Pile foundation construction method of large angle bevel hard rock stratum

A technology of hard rock formations and construction methods, applied in the field of pile foundation construction, can solve the problems of long construction period, inability to effectively solve drilling, eccentricity, etc., and achieve the effect of protecting conductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

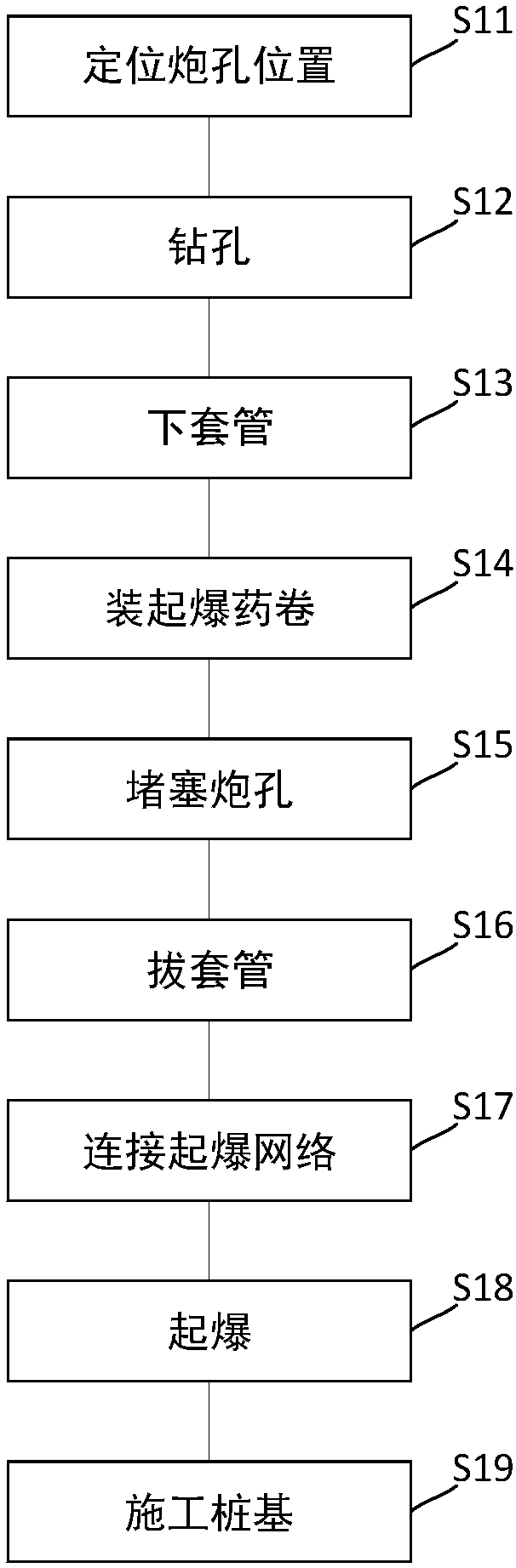

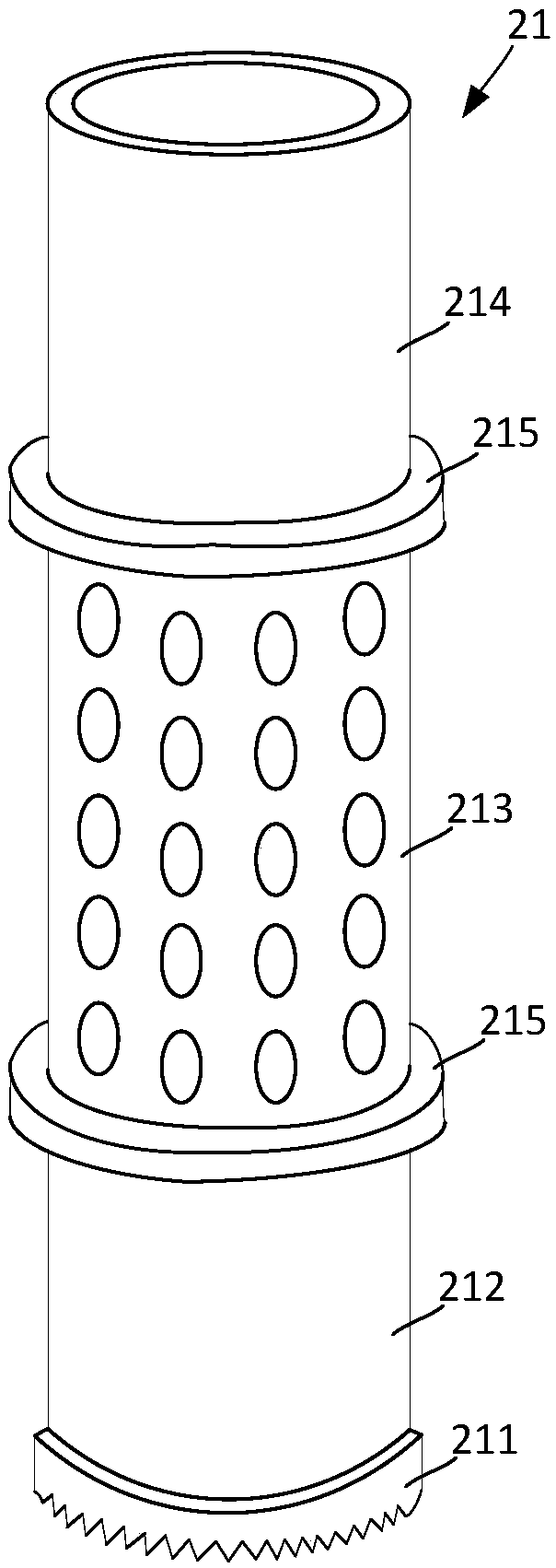

[0035] refer to figure 1 , The invention provides a pile foundation construction method for a large-angle slope and a hard rock formation, which is used to solve the problem that drilling eccentricity is likely to occur during pile foundation construction on a slope rock formation with a large-angle slope. The construction method of the present invention forms blastholes by drilling with geological drilling rigs, uses the casing method to install the primary explosive roll, and adopts the method of shaft-type full-section differential blasting to loosen the slope rock formations and break the rock formations with high hardness and large-angle slopes to form gentle surface, so as to provide a flat working surface for the drilling construction of the pile foundation, and effectively solve the problem of drilling eccentricity. Below in conjunctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com