Tubular upper intake air type air curtain machine

A technology of upward air intake and air curtain machine, which is applied in the direction of mechanical equipment, non-variable pumps, machines/engines, etc., and can solve problems such as only horizontal air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

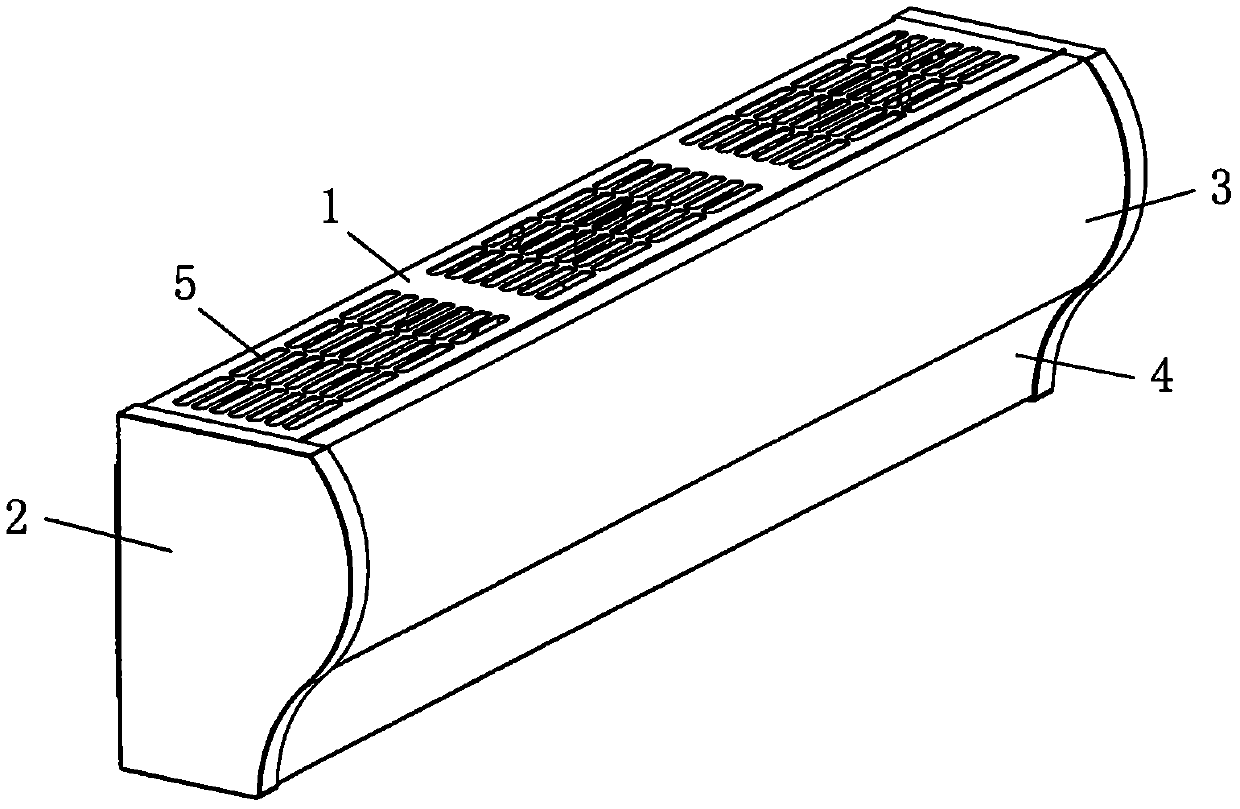

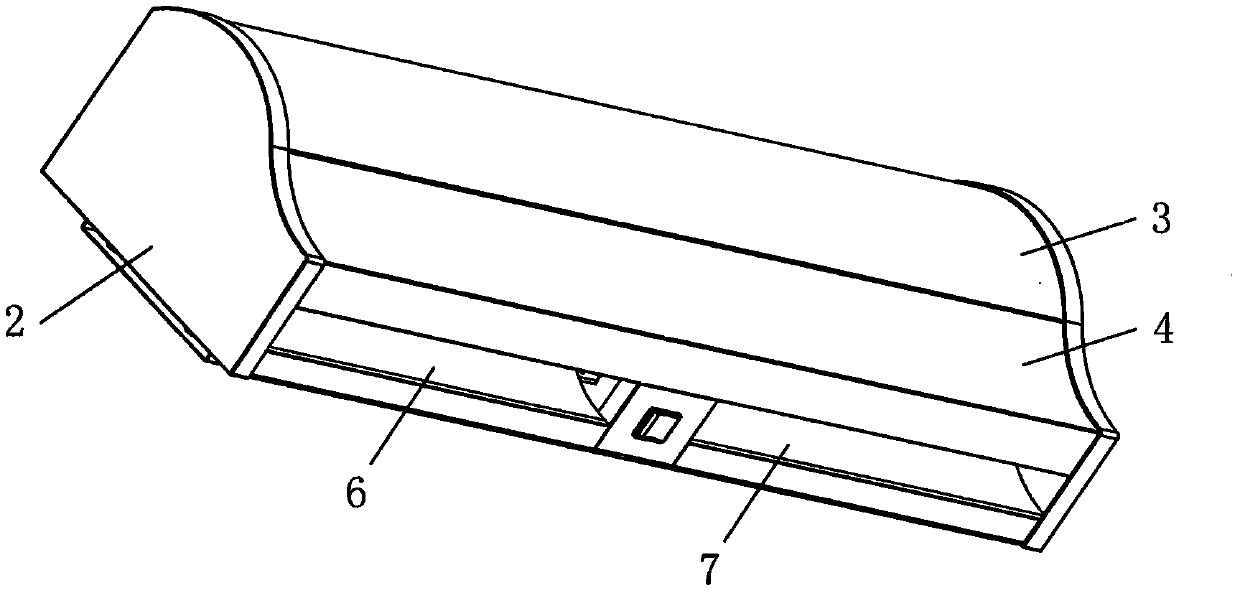

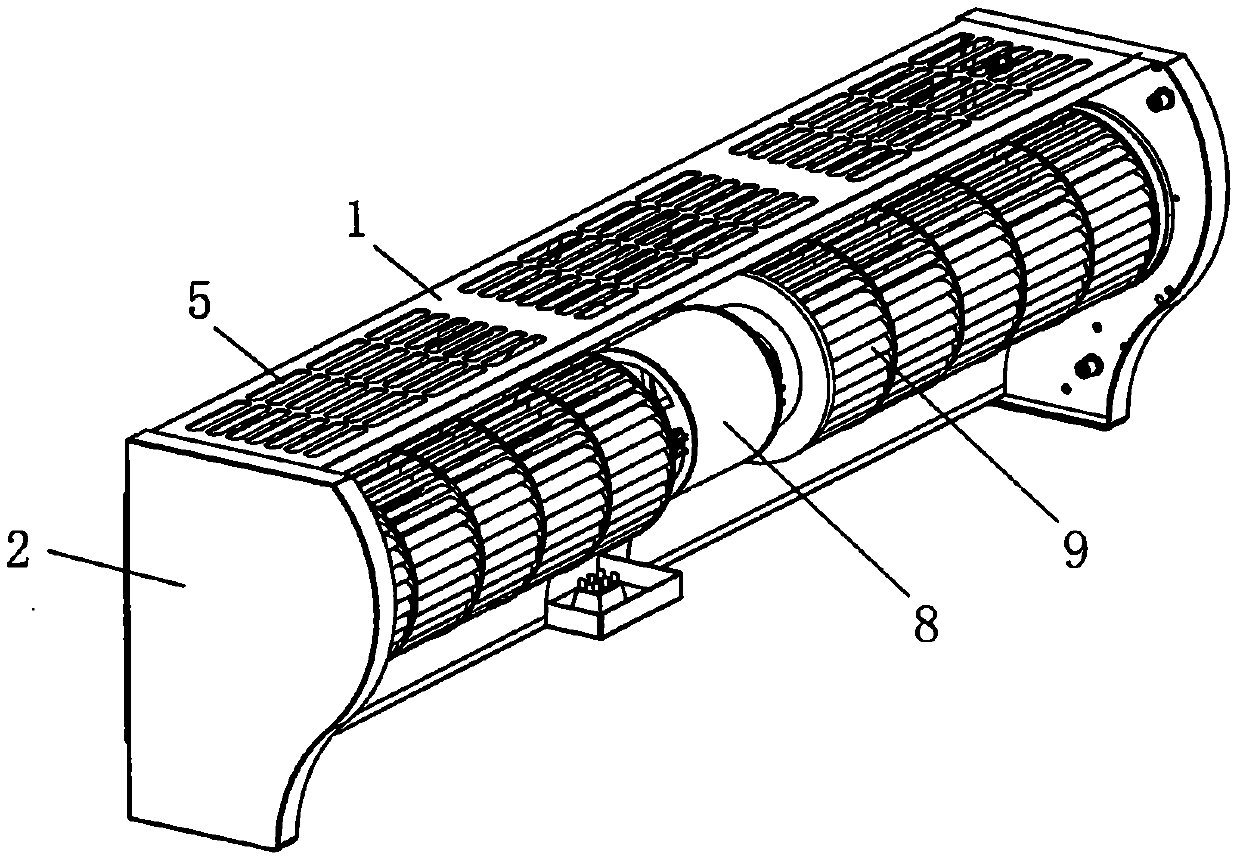

[0020] see Figure 1-Figure 6 , the cross-flow upward wind-intake air curtain machine, including a casing, and a motor 8 and an impeller 9 arranged in the inner cavity of the casing, the top and bottom of the casing are respectively provided with an air inlet 5 and an air outlet connected to the inner cavity 6. The casing includes a panel with a wavy inner wall, and the wind generated by the impeller 9 is blown along the wavy inner wall of the panel. The motor 8 of this structure drives the impeller to rotate in the opposite direction (clockwise), and then utilizes the wave-shaped inner wall on the panel as an air channel to supply air to realize the effect of upward air intake.

[0021] Further, the panel is formed by connecting the upper panel 3 and the lower panel 4 up and down, the upper panel 3 is provided with an arc-shaped inner wall with a sect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap