A load control method for an electric water heater

A technology of electric water heater and load control, which is applied to fluid heaters, lighting and heating equipment, etc., and can solve problems such as limited control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

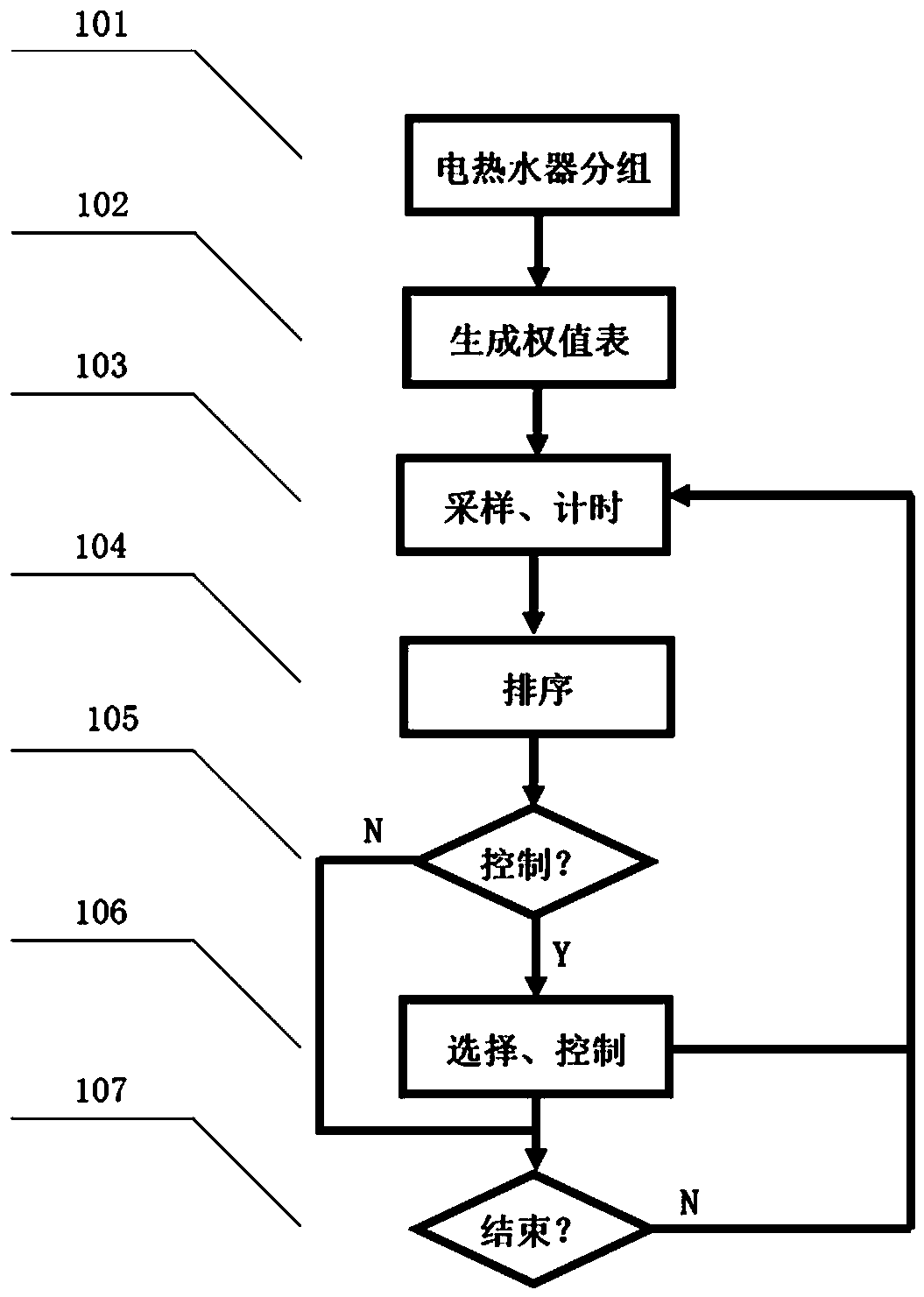

[0021] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

[0022] refer to figure 1 , this method includes the following steps:

[0023](1) First execute step 101, group the electric water heaters according to the volume of the water tank, the upper and lower limits of the temperature and the rated power, and then carry out the second grouping according to the number of users and user habits, so that each group of electric water heaters has the same volume, power, The upper and lower limits of temperature, the number of users and user habits. One group [120L, 3000W, 45°C-50°C], [160L, 3000W, 45°C-50°C], [200L, 3000W, 45°C-50°C], [279L, 4500W, 45°C] °C-50°C], [320L, 6000W, 45°C-50°C], [120L, 3000W, 50°C-55°C], [160L, 3000W, 50°C-55°C], [200L, 3000W, 50°C-55°C], [279L, 4500W, 50°C-55°C], [320L, 6000W, 50°C-55°C]. In practice, the number of users supported by an electric water heater is related to its size,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com