Protection method for preventing initiating explosive device of docking mechanism from being detonated beforehand

A technology for docking mechanism and pyrotechnics, which is applied in the test of ammunition, weapon accessories, ammunition, etc., to achieve the effects of high reliability, proper protection measures and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

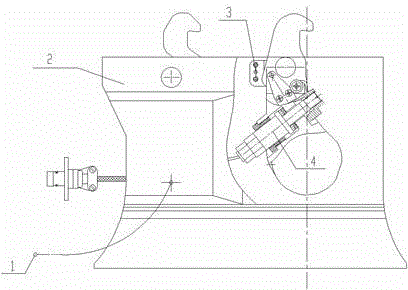

[0021] A preferred embodiment of the present invention takes the pyrotechnic product for docking lock in the docking mechanism as an example:

[0022] Strictly control the site before assembling pyrotechnics. The temperature of the assembly site is 15~25°C, and the relative humidity is kept at 20%~60%. , and equipped with an electrostatic wristband; fireworks are strictly prohibited in the venue, and the fire-fighting facilities should be complete and within the validity period.

[0023] Before assembling the pyrotechnic product, process an M3 process grounding threaded hole in the lower part of the docking lock housing; then connect one end of the anti-static process cable to the M3 process grounding threaded hole of the product through the mounting screw M3, and connect the other end to the grounding pile to complete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com