Battery pack operation method

A method of operation and technology of battery packs, applied in secondary batteries, secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the problem that battery cells have not yet reached saturation, battery cell characteristics are different, and battery cell differences are exacerbated. problems, to achieve the effect of improving service life, good performance consistency, and preventing excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

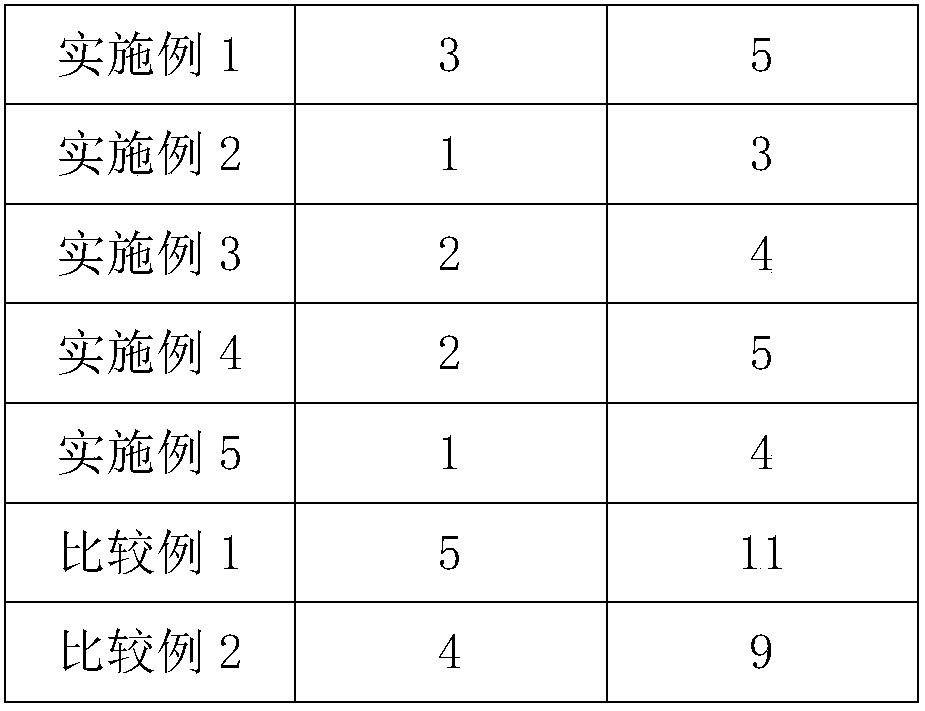

Embodiment 1

[0028] 1), detecting the voltage of each battery in the battery pack, when detecting that the voltage of the single battery is lower than 90% of the average value of the batteries in the battery pack, isolating the single battery from the battery pack;

[0029] 2) Implement an activation procedure on the single battery, and heat the battery to be activated to 45°C;

[0030] a) Discharge the battery to be activated to a cut-off voltage of 2.7V;

[0031] b) Activate by positive / negative alternating pulse current, the positive pulse current is 0.1C, the pulse time is 10s, the negative pulse current is 0.1C, the pulse time is 10s, and the interval between positive and negative pulse currents 5s, the activation time is 3h;

[0032] c), charging the battery at 2C for 5min, then charging at 0.1C for 2h, alternately charging to a cut-off voltage of 4.2V;

[0033] d) Activate by positive / negative alternating pulse current, the positive pulse current is 0.1C, the pulse time is 10s, th...

Embodiment 2

[0037] 1) Detect the voltage of each battery in the battery pack, and when it is detected that the voltage of the single battery is lower than 85% of the average value of the batteries in the battery pack, the single battery is isolated from the battery pack;

[0038] 2) Implement an activation procedure on the single battery, and heat the battery to be activated to 55°C;

[0039] a) Discharge the battery to be activated to a cut-off voltage of 2.7V;

[0040] b) Activate by positive / negative alternating pulse current, the positive pulse current is 0.5C, the pulse time is 1s, the negative pulse current is 0.5C, the pulse time is 1s, and the interval between positive and negative pulse currents 10s, the activation time is 1h;

[0041] c), charging the battery at 5C for 1min, then charging at 0.2C for 0.1h, alternately charging to a cut-off voltage of 4.2V;

[0042] d) Activate by positive / negative alternating pulse current, the positive pulse current is 0.5C, the pulse time is...

Embodiment 3

[0046] 1), detecting the voltage of each battery in the battery pack, when it is detected that the voltage of the single battery is lower than 80% of the average value of the batteries in the battery pack, the single battery is isolated from the battery pack;

[0047] 2) Implement an activation procedure on the single battery, and heat the battery to be activated to 50°C;

[0048] a) Discharge the battery to be activated to a cut-off voltage of 2.7V;

[0049] b) Activate by positive / negative alternating pulse current, the positive pulse current is 0.3C, the pulse time is 5s, the negative pulse current is 0.4C, the pulse time is 5s, and the interval between positive and negative pulse currents 5s, the activation time is 2h;

[0050] c), charging the battery at 3C for 4min, then charging at 0.1C for 1h, alternately charging to a cut-off voltage of 4.2V;

[0051] d), using positive / negative alternating pulse current for activation, the positive pulse current is 0.3C, the pulse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com