Mutual Optimal Method of Indoor Mechanical Parameters and Rolling Construction Parameters of Rockfill Dam

A technology of mechanical parameters and construction parameters, applied in neural learning methods, electrical digital data processing, data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

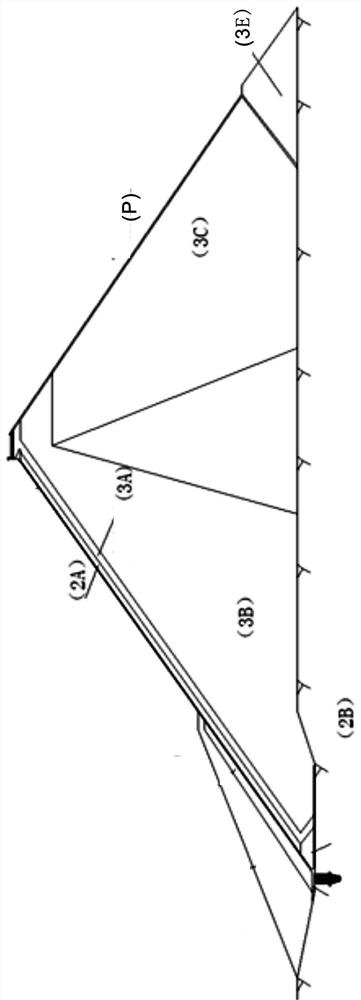

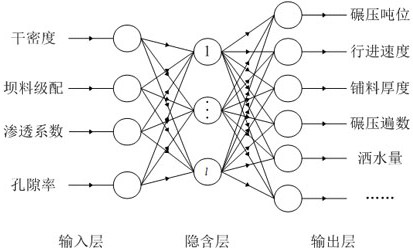

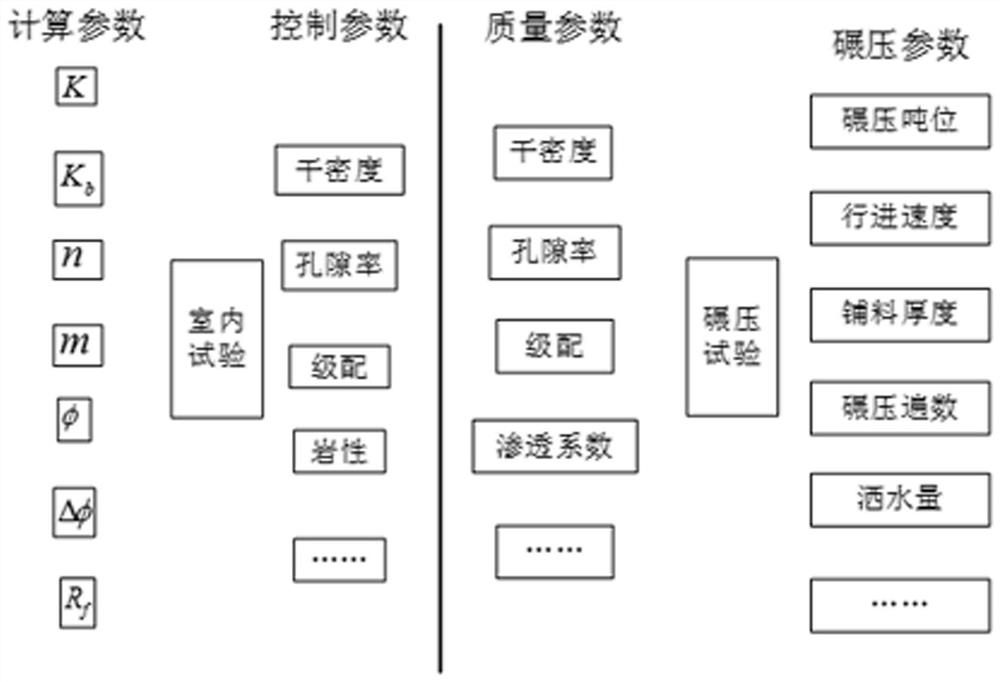

[0106] A method suitable for mutual optimization of mechanical parameters and rolling construction parameters in the rockfill dam chamber, the method includes

[0107] Establish an analysis model based on the physical and mechanical parameters of the rockfill dam material chamber to optimize the rolling construction parameters, and optimize the on-site rolling construction parameters through the analysis model to obtain the optimal on-site rolling construction parameters;

[0108] as well as

[0109] An indoor physical and mechanical parameter analysis model based on rockfill dam material rolling construction parameters optimization is established, and the indoor test mechanical parameters are predicted through the analysis model, and the physical and mechanical parameters of the rockfill material corresponding to the on-site rolling test are obtained.

[0110] The steps of the method are:

[0111] Step 1: Analyze the on-site large-scale rolling test of rockfill dam materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com