Battery container with hole in bottom part and sealing method of battery container

A battery tank and sealing valve technology, applied in sealing materials, battery pack components, battery boxes/jackets, etc., can solve the problems of low production efficiency, long formation time, poor concentration, etc., to ensure the sealing effect and improve the formation quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

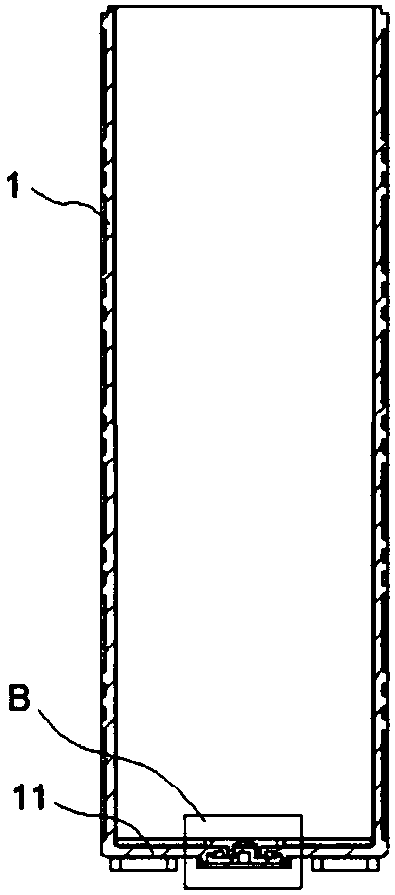

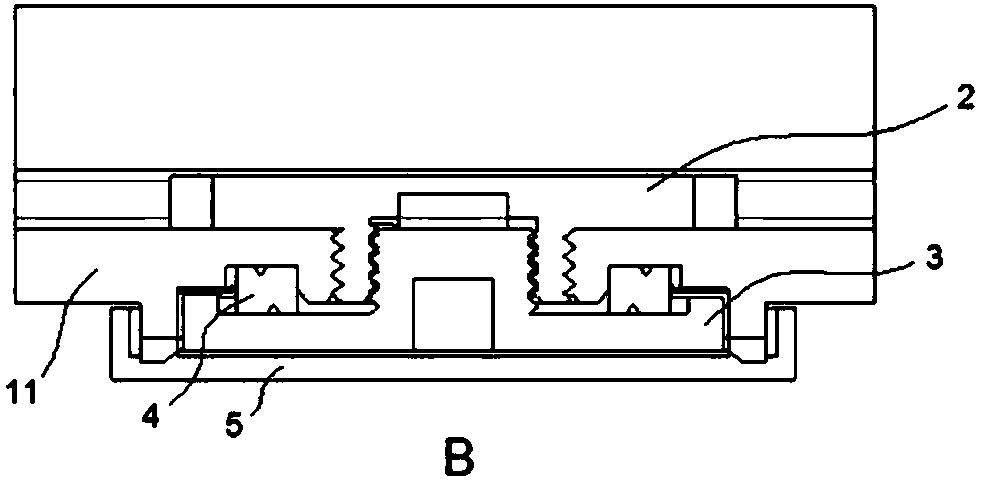

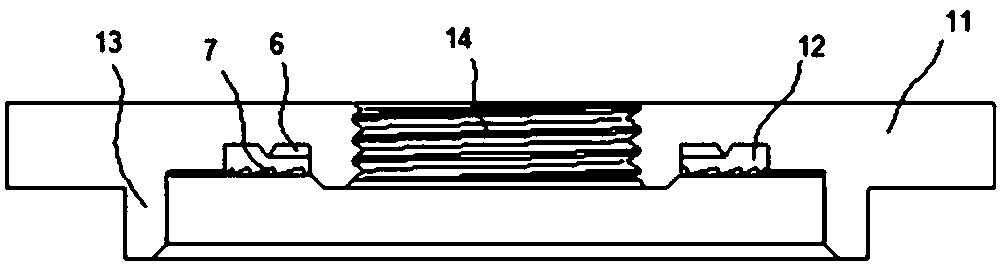

[0030] Such as Figure 1 to Figure 6 As shown, the battery tank includes a tank body 1, and the tank body 1 includes a bottom plate 11 provided with an opening 14. The inner side of the opening 14 is provided with threads, and the thread at this place is a reverse thread. There are grooves 12 and first bosses 13 . The tank body 1 is provided with a bottom cover plate 2 , and the bottom cover plate 2 includes a connection portion 21 and a diverter portion 22 threadedly connected with the opening 14 , and an internal thread 23 is provided on the connection portion 21 . The sealing valve 3 is provided with an external thread that cooperates with the internal thread 23 , and the end of the sealing valve 3 is provided with a second boss 31 . The battery tank structure also includes a sealing ring 4 and a bottom cover 5, the sealing ring 4 is compressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com