Calibration burning method and device for camera

A programming method and camera technology, applied in the field of photography, can solve problems such as affecting the calibration accuracy, poor uniformity of calibration light brightness, and inability to calibrate and programming with a wide-angle camera module, so as to ensure brightness uniformity and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

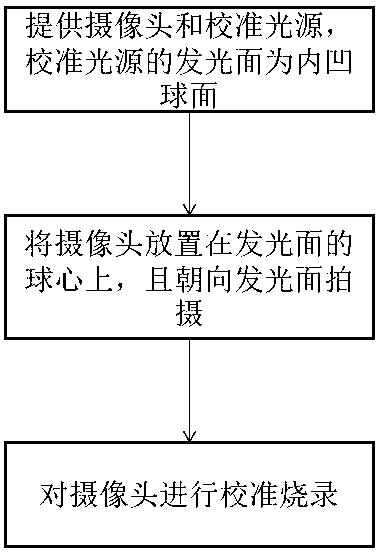

[0029] like figure 1 and 2 As shown, a calibration burning method of camera 2 includes:

[0030] Step 1: Provide a camera 2 and a calibration light source 1, the calibration light source 1 has a light-emitting surface 2, and the light-emitting surface 2 is a concave spherical surface;

[0031] Step 2: placing the camera 2 on the center of the sphere of the light-emitting surface 2, and shooting towards the light-emitting surface 2, the light-emitting surface 2 at least covers the viewing angle range of the camera 2;

[0032] Step 3: Calibrate and burn camera 2.

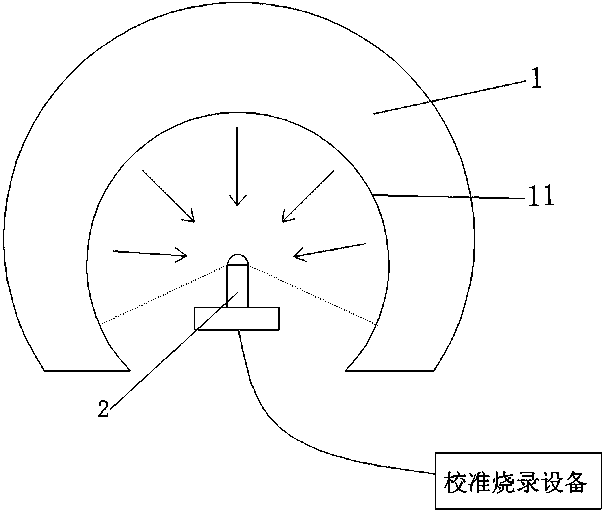

[0033] The calibration burning method adopts a calibration light source 1 whose light-emitting surface 2 is a concave spherical surface to calibrate and burn the camera 2. The distances from each point on the light-emitting surface 2 to the camera 2 are the same, which can maximize the Ensure the brightness uniformity of the calibration light to reduce the error of the calibration parameters caused by the brightnes...

Embodiment 2

[0039] like figure 2 As shown, a calibration burning device for camera 2 includes:

[0040] The calibration light source 1 is used to provide the camera 2 with the calibration light required for calibration and burning, which has a light-emitting surface 2, and the light-emitting surface 2 is a concave spherical surface;

[0041] The bracket is used to support and fix the camera 2, so that the camera 2 is located on the center of the sphere of the light-emitting surface 2;

[0042] Calibration and burning equipment, used to control the camera 2 to perform calibration and burning in the calibration light source 1;

[0043] Wherein, the calibration burning device is electrically connected to the camera module.

[0044] The color temperature and / or illuminance of the calibration light source 1 can be adjusted. In actual implementation, LEDs with different color temperatures can be evenly distributed on the light-emitting surface 2, and the color temperature of the calibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com