Gas-bath slow-cooling process and device for processing best excellent steel sheets

A technology of steel and air bath, which is applied in the field of air bath slow cooling device for super-high-quality steel processing, which can solve the problems of uneven cooling of steel, slow slow cooling speed, high cutting rate, etc., and achieve low cutting rate and improved slow cooling effect , Improve slow cooling effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

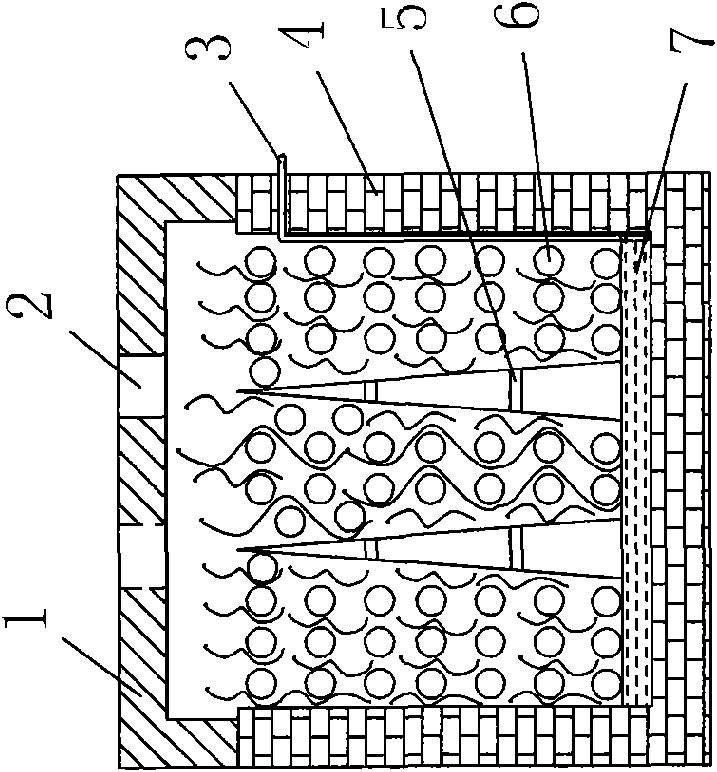

[0026] Example 1: Air-bath slow-cooling process for steel processing using structure 1 of the air-bath slow-cooling device: see figure 1 , at first add cold water to the bottom of slow cooling pit 4 by water inlet pipe 3, general water level is controlled at the 2 / 3 height of square steel horn 7, must not exceed square steel horn 7 at the most. Then high-temperature steel 6 (in bundles) is hoisted into the slow cooling pit 4 (placed on the square steel backing iron 7), covered with a thermal insulation cover 1, and passed through the water inlet pipe 3 to the bottom of the slow cooling pit 4 in a timely manner as required To replenish water, the cold water is vaporized by the temperature of the steel itself, forming an air bath for slow cooling, and the slow cooling pit can be lifted out in about 36 hours.

example 2

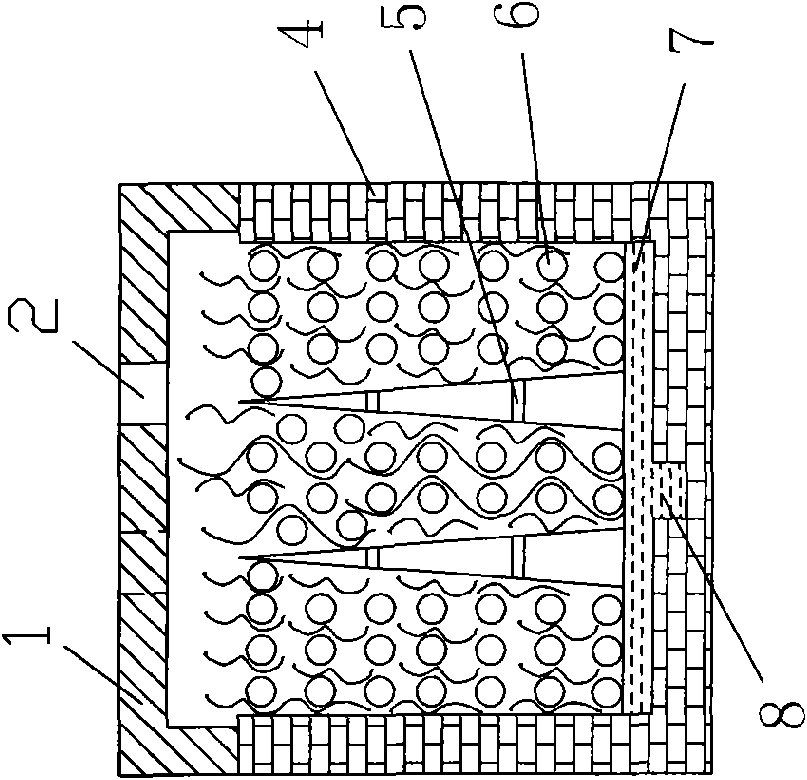

[0027] Example 2: Air-bath slow-cooling process for steel processing using the second structure of the air-bath slow-cooling device: see image 3 First, the high-temperature steel 6 (in bundles) is hoisted into the slow cooling pit 4 (placed on the square steel pad iron 7) and the heat preservation cover 1 is covered, and cold water is poured into the external inlet of the water storage tank 8, (the height of the cold water is not more than The height of water storage tank 8 gets final product), and observe water level, add water in right amount, make cold water gasification by the temperature of steel itself, form air bath slow cooling, about 38 hours, can hang out slow cooling pit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com