Inner cavity type hand wash basin

A wash basin and inner cavity technology, applied in the field of wash basins, can solve the problems that the wash basin does not have a water saving function and cannot clean equipment, etc., and achieves the effects of keeping the water flow quiet, preventing the water from spilling, and improving the practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

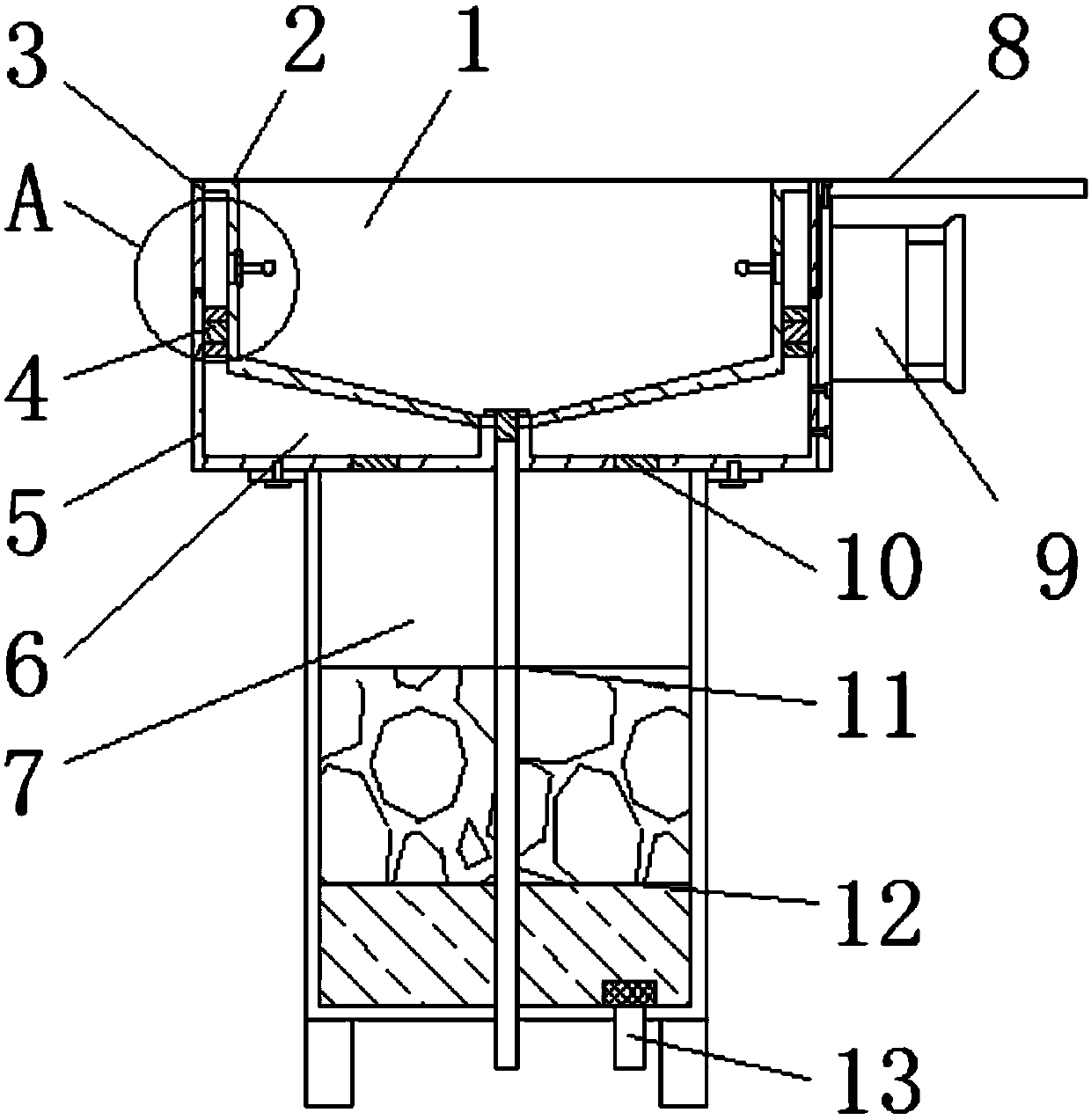

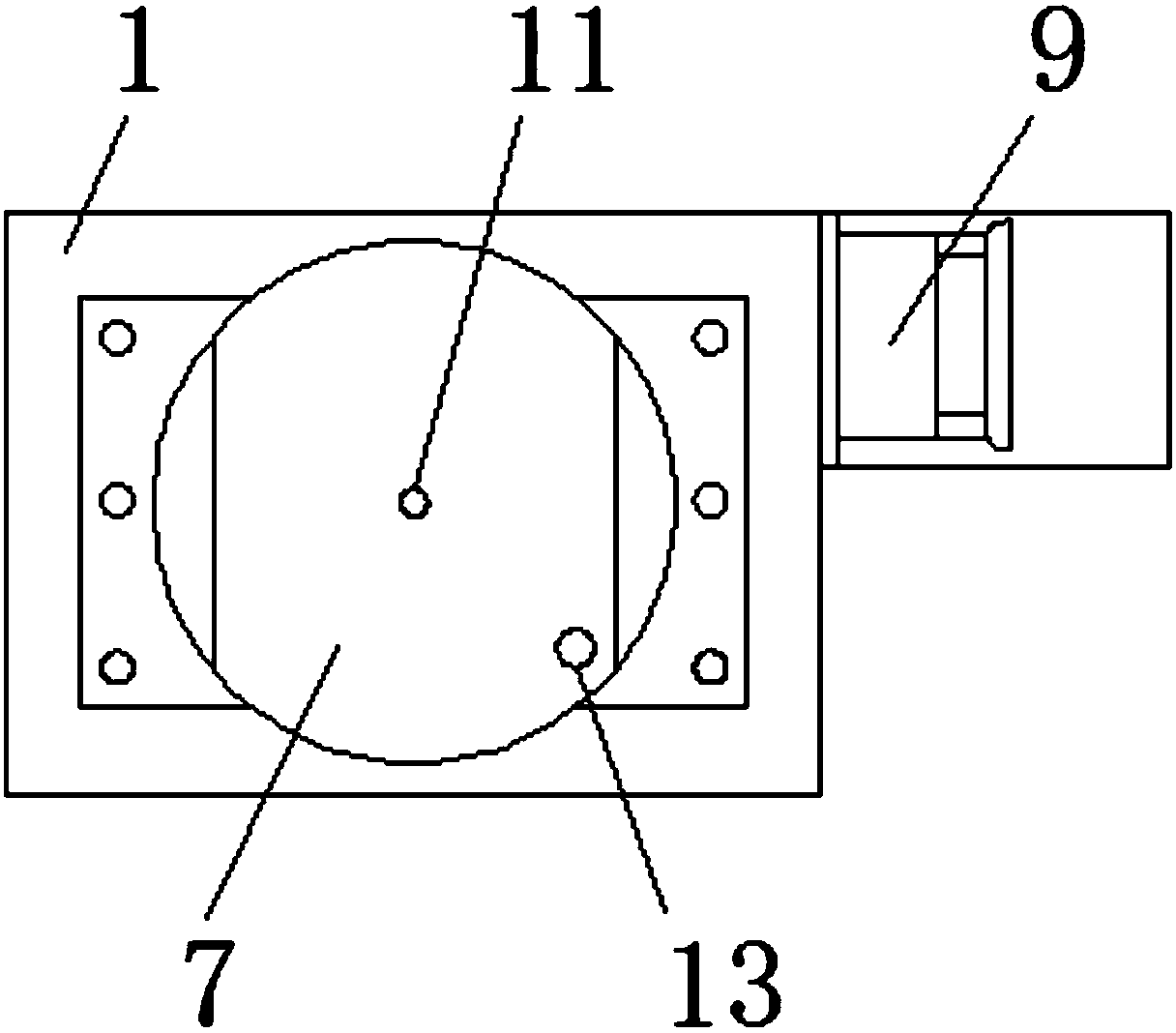

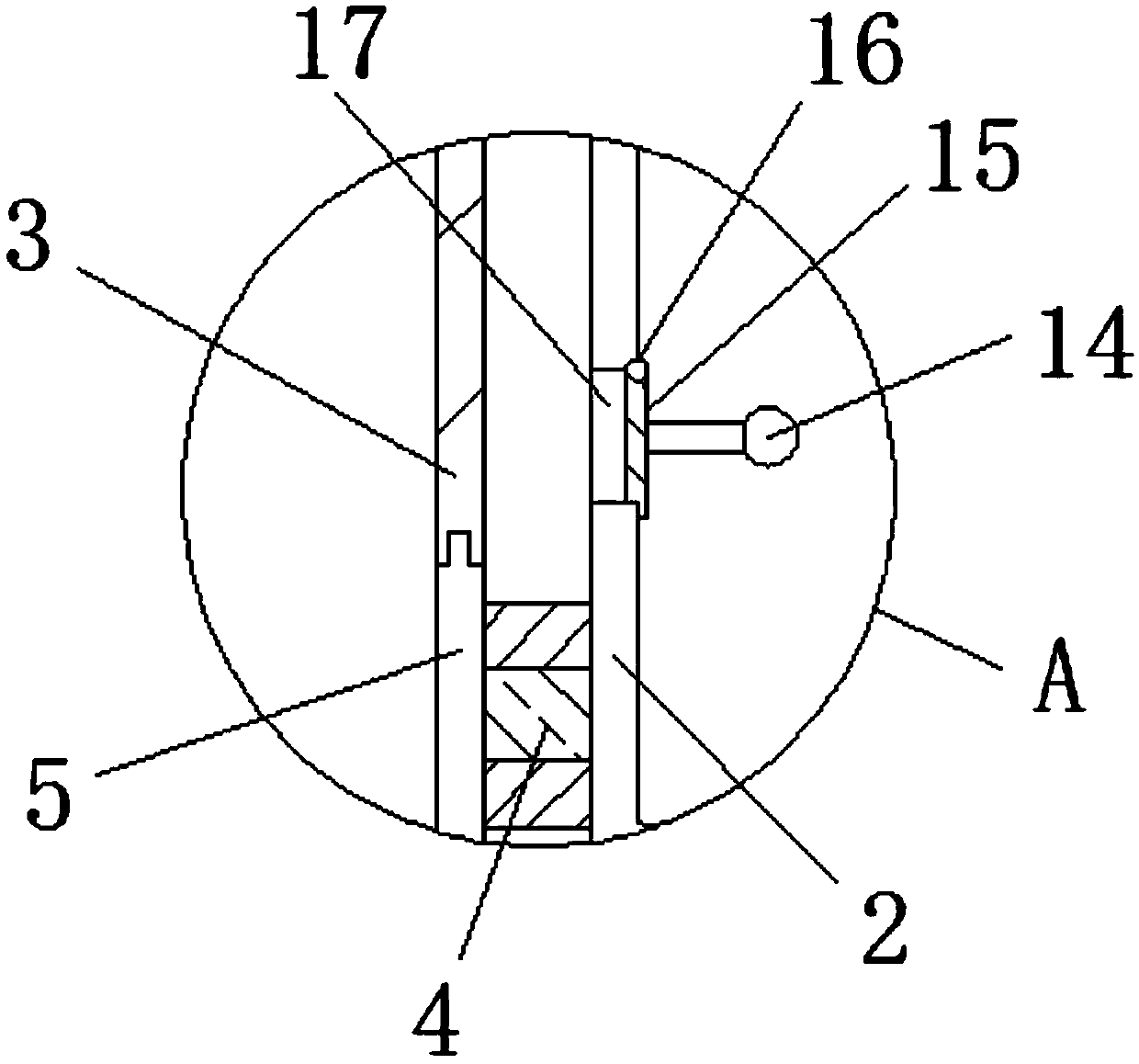

[0018] Such as Figure 1-Figure 3 As shown, a cavity-type washbasin mainly includes a washbasin 1, a fixed liner 2, a movable shell 3, a multi-stage filter layer 4, a fixed shell 5, a filter cavity 6, a water storage bucket 7, and a waterproof plate 8, hand dryer 9, water guide port 10, waste water discharge pipe 11, purification sedimentation layer 12, clean water discharge pipe 13, floating ball 14, baffle plate 15, rotating shaft 16 and water inlet 17, the outside of washbasin 1 is installed with fixed Inner tank 2, and a movable shell 3 is installed on the outside of the fixed inner tank 2, the upper surface of the fixed inner tank 2 is flush with the upper surface of the waterproof board 8, and the center line of the fixed inner tank 2 is in line with the center of the waste water discharge pipe 11 The lines coincide to facilitate the use of the equipment. The lower part of the movable housing 3 has a "concave" structure, and the upper part of the fixed housing 5 has a "c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com