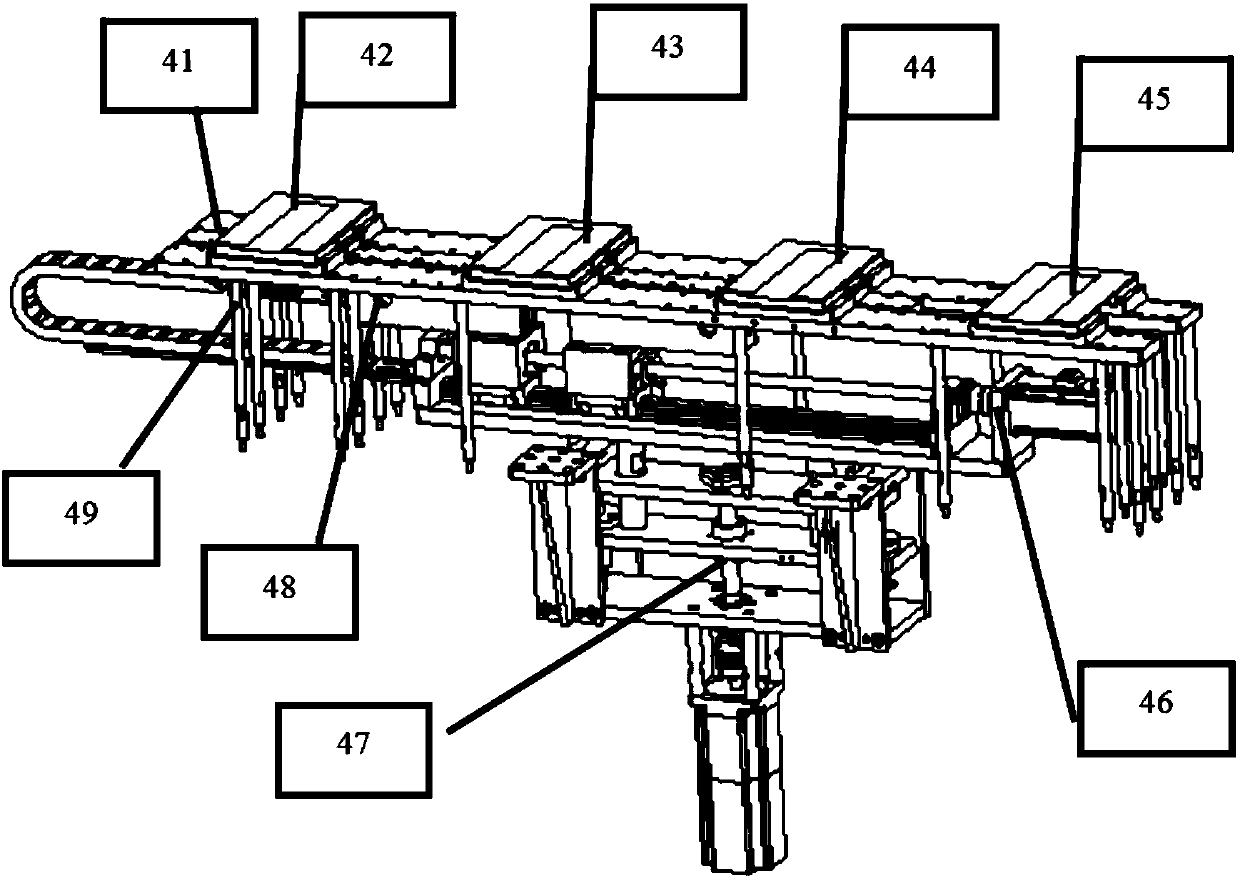

[0027] refer to Figure 1-8 , the present invention provides an automatic tear-off type paper device 5, the automatic tear-off type paper device 5 is assembled on the first frame 9, including: a rodless cylinder 51, a Z-axis sliding table cylinder 52, and an X-axis sliding table cylinder 53 and jaws 54; the rodless cylinder 51 and the sheet material 21 release paper tearing off the moving path are set at a separation angle; the jaws 54 are assembled on the bottom of the X-axis sliding table cylinder 53, and the X-axis sliding table cylinder 53 is slidably assembled on the Z-axis sliding table cylinder 52, Z-axis sliding table cylinder 52 is slidingly assembled on rodless cylinder 51; Z-axis sliding table cylinder 52 drives X-axis sliding table cylinder 53 and gripper 54 to move in the Z-axis direction, X-axis sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com