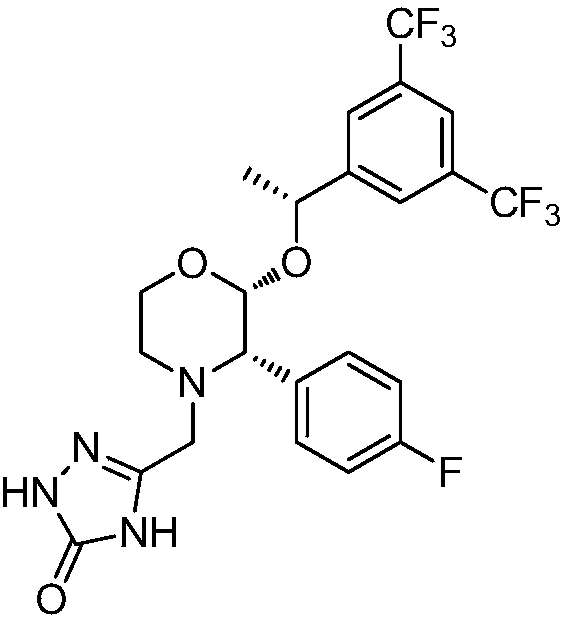

Refining preparation process of high-purity aprepitant

A preparation process and aprepitant technology, which is applied in the field of refining and preparation technology of high-purity aprepitant, can solve the problems of insignificant effect and inability to meet API impurity residues and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

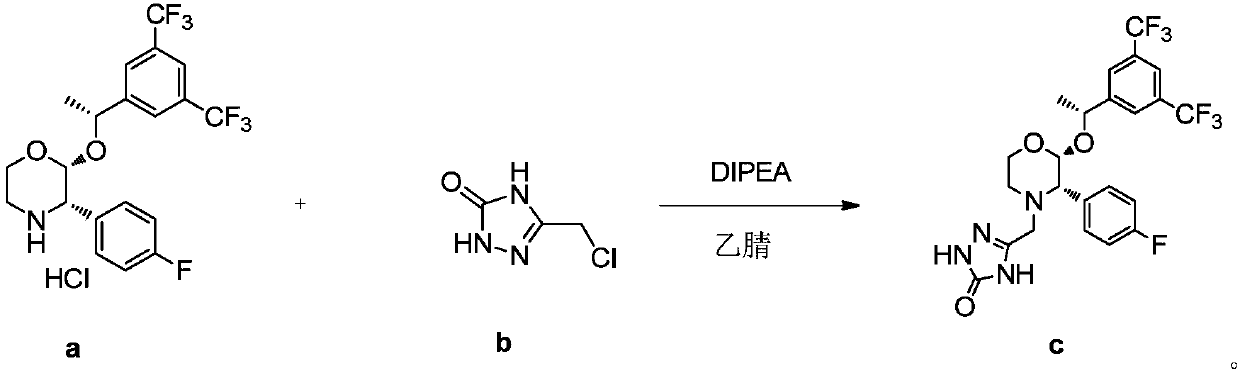

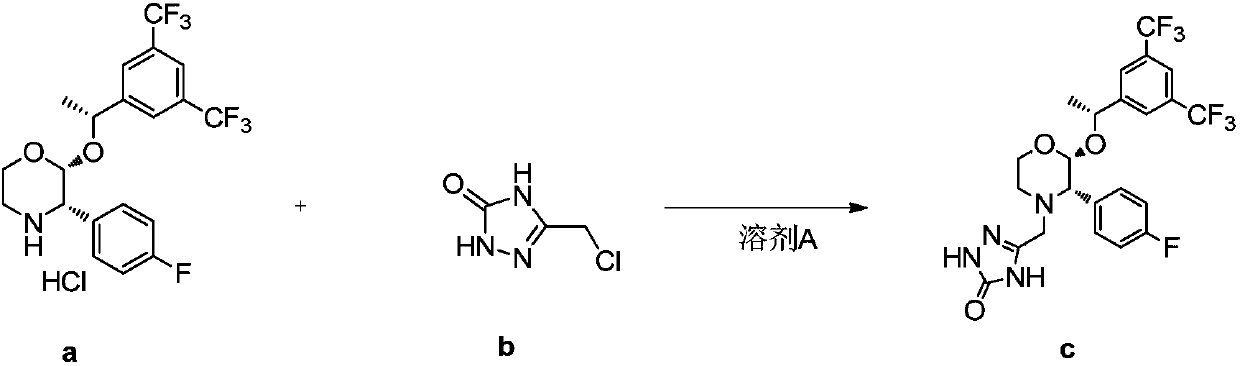

[0030] (1) Synthesis of Aprepitant Crude Product

[0031] Add 30.0 g of raw material intermediate a, 10.3 g of raw material intermediate b, and 100 ml of acetonitrile into the three-necked flask, react at 35 ° C for 1.5 h, and obtain 33 g of crude aprepitant by suction filtration, with a purity (HPLC) of 97.1%;

[0032] (2) Crude refined

[0033] Add the crude product (30g) into 600ml of methyl isobutyl ketone, heat to 50-60°C to dissolve the solid, cool to 0-10°C to crystallize for 1 hour, filter with suction, and dry under reduced pressure at 50°C to obtain the refined product of white crystals 27.5g, 91.6% yield, 99.8% purity (HPLC), maximum 0.04% impurity.

Embodiment 2

[0035] Add the crude product (18g) prepared in Example 1 into 600ml of methyl isobutyl ketone, heat to 50-60°C to dissolve the solid, cool to 0-10°C for crystallization for 1 hour, suction filter, and dry under reduced pressure at 50°C 16 g of refined white crystals were obtained, with a yield of 88%, a purity (HPLC) of 99.9%, and a maximum purity of 0.05%.

Embodiment 3

[0037] Add the crude product (18 g) prepared in Example 1 into 600 ml of 2-butanone, heat to 50-60°C to dissolve the solid, cool to 0-10°C to crystallize for 1 hour, filter with suction, and dry under reduced pressure at 50°C to obtain white The crystallized refined product was 15.7g, the yield was 87.2%, the purity (HPLC) was 99.8%, and the maximum purity was 0.06%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com