Mobile phone lens barrel with large air space

An air spacer and lens barrel technology, applied in installation, optics, instruments, etc., can solve the problems of increased lens weight, difficult assembly, thick gasket, etc., and achieve the effects of simplifying the assembly process, improving product yield, and reducing lens weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

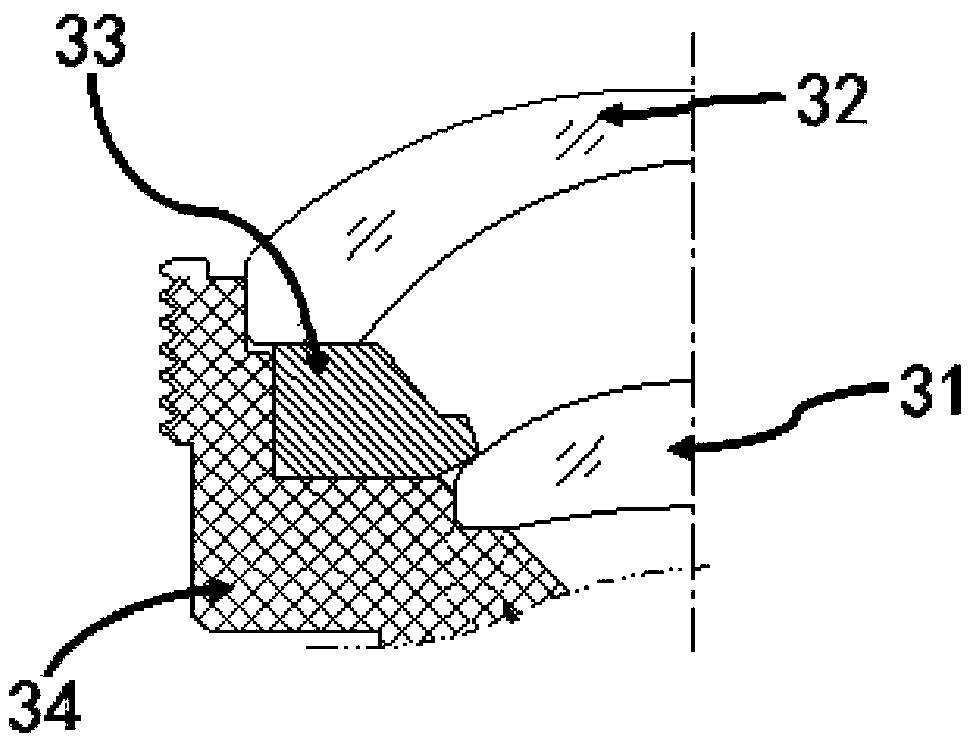

[0009] Such as figure 1 Shown is a schematic diagram of the lens air interval control of the conventional lens barrel 34. Conventional lens air separation control with a small air separation between the two lenses is controlled by adding a gasket 33 between the front lens 31 and the rear lens 32, that is, the gasket 33 presses the front lens 31 and then the latter lens 32 is assembled. However, for a lens with a large air gap between the two lenses, if a metal gasket is used to control the air gap, it will increase the weight of the lens, and the processing accuracy of the metal lens gasket is also unstable and the tolerance distribution is wide; Difficult to mold, easy to deform and unstable quality; too thick washer, assembly will be more difficult.

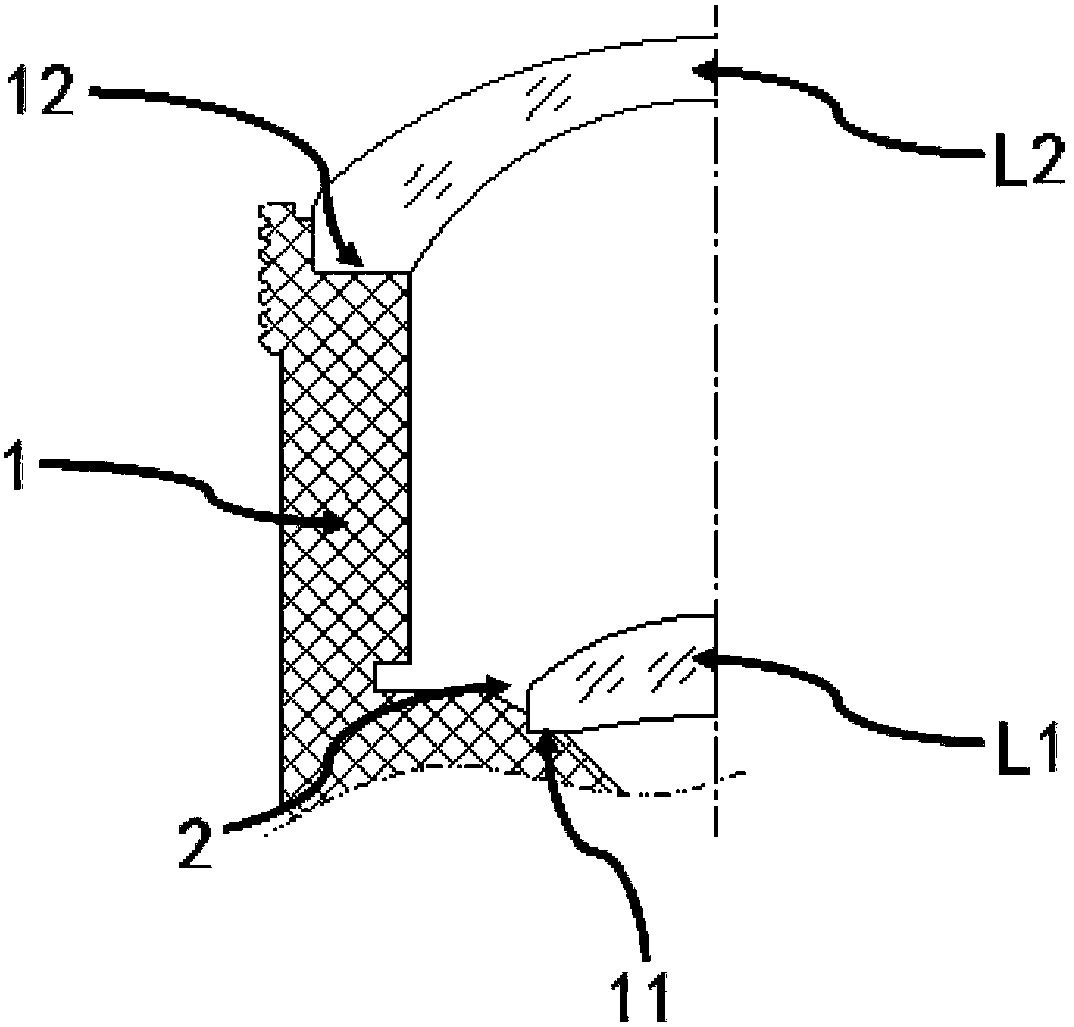

[0010] The invention provides a mobile phone lens barrel with a large air gap, such as figure 2 Shown is a schematic diagram of a mobile phone lens barrel with a large air gap according to the present invention. In the present ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap