A kind of maintenance method of capacity recovery type lithium ion battery

A lithium-ion battery and capacity recovery technology, applied in the direction of secondary battery repair/maintenance, can solve the problems of insignificant capacity recovery effect, affecting lithium-ion de-intercalation reaction, etc., and achieve the effect of simple design and battery capacity recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment one, heating method.

[0047] Commercial LiCoO 2 As the cathode active material, acetylene black is used as the conductive agent, PVDF is used as the binder, and according to LiCoO 2 : Acetylene black: PVDF=92:3:5 mass ratio, weigh and mix evenly, use NMP as dispersant, prepare slurry according to solid matter:NMP=60:40 mass ratio, stir evenly and spread on aluminum foil , after being dried at 80°C and rolled at 100MPa, it was cut into positive electrode sheets. Take commercial modified natural graphite as the anode active material, take acetylene black as the conductive agent, and styrene-butadiene latex as the binder, according to the mass ratio of graphite: acetylene black: styrene-butadiene latex = 92:3:5, weigh and mix evenly, Using deionized water as a dispersant, prepare a slurry according to the mass ratio of solid matter:NMP=60:40, stir evenly and spread it on a copper foil, dry it at 80°C, roll it at 80MPa, and cut it into negative electrode sheet...

Embodiment 2

[0050] Embodiment two, freezing method

[0051] Take Commercial LiMn 2 o 4 As the cathode active material, acetylene black was used as the conductive agent, PVDF was used as the binder, and other components and assembly methods of the battery were the same as in Example 1, except that 0.5% by mass of propylene carbonate was added as the SEI film-forming agent. Assembled into a battery with a capacity of 1Ah. The capacity dropped to 650mAh after 500 cycles at 2C rate. Discharge the battery to a voltage of 3.0V, open the valve and place the battery in a thermostat at minus 20°C for 24 hours, then put it at room temperature for 8 hours. Add LiPF at a concentration of 1mol / L 6 -EC / EMC / DEC (volume ratio 1:1:1) electrolyte, which contains 1% mass ratio of propylene carbonate as SEI film-forming agent, the amount of electrolyte added accounts for 1% of the battery shell except for electrodes, separators, and raw materials. 80% of the remaining space outside the electrolyte. Aft...

Embodiment 3

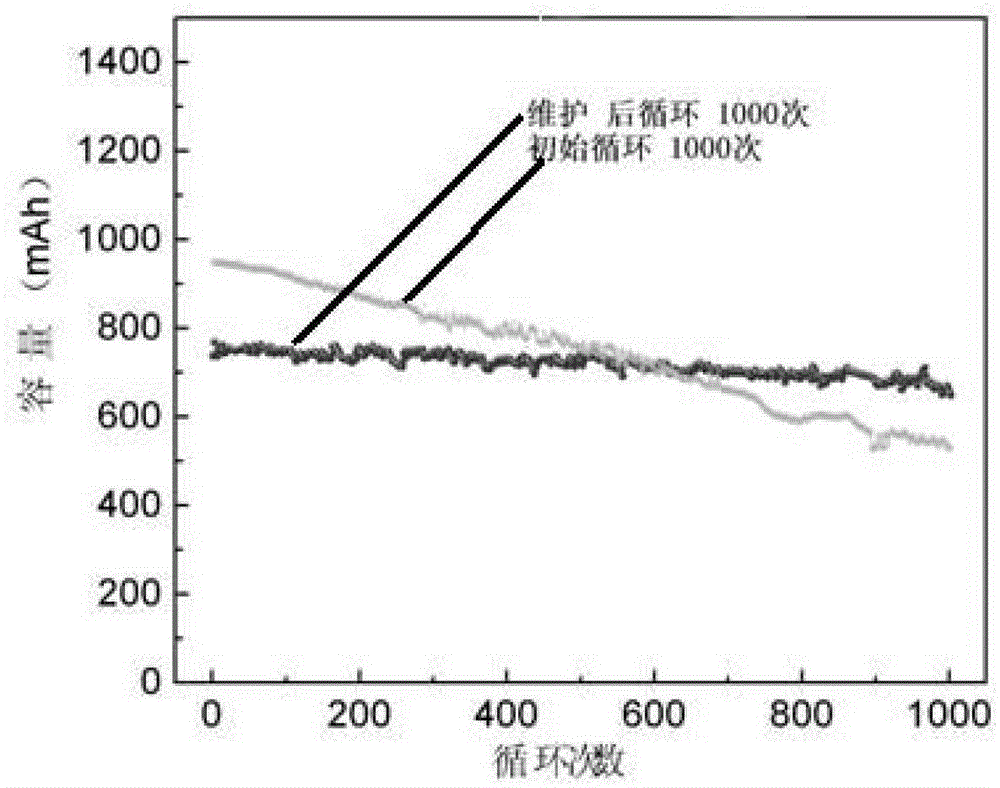

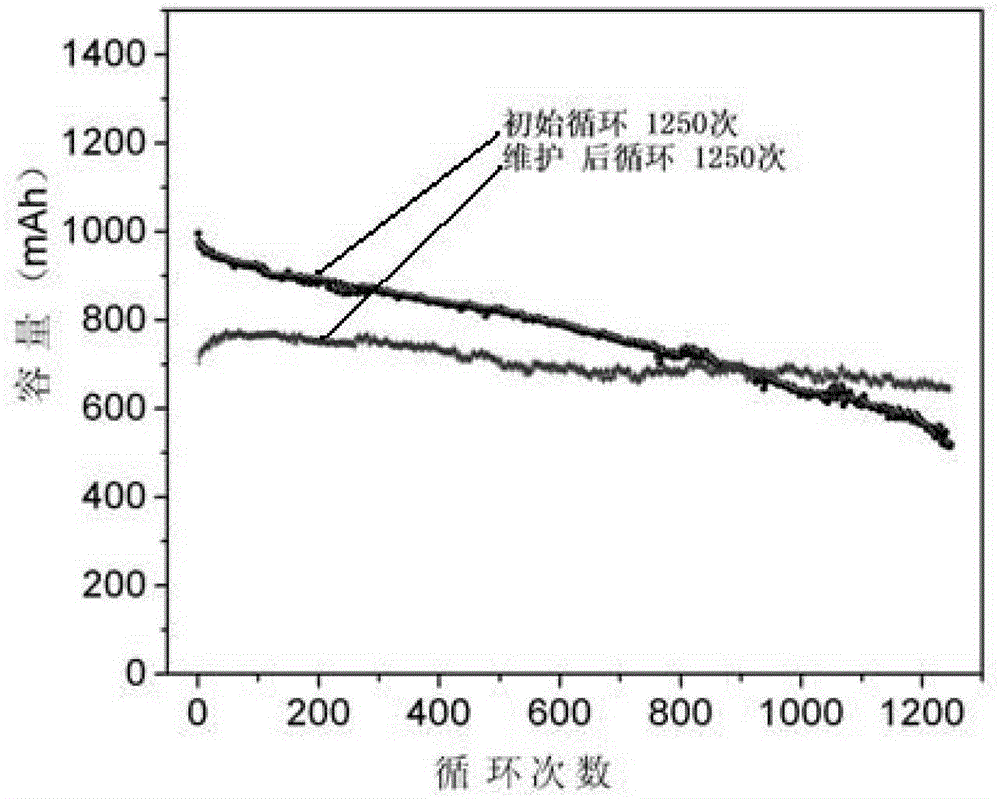

[0054] Embodiment three, ultrasonic method

[0055] Commercial LiCo 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 As the cathode active material, acetylene black was used as the conductive agent, PVDF was used as the binder, and other components and assembly methods of the battery were the same as in Example 1, except that 0.5% by mass vinyl sulfite was added as the SEI film-forming agent. Assembled into a battery with a capacity of 1Ah. The capacity drops to 750mAh after 1000 cycles at 2C rate. Discharge the battery to a voltage of 3.0V, and place the battery in an ultrasonic container for 15 minutes after opening the valve. Add LiPF at a concentration of 1mol / L 6 -EC / EMC / DEC (volume ratio 1:1:1) electrolyte, which contains 5% by mass of vinyl sulfite as SEI film-forming agent, and the amount of electrolyte added accounts 80% of the remaining space outside the electrolyte. After leaving the battery for 8 hours, charge it to 4.3V with a constant current of 200mA, discharge it at a constant cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com